Rigidity and elasticity are usually at opposite ends of the continuum. You can have one, but not the other. Now, scientists have taken a step closer to a material that has both.

Typically, the more elastic a material, the less able it is to bear loads and resist forces. The more rigid it is, the more prone it is to rupture at lower strains when the load or force exceeds its capacity.

“You can see both rigidity and extensibility with mussels’ byssus threads,” says co-lead author Kayetan Chorazewicz.

Mussels spend their lives in the rocky intertidal zone, where their ability to hold fast is a matter of life and death. The threads they exude onto the rocks must be both stretchable enough to allow them to find the appropriate “grip” on irregular surfaces and absorb the constant pounding of waves, yet rigid enough to keep the mussels themselves from bouncing around in the currents and banging against the structures to which they’ve affixed themselves.

Sticky secret

The optimal combination of the two qualities is among the secrets of their success in such a variable and inhospitable environment.

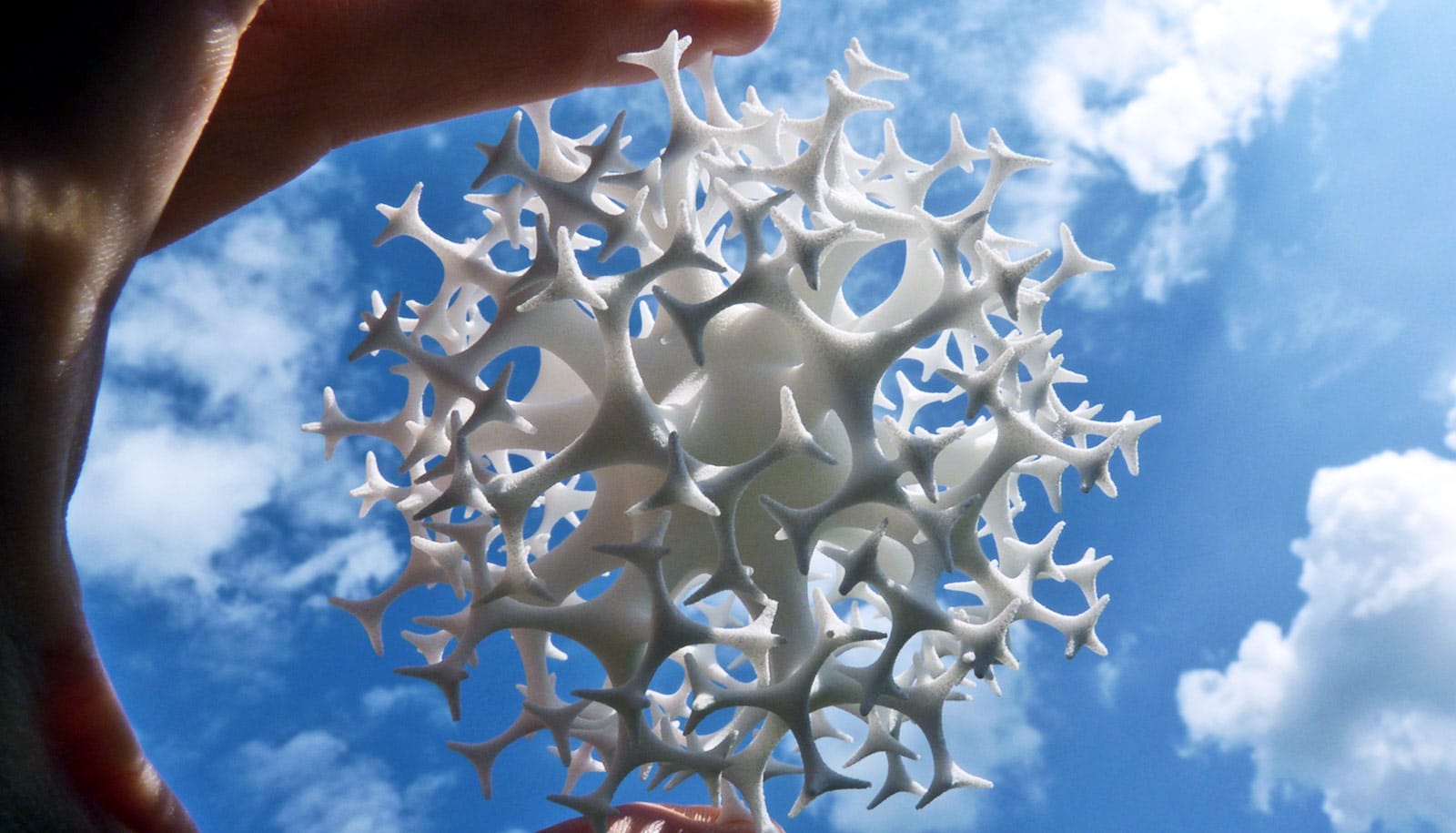

Taking their cue from mollusks, researchers designed a functionally graded material—a relatively new class of materials that takes advantage of differences in their compositions—to create a synthetic version of the mussels’ byssus threads that not only minimizes the trade-off between flexibility and strength, but also can be used in wet environments.

As reported in Macromolecular Chemistry and Physics, the key to this technology is a cross-linked combination of the monomer benzyl acrylate (BZA) with triethylene glycol dimethacrylate (TEGDMA), a common polymer used in dental restoration fillers.

Cross-linking, as opposed to creating a “sandwich” of individual layers of BZA or TEGDMA, gives the resulting material abilities that neither of them alone would have, the researchers say: the ability to withstand strain at a wide range of temperatures, and the ability to bear loads.

Researchers can further tune the copolymer combination such that its layers would have varying levels of elasticity in the same way that byssus threads exhibit a gradient of elasticity that changes from its soft collagen fiber core to its hard exterior cuticle. In this way, the material can either effectively absorb effectively stresses or resist them outright.

“It can also prevent any fractures from propagating throughout the material,” says co-lead author Sameer Sundrani.

New class of materials

Should there be excessive stress, the strain energy would be redirected and confined and some of the material could be sacrificed in a “beneficial delamination” that would avoid failure of the entire structure.

The technology has a wide array of applications, the researchers say.

“These days, more and more materials are being replaced by engineered polymers,” says the paper’s senior, corresponding author Kollbe Ahn, a materials scientist at the University of California, Santa Barbara’s Marine Science Institute.who has worked extensively with mussel-inspired biomimetic polymers.

“We can imagine any polymer-based material that requires load-bearing,” including tougher plastics, protection gear such as helmets, construction parts, and more durable aircraft, vehicle, and watercraft components.

Further, the fields of medicine, bioengineering, bioelectronics, and even soft robotics could benefit from such functionally graded materials, which could be used to make prosthetics, artificial joints, and organs, or soft actuators and machines.

“Another widely practical application would be to apply graded materials like ours to coatings over already existing materials rather than replacing them entirely, for example, stiff plastics or even biomedical implants,” Sundrani says.

“What our functionally graded materials suggest,” notes Chorazewicz, “is a new class of materials to fulfill a wide variety of these roles rather than a specific niche—and since these materials are tunable, they can be as hard or soft as necessary for their intended use.”

The paper is the result of a collaboration inspired by UCSB’s Research Mentorship Program (RMP), a summer session program that pairs high school juniors and seniors with university researchers to conduct original research. At the time they initiated this research, both Chorazewicz and Sundrani were high school seniors.

Source: UC Santa Barbara