An automated way to produce polymers makes it much easier to create advanced materials aimed at improving human health, researchers report.

The work is a critical step in pushing the limits for researchers who want to explore large libraries of polymers, including plastics and fibers, for chemical and biological applications such as drugs and regenerative medicine through tissue engineering.

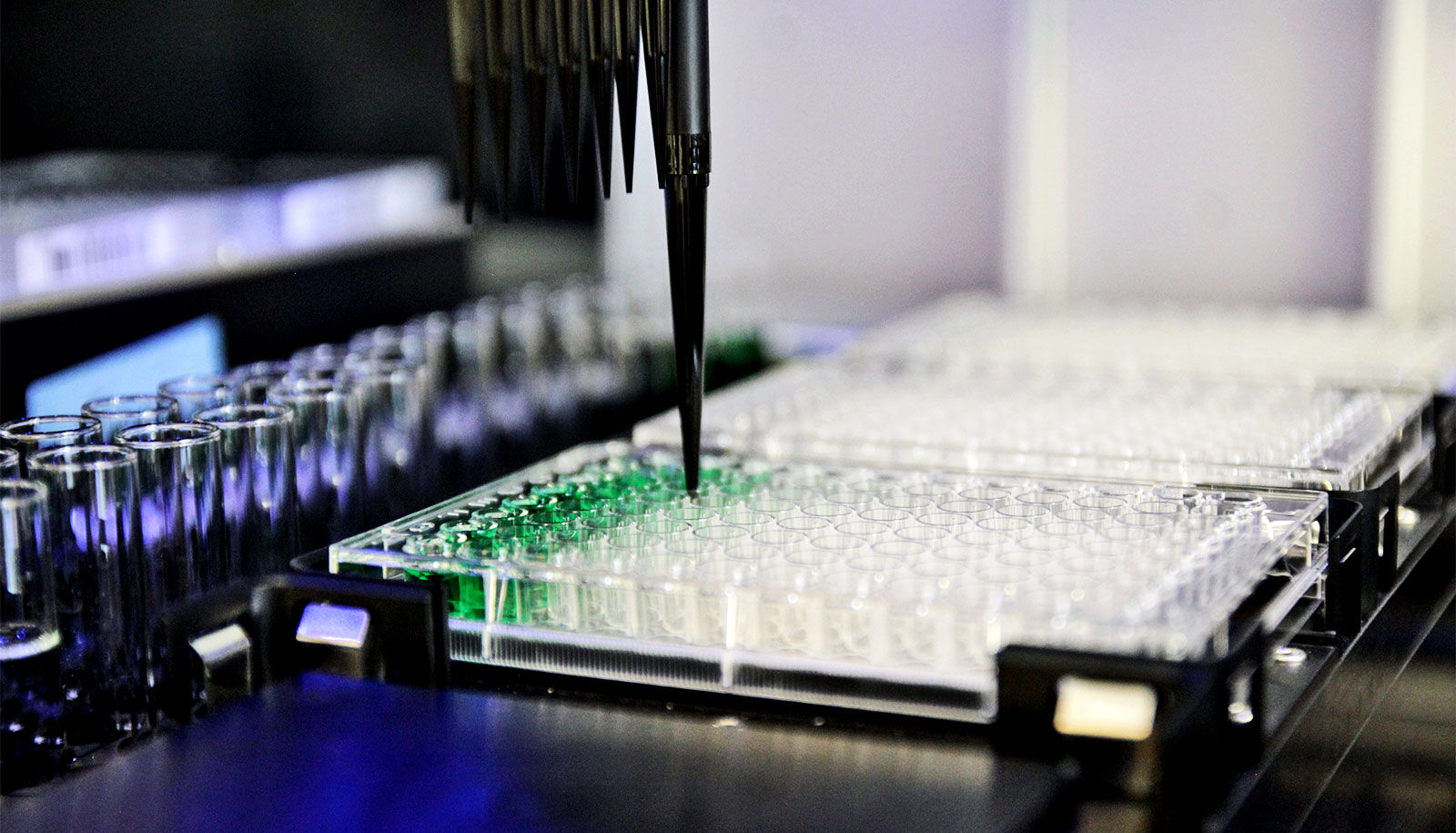

While a human researcher may be able to make a few polymers a day, the new automated system—featuring custom software and a liquid-handling robot—can create up to 384 different polymers at once, a huge increase over current methods.

Synthetic polymers are widely used in advanced materials with special properties, and their continued development is crucial to new technologies, according to the study in the journal Advanced Intelligent Systems. Such technologies include diagnostics, medical devices, electronics, sensors, robots, and lighting.

