A new nanofiber solution creates thin, see-through air filters that offer airflow 2.5 times better than that of conventional air filters.

The researchers engineered organic molecules from phthalocyanine, a chemical compound commonly used in dyeing, which can self-organize to form nanoparticles and then nanofibers.

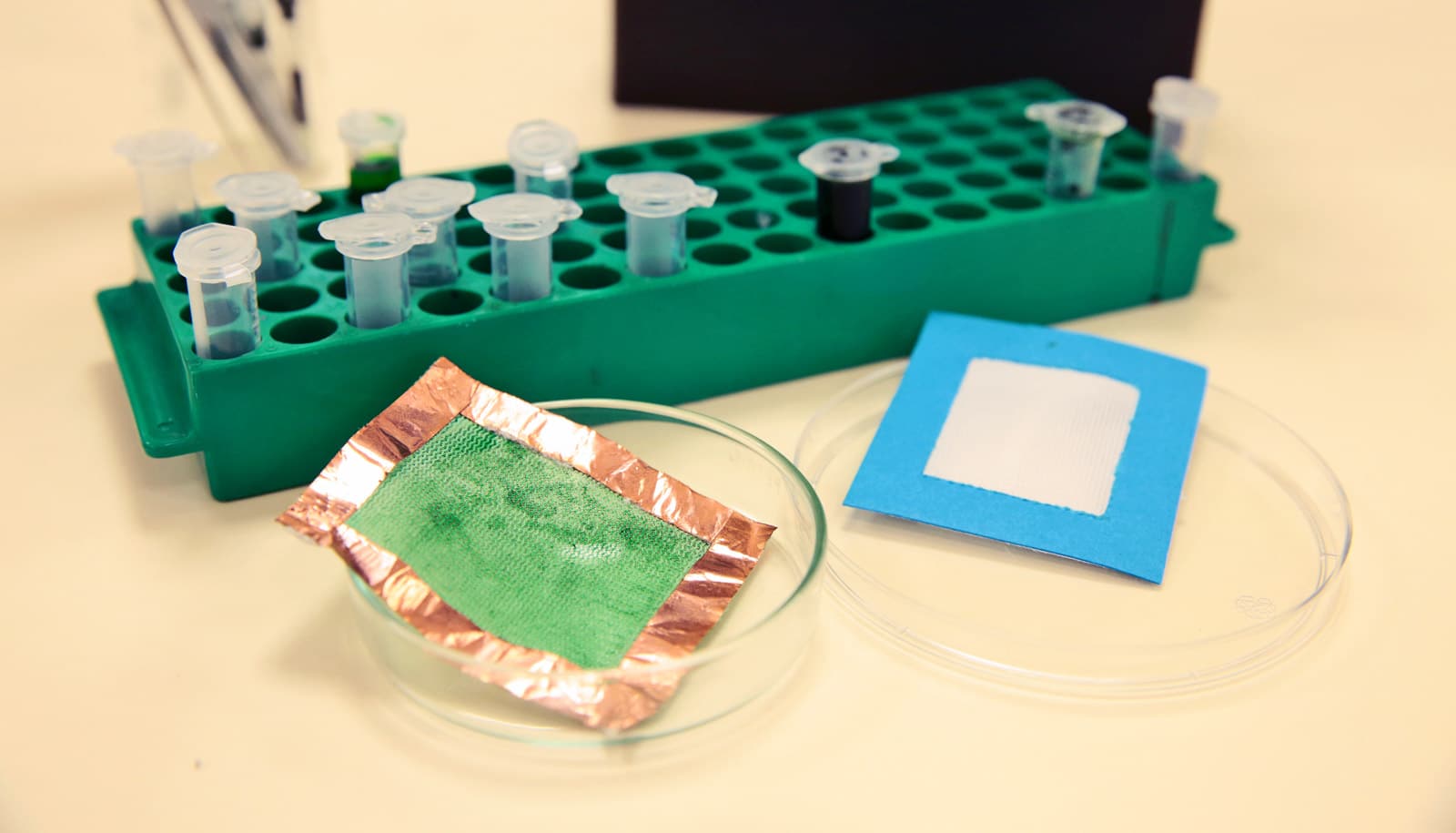

The nanofibers are suspended in liquid and easily “cling” onto non-woven mesh. Spreading the concoction onto non-woven mesh and leaving it to dry naturally produces improved air filters.

Most of the current nanofibers used in air filters are energy intensive to produce and require specialized equipment, according to team leader Tan Swee Ching from National University of Singapore Materials Science and Engineering.

“Our team has developed a simple, quick and cost-effective way of producing high-quality air filters that effectively remove harmful particles and further improves indoor air quality by enhancing air ventilation and reducing harmful UV rays,” he says. He adds that it may be possible in the future to buy the nanofiber solution and create DIY air filters at home.

Air pollution poses serious health threats. Even limited exposure to air pollutants can trigger respiratory symptoms and aggravate existing heart or lung conditions. Even healthy people can suffer from irritation of the eyes, nose, and throat.

Air pollution makes bees bumbles search for food

The new air filter offers a quality factor of about two times higher than commercial respirators. It can filter up to 90 percent of hazardous particles that are less than 2.5 microns in size—also known as PM2.5 particles.

Tan says that high-efficiency air filters often require multiple layers of microfibers or nanofibers, thus limiting their transparency and as such, are not suitable for incorporation in doors and windows.

“The see-through air filter developed using our approach has promising applications in terms of improving indoor air quality, and could be especially useful for countries experiencing haze or with high pollution levels. While increasing filtration efficiency will lead to a trade-off in airflow, the overall performance of our air filter is still better than commercial respirators,” he explains.

The research team has filed a patent for their invention, and plans to include further functionalities, such as antibacterial properties, into the air filter. They plan to work with industry partners to commercialize the technology as well. Their work appears in the journal Small.

Source: National University of Singapore