A new method produces soft, recyclable fibers for smart textiles, say researchers.

Smart textiles offer many potential wearable technology applications, including therapeutics, sensing, and communication. For such intelligent textiles to work well, they need to be strong, stretchable, and electrically conductive. However, fabricating fibers that possess these three properties is challenging and requires complex conditions and systems.

Drawing inspiration from how spiders spin silk to make webs, a team of researchers led by assistant professor Tan Swee Ching from the department of materials science and engineering in the NUS College of Design and Engineering, has developed a way to produce soft fibers that possess these three key properties. Those fibers are also easily reused to produce new fibers.

“Technologies for fabricating soft fibers should be simple, efficient, and sustainable to meet the high demand for smart textile electronics. Soft fibers created using our spider-inspired method of spinning has been demonstrated to be versatile for various smart technology applications. For example, these functional fibers can be incorporated into a strain-sensing glove for gaming purposes, and a smart face mask to monitor breathing status for conditions such as obstructive sleep apnea. These are just some of the many possibilities,” says Tan.

The team reports their findings in Nature Electronics.

Spinning like spiders

Conventional artificial spinning methods to fabricate synthetic fibers require high pressure, high energy input, large volumes of chemicals, and specialized equipment. Moreover, the resulting fibers typically have limited functions.

In contrast, the spider silk spinning process is highly efficient and can form strong and versatile fibers under room temperature and pressure. To address the current technological challenges, the team decided to emulate this natural spinning process to create one-dimensional (1D) functional soft fibers that are strong, stretchable, and electrically conductive. They identified two unique steps in spider silk formation that they could mimic.

Spider silk formation involves the change of a highly concentrated protein solution, known as a silk dope, into a strand of fiber. The researchers first identified that the protein concentration and interactions in the silk dope increase from dope synthesis to spinning. The second step that they identified was that the arrangement of proteins within the dope changes when triggered by external factors to help separate the liquid portion from the silk dope, leaving the solid part—the spider silk fibers. This second step is known as liquid-solid phase separation.

The team recreated the two steps and developed a new spinning process known as the phase separation-enabled ambient (PSEA) spinning approach.

The soft fibers were spun from a viscous gel solution comprised of polyacrylonitrile (PAN) and silver ions—referred to as PANSion—dissolved in dimethylformamide (DMF), a common solvent. This gel solution is known as the spinning dope, which forms into a strand of soft fiber through the spinning process when the gel is pulled and spun under ambient conditions.

Once the PANSion gel is pulled and exposed to air, water molecules in the air act as a trigger to cause the liquid portion of the gel to separate in the form of droplets from the solid portion of the gel, this phenomenon is known as the non-solvent vapor-induced phase separation effect. When separated from the solid fiber, the droplets of the liquid portion are removed by holding the fiber vertically or at an angle for gravity to do its work.

“Fabrication of 1D soft fibers with seamless integration of all-round functionalities is much more difficult to achieve and requires complicated fabrication or multiple post-treatment processes. This innovative method fulfills an unmet need to create a simple yet efficient spinning approach to produce functional 1D soft fibers that simultaneously possess unified mechanical and electrical functionalities,” says Tan.

Strong, stretchy, conductive

The biomimetic spinning process combined with the unique formulation of the gel solution allowed the researchers to fabricate soft fibers that are strong, stretchable, and electrically conductive.

Researchers tested the mechanical properties, strength, and elasticity, of the PANSion gel through a series of stress tests and demonstrated that this remarkable innovation possessed excellent strength and elasticity. These tests also allowed the researchers to deduce that the formation of strong chemical networks between metal-based complexes within the gel is responsible for its mechanical properties.

Further analysis of the PANSion soft fibers at the molecular level confirmed its electrical conductivity and showed that the silver ions present in the PANSion gel contributed to the electrical conductivity of the soft fibers.

The team then concluded that PANSion soft fibers fulfills all the properties that would allow it to be versatile and potentially be used in a wide range of smart technology applications.

