A new software system can translate a wide variety of 3D shapes into stitch-by-stitch instructions that allow a computer-controlled knitting machine to automatically produce those shapes.

“Knitting machines could become as easy to use as 3D printers.”

The ability to generate knitting instructions without human expertise could make on-demand machine knitting possible, computer scientists say.

The developers’ vision is to use the same machines that routinely crank out thousands of knitted hats, gloves, and other apparel to produce customized pieces one at a time or in small quantities. Gloves, for instance, might be designed to precisely fit a customer’s hands. Athletic shoe uppers, sweaters, and hats might have unique color patterns or ornamentation.

“Knitting machines could become as easy to use as 3D printers,” says James McCann, assistant professor in the Robotics Institute at Carnegie Mellon University and leader of its Textiles Lab.

That’s in stark contrast to the world of knitting today.

“Now, if you run a floor of knitting machines, you also have a department of engineers,” says McCann, who noted that garment designers rarely have the specialized expertise necessary to program the machines. “It’s not a sustainable way of doing one-off customized pieces.”

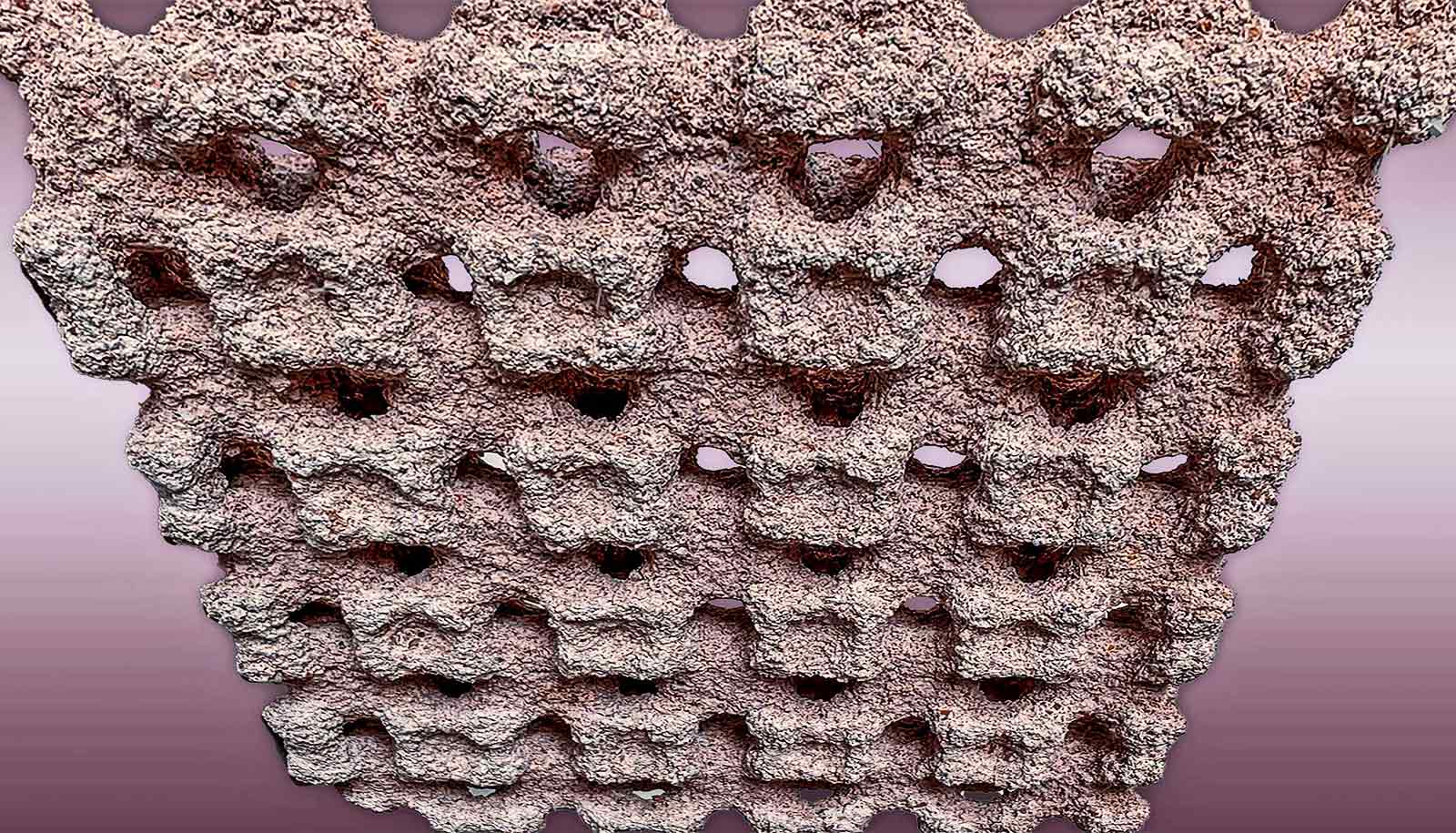

McCann and colleagues developed a method for transforming 3D meshes—a common method for modeling 3D shapes—into instructions for V-bed knitting machines.

The widely used machines manipulate loops of yarn with hook-shaped needles, which lie in parallel needle beds angled toward each other in an inverted V shape. The machines are highly capable, but are limited in comparison with hand knitting, says Vidya Narayanan, a computer science PhD student.

The new algorithm takes these constraints into account, producing instructions for patterns that work within the limits of the machine and reduce the risk of yarn breaks or jams.

A front-end design system such as this is common in 3D printing and in computer-driven machine shops, but not in the knitting world, McCann says.

Likewise, 3D printing and machine shops use common languages and file formats to run their equipment, while knitting machines use a variety of languages and tools that are specific to particular brands of knitting machines.

McCann led an earlier effort to create a common knitting format, called Knitout, which can work with any brand of knitting machine.

This 3D printing method makes a better nose

Further work is needed to make on-demand knitting a reality. For instance, the system now only produces smooth knitted cloth, without the patterned stitching that can make knitted garments distinctive. The knitting ecosystem also needs to be expanded, with design tools that will work with any machine. But progress could speed up at this point, McCann says.

“The knitting hardware is already really good. It’s the software that needs a little push. And software can improve rapidly because we can iterate so much faster.”

McCann and colleagues will present the work this summer at SIGGRAPH 2018, the Conference on Computer Graphics and Interactive Techniques in Vancouver, Canada. Additional collaborators are from Carnegie Mellon and ETH Zurich.

Source: Carnegie Mellon University