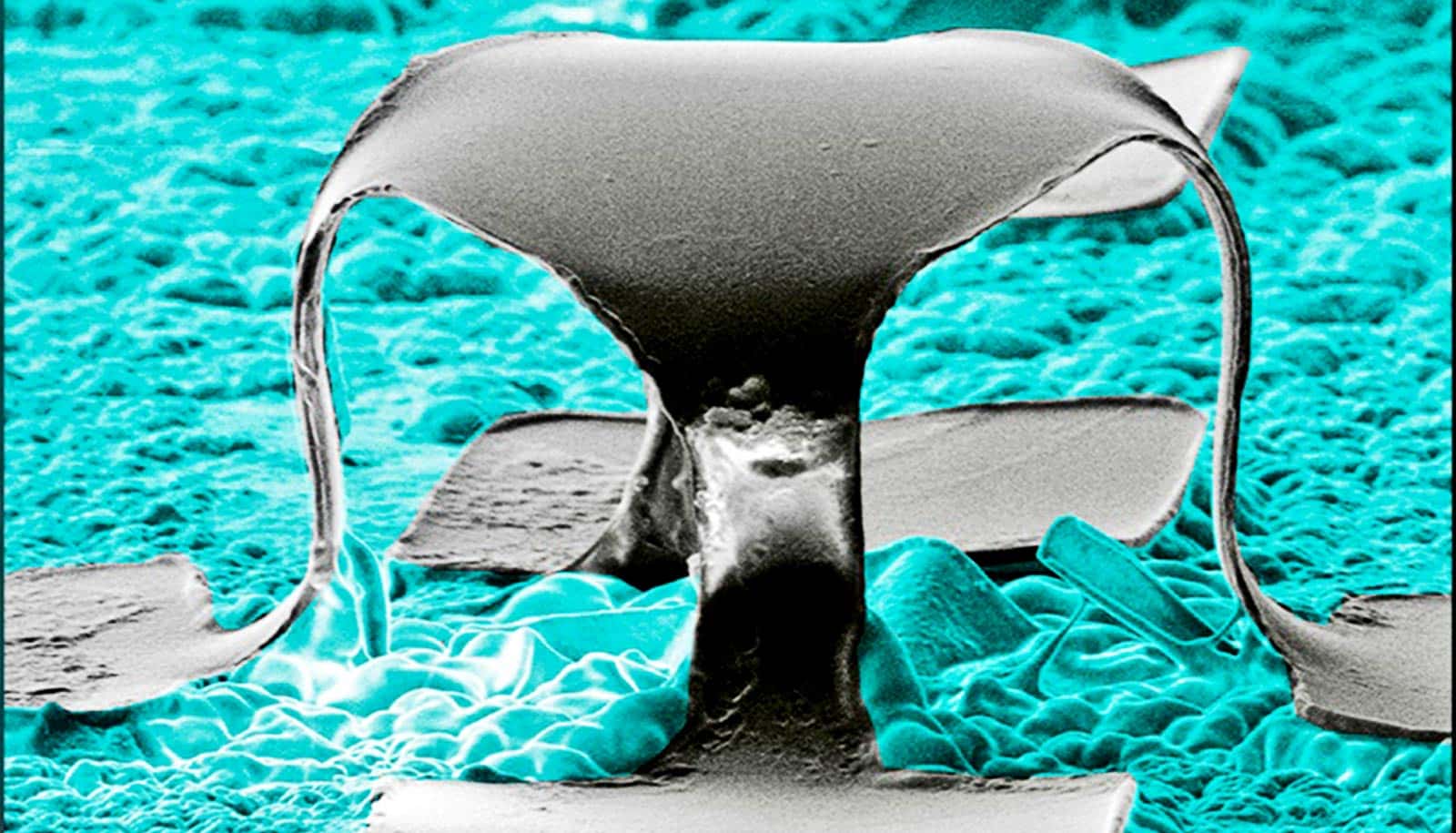

A new approach to making metamaterials draws on kirigami techniques to make 3D, reconfigurable building blocks that can be used to create complex, dynamic structures.

Because the design approach is modular, these structures are easy to both assemble and disassemble.

“Applying kirigami to three-dimensional materials offers a new level of reconfigurability for these structures,” says Jie Yin, an associate professor of mechanical and aerospace engineering at North Carolina State University and corresponding author of the study in Advanced Functional Materials.

Researchers are optimistic that these 3D metamaterials could be used in applications such as lightweight construction materials for buildings, components for modular robotics, and wave guiding in acoustic metamaterials.

Kirigami is a variation of origami that involves cutting paper, in addition to folding it. While kirigami is done using two-dimensional materials, such as paper, Yin and his collaborators have applied the principles of kirigami to three-dimensional materials that are cut into connected cubes.

Specifically, the researchers modeled their new approach using a series of eight connected cardboard cubes that are open on two sides. Think of each unit of eight connected cubes as a building block. Depending on how the cubes are connected to each other, these building blocks can be folded into more than 300,000 different designs.

“Think of these kirigami units as versatile building blocks that can be assembled to create larger structures with different mechanical properties,” Yin says. “What’s more, the larger structures can also be disassembled, allowing users to reassemble the kirigami units into new structures.”

To demonstrate the utility of the concept, the researchers created more than a dozen reconfigurable building blocks. Each block consisted of eight connected paper cubes and could be reconfigured into eight different shapes.

A video highlights the ways that each unit could be reconfigured into different structures, how those structures could be assembled into larger structures, and how the assembled large structures could be disassembled back into the reconfigurable blocks.

Depending on the orientation of the solid cube walls and open sides in each block, and the placement of each block in the larger structure, the structure will behave differently. This allows users to tune each building block’s mechanical properties. For example, a single building block could be folded into a structure that can be easily compressed, or refolded into a different shape that is capable of bearing a significant load.

“The fact that you can disassemble and reconfigure these 3D metamaterials allow users to alter the mechanical properties of a structure as needed to perform different tasks,” Yin says. “Fold it one way to make it easy to compress, fold it another way to allow for lateral movement, fold it a third way to make it rigid or enhance its physical strength—and so on.

“This work was focused on demonstrating the fundamental concept,” Yin says. “Our next step is to demonstrate applications for the concept.”

Additional coauthors are from Yale University and NC State. The National Science Foundation funded the work.

Source: NC State