A new technique uses light and magnetic fields to remotely control the movement of soft robots, lock them into position for as long as needed, and later reconfigure the robots into new shapes, researchers report.

“We’re particularly excited about the reconfigurability,” says Joe Tracy, a professor of materials science and engineering at North Carolina State University and corresponding author of a paper on the work.

“By engineering the properties of the material, we can control the soft robot’s movement remotely; we can get it to hold a given shape; we can then return the robot to its original shape or further modify its movement; and we can do this repeatedly. All of those things are valuable, in terms of this technology’s utility in biomedical or aerospace applications.”

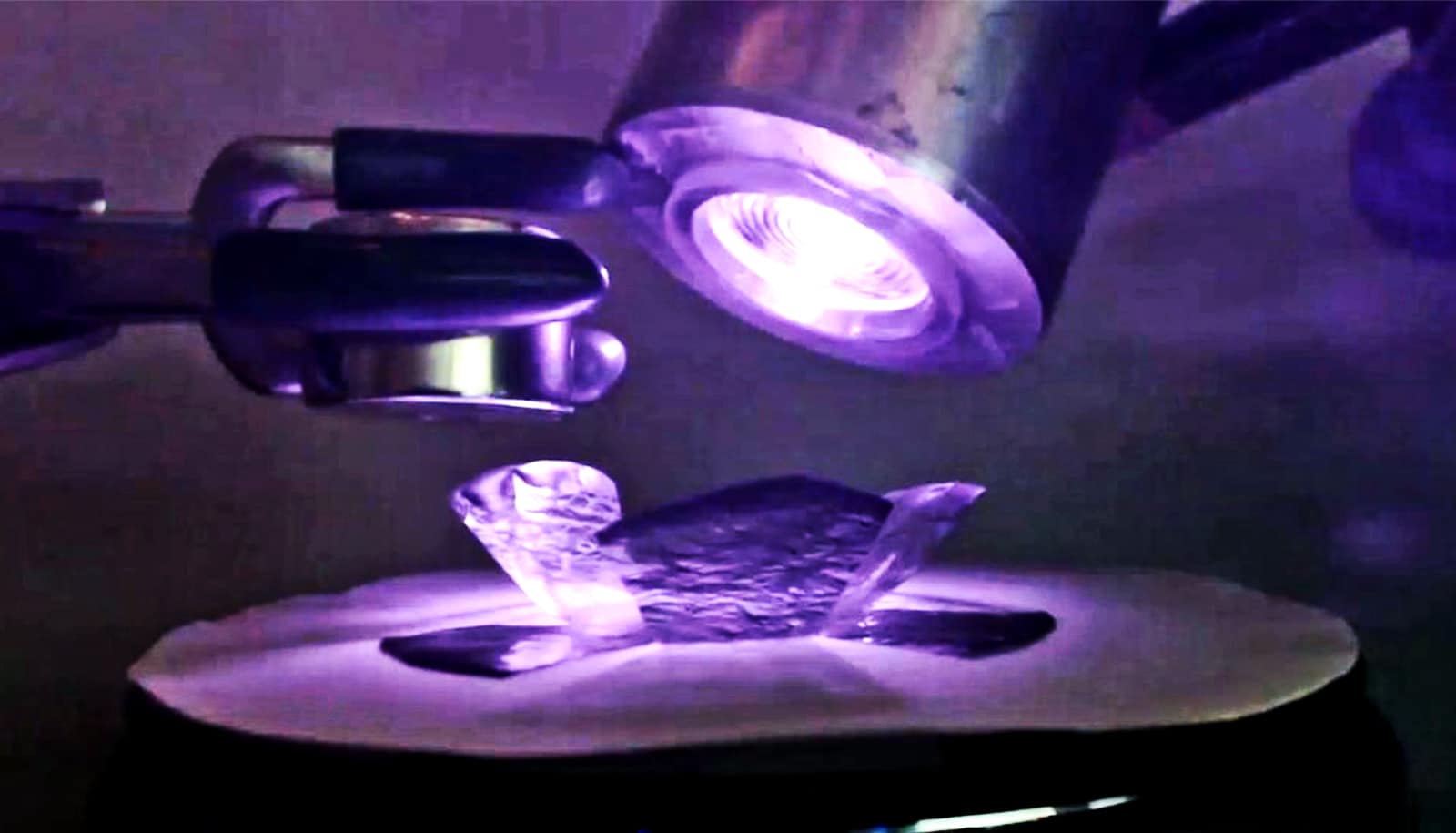

For this work, the researchers used soft robots made of a polymer embedded with magnetic iron microparticles. Under normal conditions, the material is relatively stiff and holds its shape. However, researchers can heat up the material using light from a light-emitting diode (LED), which makes the polymer pliable. Once pliable, researchers demonstrated that they could control the shape of the robot remotely by applying a magnetic field. After forming the desired shape, researchers could remove the LED light, allowing the robot to resume its original stiffness—effectively locking the shape in place.

By applying the light a second time and removing the magnetic field, the researchers could get the soft robots to return to their original shapes. Or they could apply the light again and manipulate the magnetic field to move the robots or get them to assume new shapes.

In experimental testing, the researchers demonstrated that the soft robots could form “grabbers” for lifting and transporting objects. The soft robots could also form cantilevers, or folded into “flowers” with petals that bend in different directions.

“We are not limited to binary configurations, such as a grabber being either open or closed,” says first author Jessica Liu, a PhD student. “We can control the light to ensure that a robot will hold its shape at any point.”

In addition, the researchers developed a computational model that they can use to streamline the soft robot design process. The model allows them to fine-tune a robot’s shape, polymer thickness, the abundance of iron microparticles in the polymer, and the size and direction of the required magnetic field before constructing a prototype to accomplish a specific task.

“Next steps include optimizing the polymer for different applications,” Tracy says. “For example, engineering polymers that respond at different temperatures in order to meet the needs of specific applications.”

The paper appears in the journal Science Advances.

Additional coauthors came from NC State and Elon University. Support for the work came from the National Science Foundation, the Research Triangle MRSEC, NC State’s Analytical Instrumentation Facility, and the Duke University Shared Materials Instrumentation Facility.

Source: NC State