By patterning nanoscale donuts into a 2D crystal, researchers have achieved a new level of control over its electrical and optical properties.

As researchers eye nanoscale materials for applications like quantum information processing, a method to tailor them from the bottom up will make them more practical.

The research team reports its results in Science Advances.

Scientists at Oak Ridge National Laboratory first grew 2D tungsten disulfide via chemical vapor deposition on a flat substrate patterned with sharp steps and trenches and curved in only one direction. The crystal easily conformed to the obstacles without any change to its properties.

But when they made the supporting surface a dome or a well—in scientific terms, a “non-zero” Gaussian curvature—the growing crystal had to adjust by stretching or contracting. An outward curve added tensile strain and shrank its electrical bandgap to change its semiconducting properties. An inward curve added compressive strain, making it a stronger insulator.

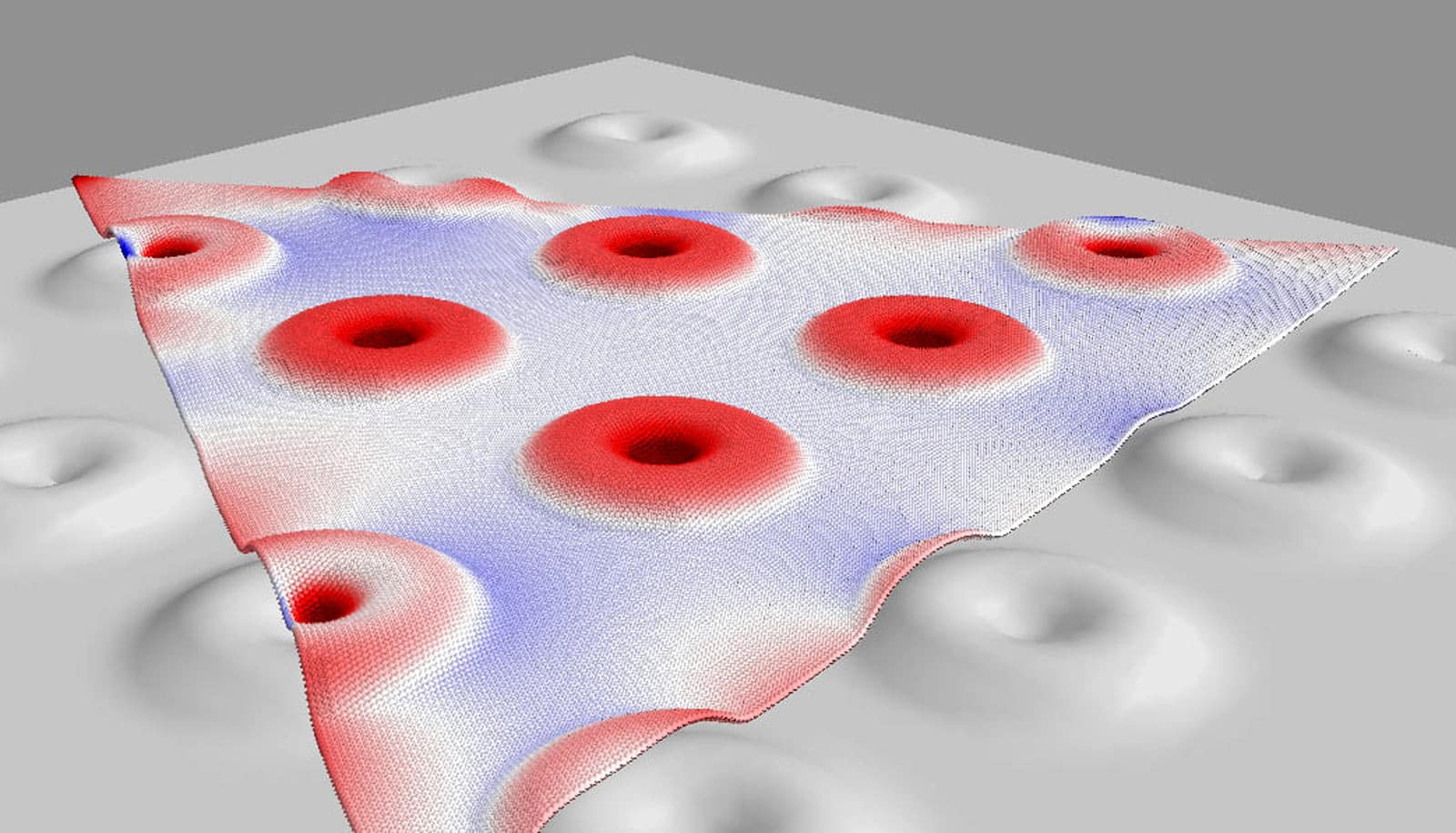

That inspired the donuts. Micron-scale rings between 20 and 180 nanometers high, imprinted into the substrate, forced the crystal to conform to the rising and falling curves, compressing it on the outer slope of each donut and stretching it in the hole.

“As the material grows over the topography of a donut, it creates localized strain,” says Nitant Gupta, a graduate student at Rice University. “Strain in 2D material is beneficial because it allows us to tune its electronic properties, so we can change the bandgap at different places.”

The Rice team’s mathematical models showed most of the strain (and the bandgap change) occurred at the donuts’ centers, less on the body and least outside, as confirmed by photoluminescent and Raman spectra measurements by Oak Ridge.

Oak Ridge scientist Kai Xiao says highly localized strain is one way to make arrays of “hot spots” for single-photon emitters, a component of quantum computers. “You can engineer how much strain you impart to a crystal by designing objects for them to grow over,” he says.

The researchers discovered the height of the donuts affected the strain within and without, and even influenced the crystal’s growth pattern. They found 40-nanometer donuts appeared to be the sweet spot for maximum strain in the hole. Above that, strain spread beyond the bumps and changed the crystal’s normal triangular growth pattern, causing the material to branch out.

Growth over 180-nanometer donuts led to multiple merging crystals separated by grain boundaries. High curvature of the substrate broke the crystals into separate domains, suggesting a future method to control those boundaries and their electronic properties.

Strain also influenced phonons, the collective vibrational excitations in material that affect the conduction of heat, electricity, and sound. Tensile strain softened phonon modes, while compressive strain stiffened them.

Surprisingly, the crystals grew faster in the flat plains between donuts. Oak Ridge models showed the strain prompted additional nucleation sites between the obstacles. And when the crystals were removed from the substrate, the strain disappeared and no trace of the trench or donut patterns remained.

Rice graduate student Henry Yu says the new work continues a collaboration that started with patterning 2D materials onto cones. “In that paper we mainly explored how topography like a cone can create grain boundaries, essentially breaking the material up into two pieces,” he says. “Here, we’re mostly focusing on how the strain changes the bandgap or the properties, and how to avoid breaking up.”

Ideally, says Rice materials theorist Boris Yakobson, the work will lead to computational models that allow researchers to predict the characteristics of any 2D material on any kind of supporting surface. “An even greater challenge is to solve the inverse problem—that is, to determine the topography of the substrate, which would yield the specific pattern of strain desired for electronic, optical, or magnetic functionality of the deposited atomic film,” he says.

Coauthors of the paper are from Oak Ridge; Nanjing University of Aeronautics and Astronautics, China; and the University of Tennessee.

The US Department of Energy Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division; the DOE’s Center for Nanophase Materials Sciences; DOE’s National Energy Research Scientific Computing Center, and the Office of Naval Research supported the research.

Source: Rice University