Researchers have created a knitted textile that serves as the shaping element for curved concrete shells. They’ve used the new technology to create a five-ton concrete structure for an exhibition in Mexico City.

The heart of the 13-foot tall curved concrete shell is a knitted formwork textile that a steel cable-net supports. The prototype, called KnitCandela, marks the first architectural-scale application of this technology. The structure is an homage to Spanish-Mexican architect Felix Candela (1910–1997).

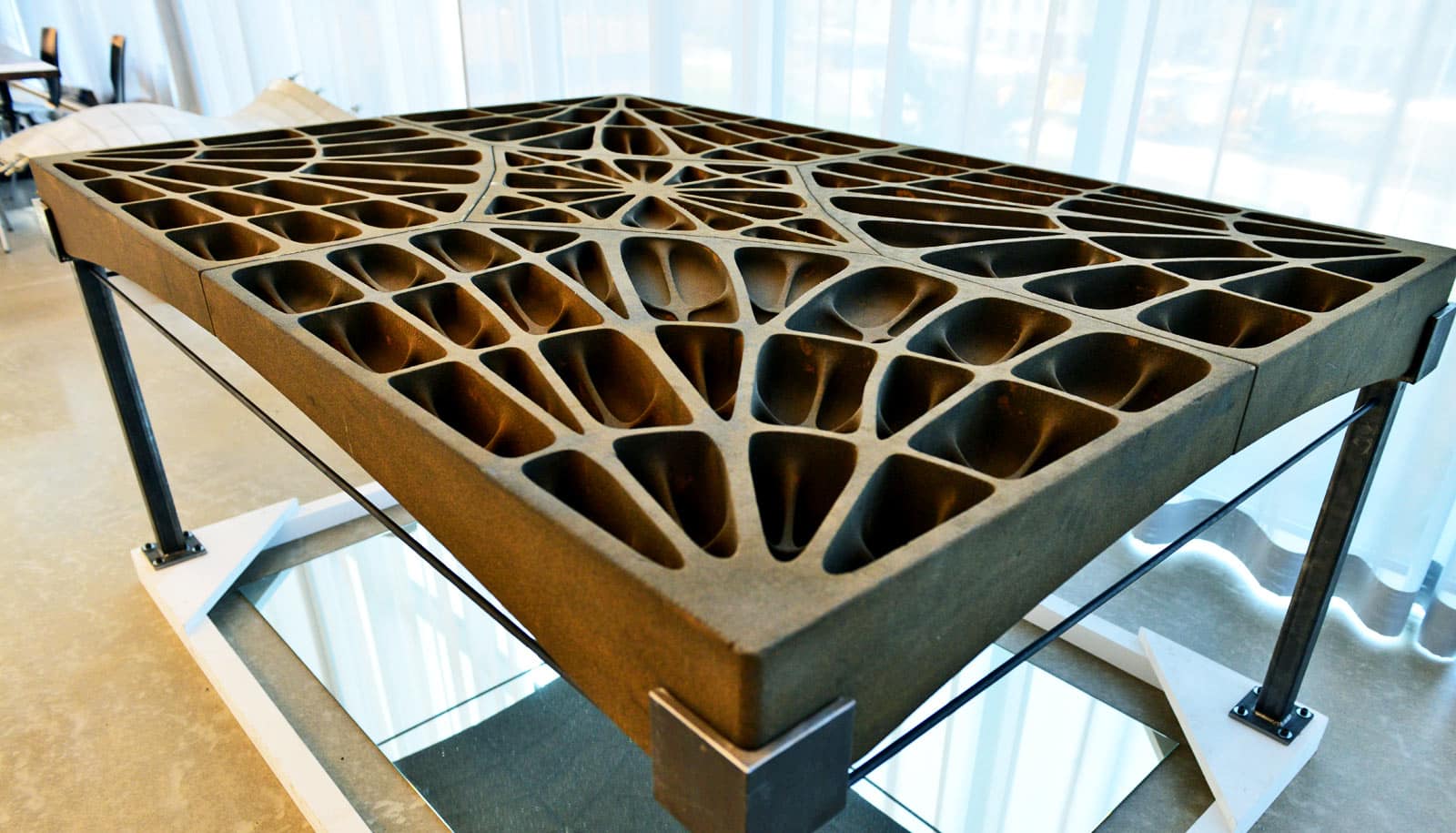

Following a digitally generated pattern, an industrial knitting machine produced the shuttering of the formwork for the shell structure: in 36 hours, it knitted a fully shaped, double-layered 3D textile consisting of four long strips.

The lower layer forms the visible ceiling—a designed surface with a colorful pattern. The upper layer contains sleeves for the cables of the formwork system and pockets for simple balloons, which, after the entire structure is coated in concrete, become hollow spaces that help save on materials and on weight.

Manufacturing a formwork for such a geometrically complex structure using conventional methods would cost substantially more in both time and material.

In the museum’s inner courtyard, researchers had the knitted formwork tensioned between a temporary boundary frame and sprayed with a specially formulated cement mixture. This initial layer was just a fraction of an inch thick, but sufficient to create a rigid mold; once it hardened, a team applied conventional fiber-reinforced concrete.

The researchers brought the knitted fabric to Mexico City inside two suitcases—as normal checked baggage. The knit weighs only 55 pounds (25 kilograms) and the cable net around 66 pounds (30 kilograms). Taut in between the boundary frame, they supported over 5 ton of concrete curves.

Mariana Popescu and Lex Reiter developed the technology behind KnitCandela as part of Switzerland’s National Centre of Competence in Research (NCCR) in Digital Fabrication research project. Mariana Popescu is a doctoral student with Philippe Block, professor of architecture and structure at ETH Zurich, while doctoral student Lex Reiter studies with Robert Flatt, professor of physical chemistry of building materials.

Popescu’s research shows that employing knitted textiles in architectural applications cuts down on material, labor, and waste, and simplifies the construction process for complex shapes.

“It took only five weeks from the initial work until completion—much less time than if we were using conventional technology,” says Matthias Rippmann, project manager for KnitCandela and senior researcher in the Block Research Group.

KnitCandela also represents an evolution of the flexible forming system researchers developed for the HiLo roof: a doubly curved, thin-shell concrete structure the Block Research Group developed for Empa’s research and innovation building NEST in 2017. For KnitCandela, the researchers produced the knitted shell in one go, whereas they created HiLo’s shell with a network of steel cables and a sewn textile.

“Knitting offers a key advantage that we no longer need to create 3D shapes by assembling various parts. With the right knitting pattern, we can produce a flexible formwork for any and all kinds of shell structures, pockets and channels just by pressing a button,” Popescu says.

For the construction industry, 3D printing is a major topic. Philippe Block says that, to a certain extent, his group’s pioneering method is a new form of 3D printing, “only it doesn’t require a completely new kind of machine. A conventional knitting machine will do just fine.”

The researchers collaborated on the project with Zaha Hadid Architects Computation and Design Group (ZHCODE) and Architecture Extrapolated (R-Ex).

Source: Michael Walther for ETH Zurich