Gloves and masks

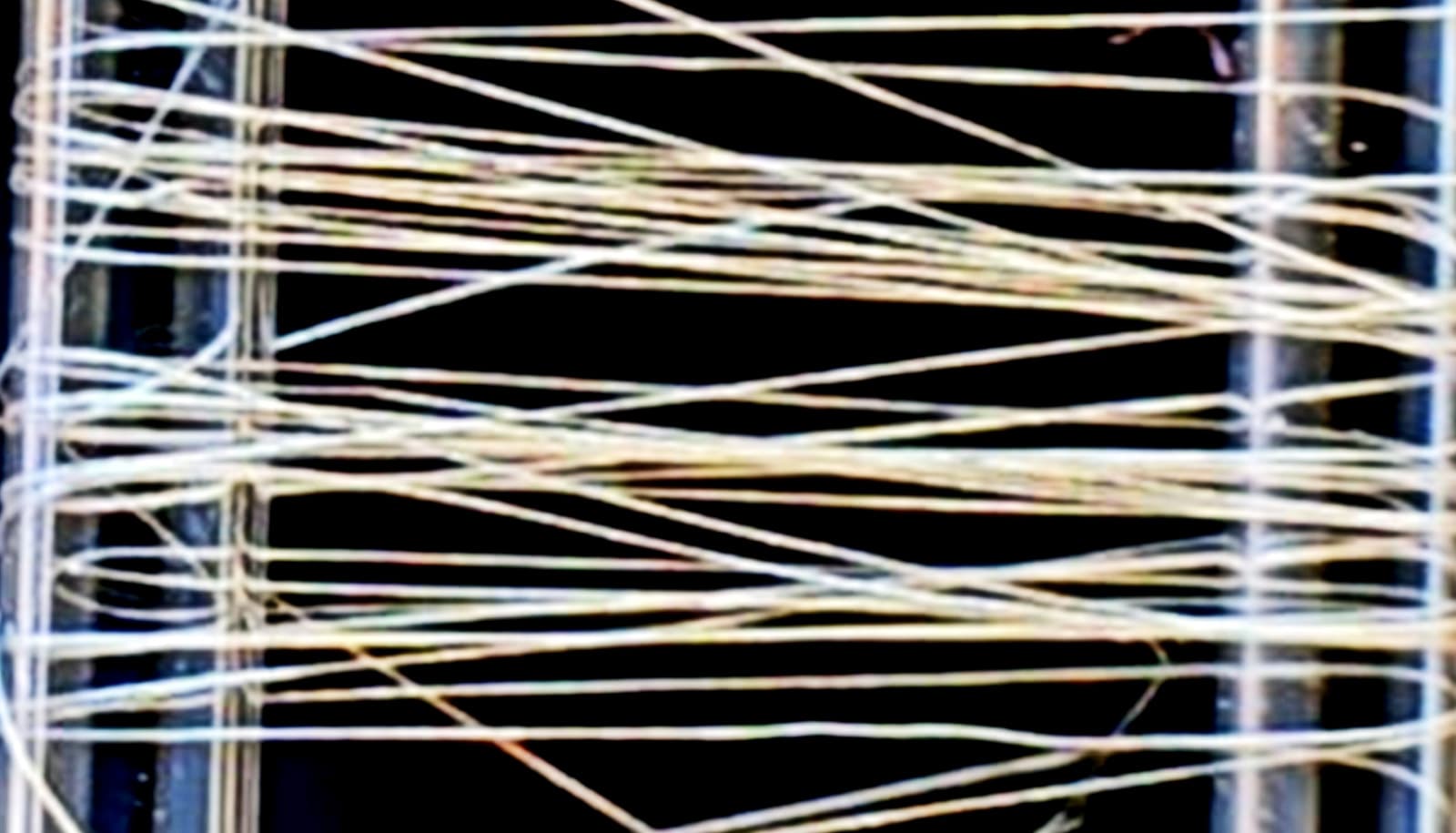

The team demonstrated the capabilities of the PANSion soft fibers in a number of applications, such as communication and temperature sensing. They sewed PANSion fibers to create an interactive glove. When connected to a computer interface, the glove could successfully detect human hand gestures and let a user play simple games.

PANSion fibers could also detect changes in electrical signals that could be used as a form of communication like Morse code. In addition, these fibers could sense temperature changes, a property that can potentially be capitalized on to protect robots from environments with extreme temperatures. Researchers also sewed PANSion fibers into a smart face mask for monitoring the breathing activities of the wearer.

On top of the wide range of potential applications of PANSion soft fibers, this innovative discovery earns points in sustainability. PANSion fibers could be recycled by dissolving in DMF, allowing it to be converted back into a gel solution for spinning new fibers. A comparison with other current fiber-spinning methods revealed that this new spider-inspired method consumes significantly lower amounts of energy and requires lower volume of chemicals.

The research team will continue to work on improving the sustainability of the PANSion soft fibers throughout its production cycle, from the raw materials to recycling the final product.

Source: NUS