A new self-powered, wristwatch-style health monitor can track a wearer’s pulse and wirelessly communicate with a nearby smartphone or tablet—all without needing an external power source or a battery.

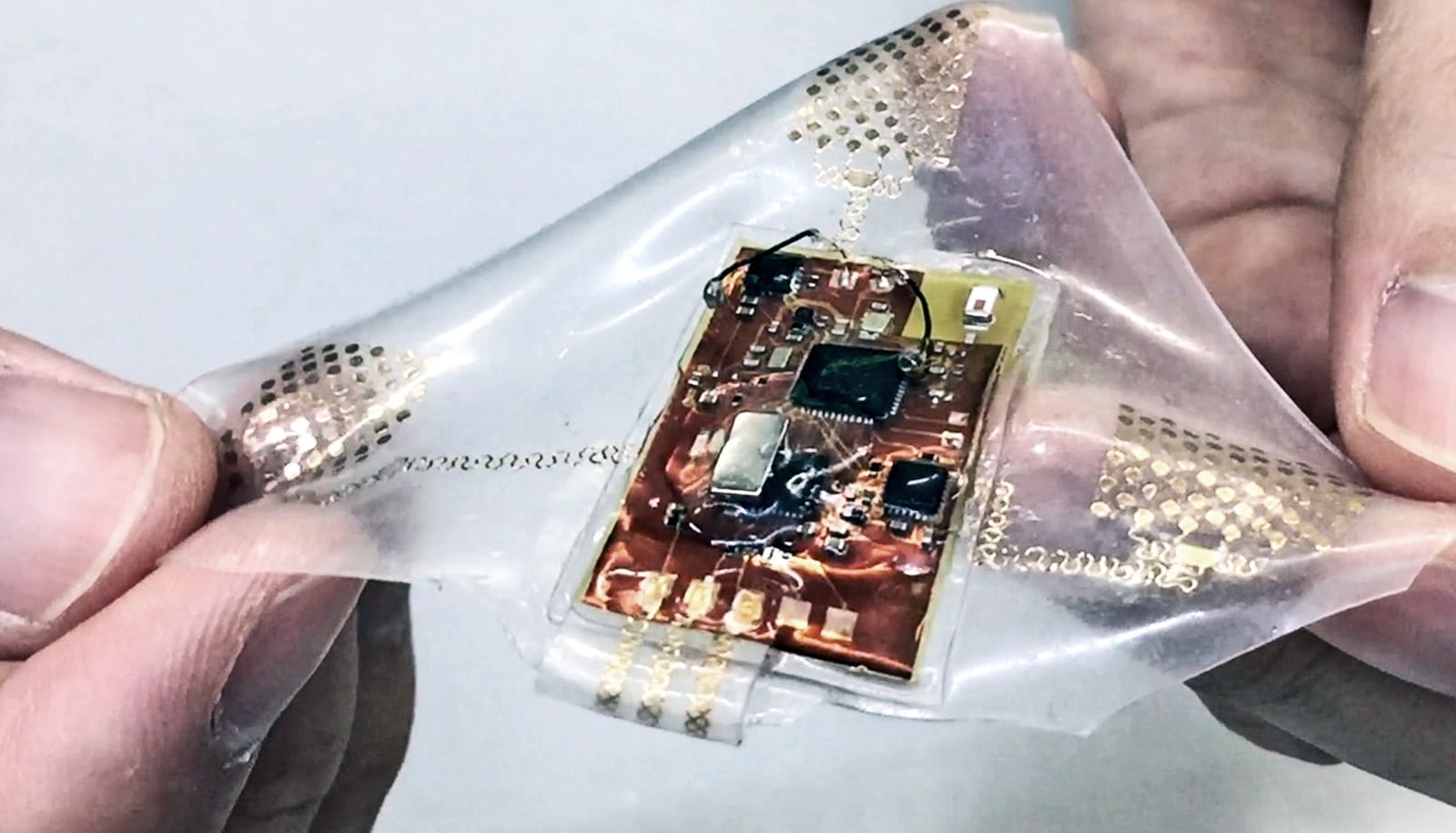

In a paper in the journal Nano Energy, researchers describe their invention, built via 3D printing of nanomaterials on flexible substrates for real-time and wireless monitoring of vital signs.

The current prototype serves as a self-powered radial artery pulse monitor, but other aspects of health—such as heart rate, body temperature, or blood pressure—can be gauged by simply changing the sensor circuitry, the researchers say.

“Imagine you’re out working in a remote location—anywhere, the desert on a mission, in mountains hiking, or even a space station, for example—and you need to keep track of your health information on demand, or there’s an incident, and you need to monitor someone’s vital signs urgently and accurately.

“This self-powered and wireless device allows you to do that without relying on a battery that can lose its charge and has the thermal runaway issue [overheating of lithium-ion batteries that can lead to combustion],” says senior coauthor Rahim Esfandyar-Pour, assistant professor of electrical engineering and computer science and biomedical engineering at the University of California, Irvine.

The device delivers health information in two ways. In one mode, the energy created by tapping the wristband’s nano energy generators powers up the sensor circuitry, and soon the wearer’s pulse rate appears as flashing signals on an LED display.

The second mode works when a smartphone or similar device is held near the wearable. Embedded near-field communication technology facilitates the wireless exchange of both power and data between the wristband and the mobile device, and biophysical information is plotted and displayed on the smartphone’s screen.

The on-demand and self-powered characteristics of the invention are made possible by triboelectric nanogenerators that produce voltage through mechanical thumping or pressure. The TENGs are fabricated using titanium-based MXenes, a relatively new class of ultrathin 2D material with unique electrical and mechanical properties. Only a few atoms thick, MXene layers are bendable, are stretchable, and can be printed onto the surface of flexible, bandage-like material or a wearable arm- or wristband.

“This innovation achieves many significant outcomes in one package,” Esfandyar-Pour says. “It enables continuous, battery-free, wireless and on-demand health monitoring anytime and anywhere. It’s made with low-cost and flexible materials and can be tailored to meet a variety of wearable bioelectronic sensors’ requirements. It’s a flexible, completely configurated system.”

Additional authors include Prativa Das and Sang Won Lee, postdoctoral scholars in electrical engineering and computer science; and PhD students Qian Yi, Xiaochang Pei, and Huiting Qin.

The Henry Samueli School of Engineering funded the work.

Source: UC Irvine