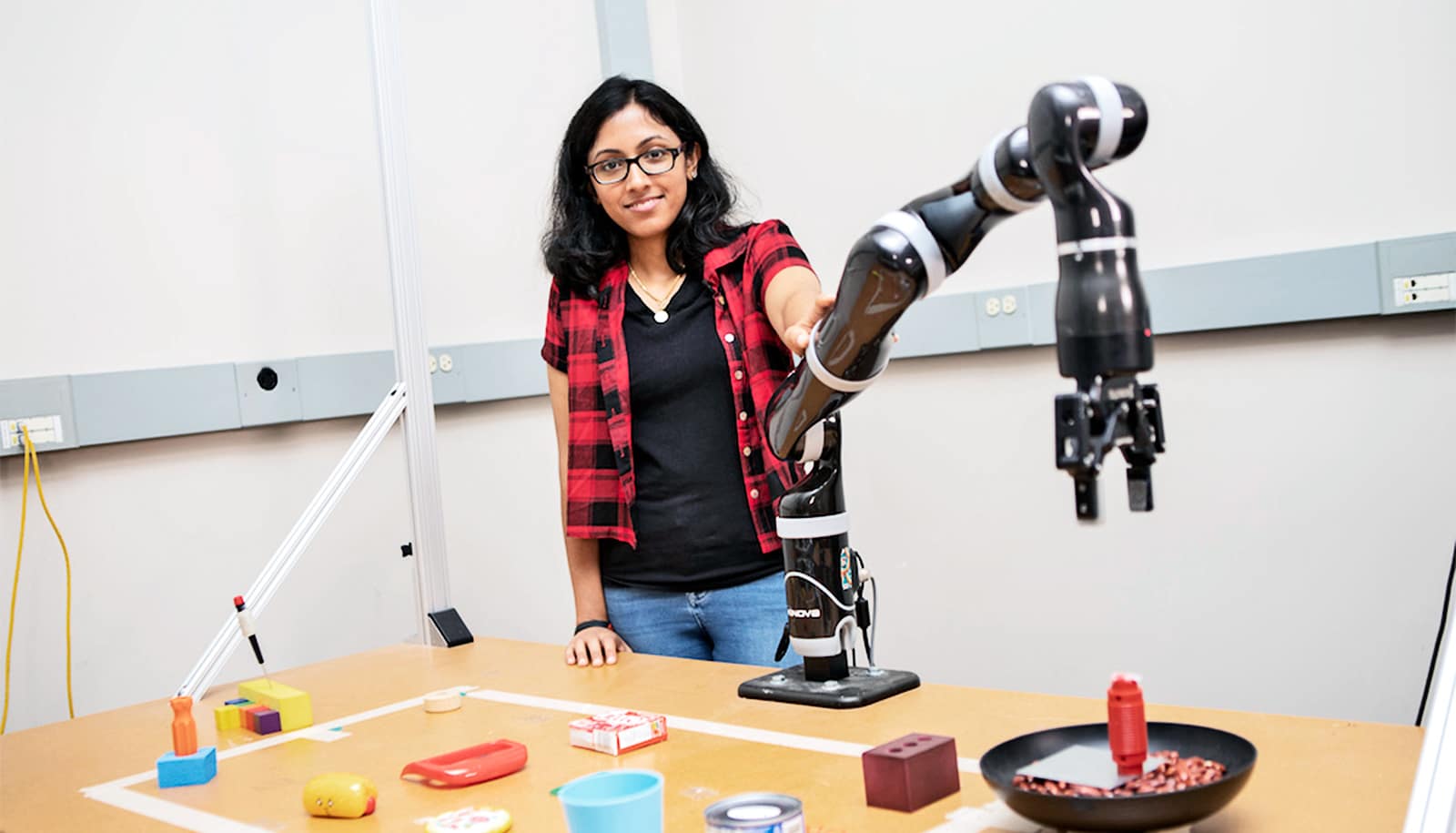

“Typically, researchers synthesize polymers in highly controlled environments, limiting the development of large libraries of complex materials,” says senior author Adam J. Gormley, an assistant professor in the biomedical engineering department in the School of Engineering at Rutgers University–New Brunswick. “By automating polymer synthesis and using a robotic platform, it is now possible to rapidly create a multitude of unique materials.”

