A new MRI-based technique quickly diagnoses what ails certain types of batteries—from determining how much charge remains to detecting internal defects—without opening them up.

“The use of alternative energy and electrically powered vehicles will further increase the demand for better and safer batteries,” says Alexej Jerschow, a professor in New York University’s chemistry department.

“However, there are currently only a very limited set of tools available to diagnose a battery’s health without destroying the battery—our non-invasive technique offers a faster and more expansive method for making these assessments.”

“Ensuring cell quality and safety is paramount to the manufacturing process that can save companies significant cost and prevent catastrophic cell failures from occurring,” says Matthew Ganter, co-director of the Battery Prototyping Center at Rochester Institute of Technology.

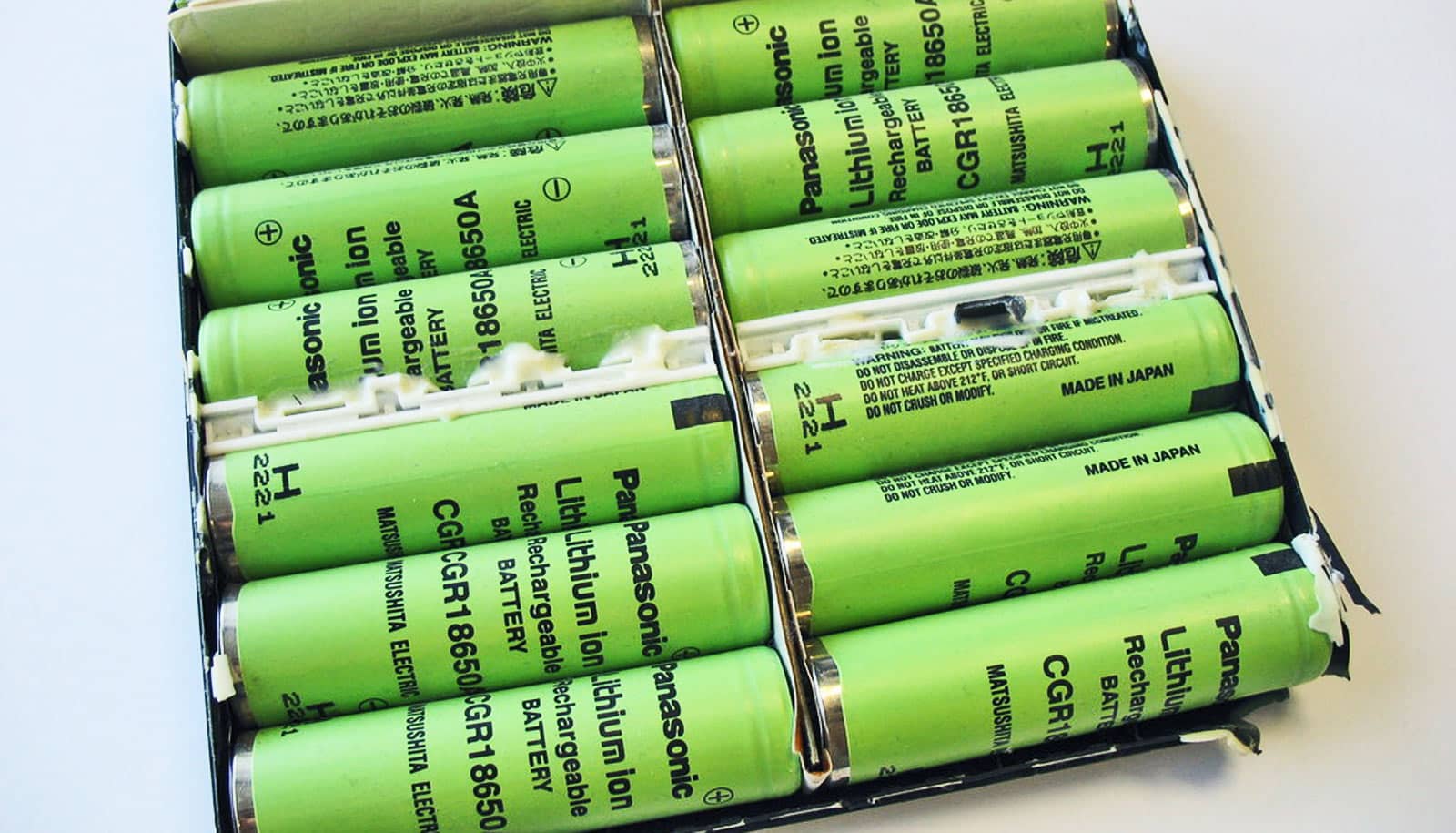

The research focuses on rechargeable lithium-ion (Li-ion) batteries, which are used in cell phones, laptops, and other electronics. Notably, rechargeable batteries are at the heart of new technologies, including electric cars or storage for renewable energy sources.

However, recent malfunctions in hand-held devices and electric vehicles have highlighted the difficulties in designing batteries for them. Further, engineers often can’t determine the nature of defects or even impending battery failures without taking apart the device, which typically results in its destruction.

In general, magnetic resonance (MR) methods provide the ability to measure tiny changes in magnetic field maps and, as a result, create a picture of what lies inside a structure—for example, MRI can produce images of the human body’s organs in a non-invasive manner.

As reported in Nature Communications, the scientists adopted a procedure similar to MRI. Here, they measured tiny magnetic field changes surrounding the battery’s electrochemical cells.

This cell phone doesn’t need any batteries

In their experiments, they examined Li-ion batteries in different states—various levels of charge (i.e., battery life) and conditions (i.e., some damaged and others not).

With cells prepared at RIT’s Battery Prototyping Center, New York University researchers were able to match magnetic field changes surrounding the batteries to different internal conditions, revealing state of charge and certain defects. These included bent and missing electrodes and small foreign objects in the cell, which are flaws that can occur during the normal manufacturing process.

Laser could charge your phone from across the room

“With future enhancements to this method, it could provide a powerful means of predicting battery failures and battery lifetimes as well as facilitate the development of next-generation high-performance, high-capacity, and long-lasting or fast-charging batteries,” Jerschow says.

Other researchers from NYU, RIT, and Brisol-Myers Squibb contributed to the study. The National Science Foundation and NYU’s Technology Acceleration and Commercialization award funded the work.

Source: New York University