Researchers report successfully extracting valuable rare earth elements from waste at yields high enough to resolve issues for manufacturers while boosting their profits.

The Rice University lab of chemist James Tour introduced its flash Joule heating process several years ago to produce graphene from any solid carbon source. They’ve now applied the process to three sources of rare earth elements—coal fly ash, bauxite residue, and electronic waste—to recover rare earth metals, which have magnetic and electronic properties critical to modern electronics and green technologies.

The researchers say their process is kinder to the environment by using far less energy and turning the stream of acid often used to recover the elements into a trickle.

The study appears in Science Advances.

Rare earth elements (REE) aren’t actually rare. One of them, cerium, is more abundant than copper, and all are more abundant than gold. But these 15 lanthanide elements, along with yttrium and scandium, are widely distributed and difficult to extract from mined materials.

“The US used to mine rare earth elements, but you get a lot of radioactive elements as well,” Tour says. “You’re not allowed to reinject the water, and it has to be disposed of, which is expensive and problematic. On the day the US did away with all rare earth mining, the foreign sources raised their price tenfold.”

So there’s plenty of incentive to recycle what’s been mined already, he says. Much of that is piled up or buried in fly ash, the byproduct of coal-fired power plants.

“We have mountains of it,” he says. “The residue of burning coal is silicon, aluminum, iron, and calcium oxides that form glass around the trace elements, making them very hard to extract.” Bauxite residue, sometimes called red mud, is the toxic byproduct of aluminum production, while electronic waste is from outdated devices like computers and smartphones.

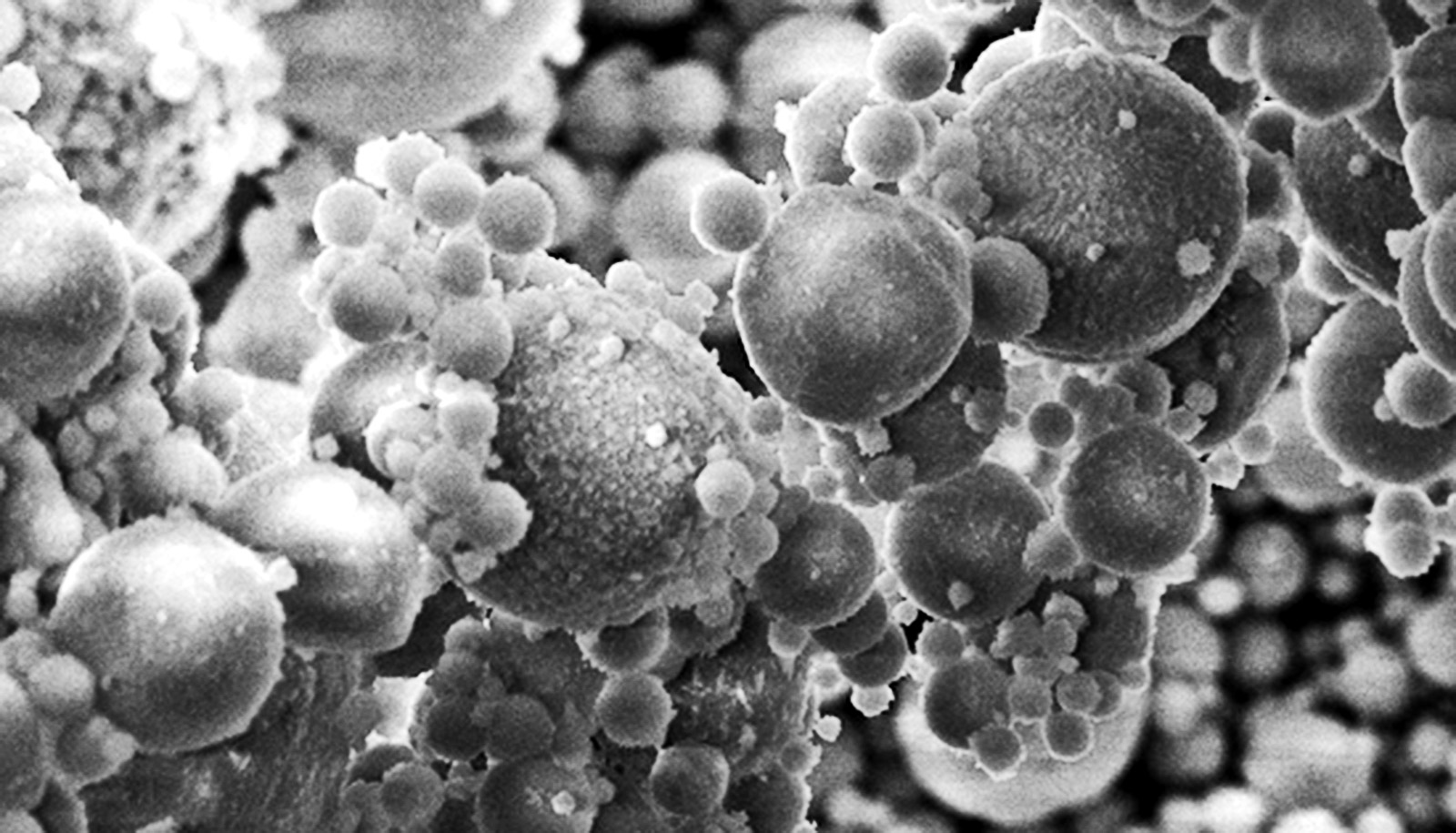

While industrial extraction from these wastes commonly involves leaching with strong acid, a time-consuming, non-green process, the Tour lab heats fly ash and other materials (combined with carbon black to enhance conductivity) to about 3,000 degrees Celsius (5,432 degrees Fahrenheit) in a second. The process turns the waste into highly soluble “activated REE species.”

Tour says treating fly ash by flash Joule heating “breaks the glass that encases these elements and converts REE phosphates to metal oxides that dissolve much more easily.” Industrial processes use a 15-molar concentration of nitric acid to extract the materials; this process uses a much milder 0.1-molar concentration of hydrochloric acid that still yields more product.

In experiments led by postdoctoral researcher and lead author Bing Deng, the researchers found flash Joule heating coal fly ash (CFA) more than doubled the yield of most of the rare earth elements using very mild acid compared to leaching untreated CFA in strong acids.

“The strategy is general for various wastes,” Bing says. “We proved that the REE recovery yields were improved from coal fly ash, bauxite residue, and electronic wastes by the same activation process.”

The generality of the process makes it especially promising, Bing says, as millions of tons of bauxite residue and electronic waste are also produced every year.

“The Department of Energy has determined this is a critical need that has to be resolved,” Tour says. “Our process tells the country that we’re no longer dependent on environmentally detrimental mining or foreign sources for rare earth elements.”

Tour’s lab introduced flash Joule heating in 2020 to convert coal, petroleum coke, and trash into graphene, the single-atom-thick form of carbon, a process now being commercialized. The lab has since adapted the process to convert plastic waste into graphene and to extract precious metals from electronic waste.

Tour is chair in chemistry as well as a professor of computer science and of materials science and nanoengineering.

The Air Force Office of Scientific Research and the Department of Energy supported the research.

Source: Rice University