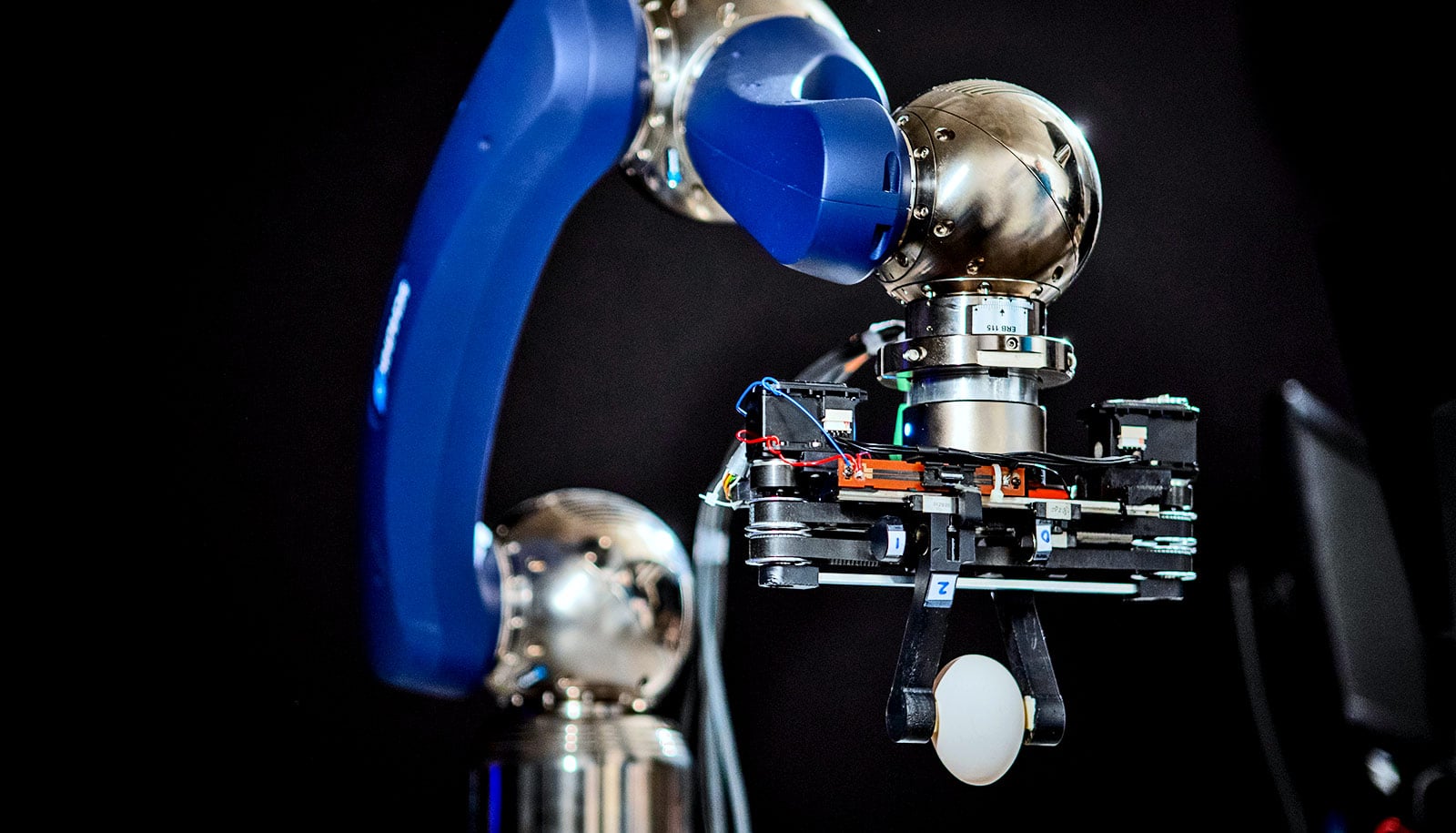

Robotics has automated many ways to make materials as well as discover and develop drugs. But synthesizing polymers remains challenging because most chemical reactions are extremely sensitive to oxygen and can’t be done without removing it during production. The Gormley lab’s open-air robotics platform carries out polymer synthesis reactions that tolerate oxygen.

The group developed custom software that allows a liquid handling robot to interpret polymer designs made on a computer and carry out every step of the chemical reaction. One benefit: the new automated system makes it easier for non-experts to create polymers.

Additional researchers at Rutgers and the Australian Centre for Nanomedicine and Centre for Advanced Macromolecular Design also contributed to the study. Funding for the work came from the New Jersey Health Foundation.

Source: Rutgers University