Three-dimensional materials that borrow from kirigami can create structures capable of transforming into multiple different architectures.

Researchers envision applications ranging from construction to robotics.

“The system we’ve developed was inspired by metamorphosis,” says Jie Yin, corresponding author of a paper on the work and an associate professor of mechanical and aerospace engineering at North Carolina State University. “With metamorphosis in nature, animals change their fundamental shape. We’ve created a class of materials that can be used to create structures that change their fundamental architecture.”

Kirigami is a fundamental concept for Yin’s work. Kirigami is a variation of origami that involves cutting and folding paper. But while kirigami traditionally uses two-dimensional materials, Yin applies the same principles to 3D materials.

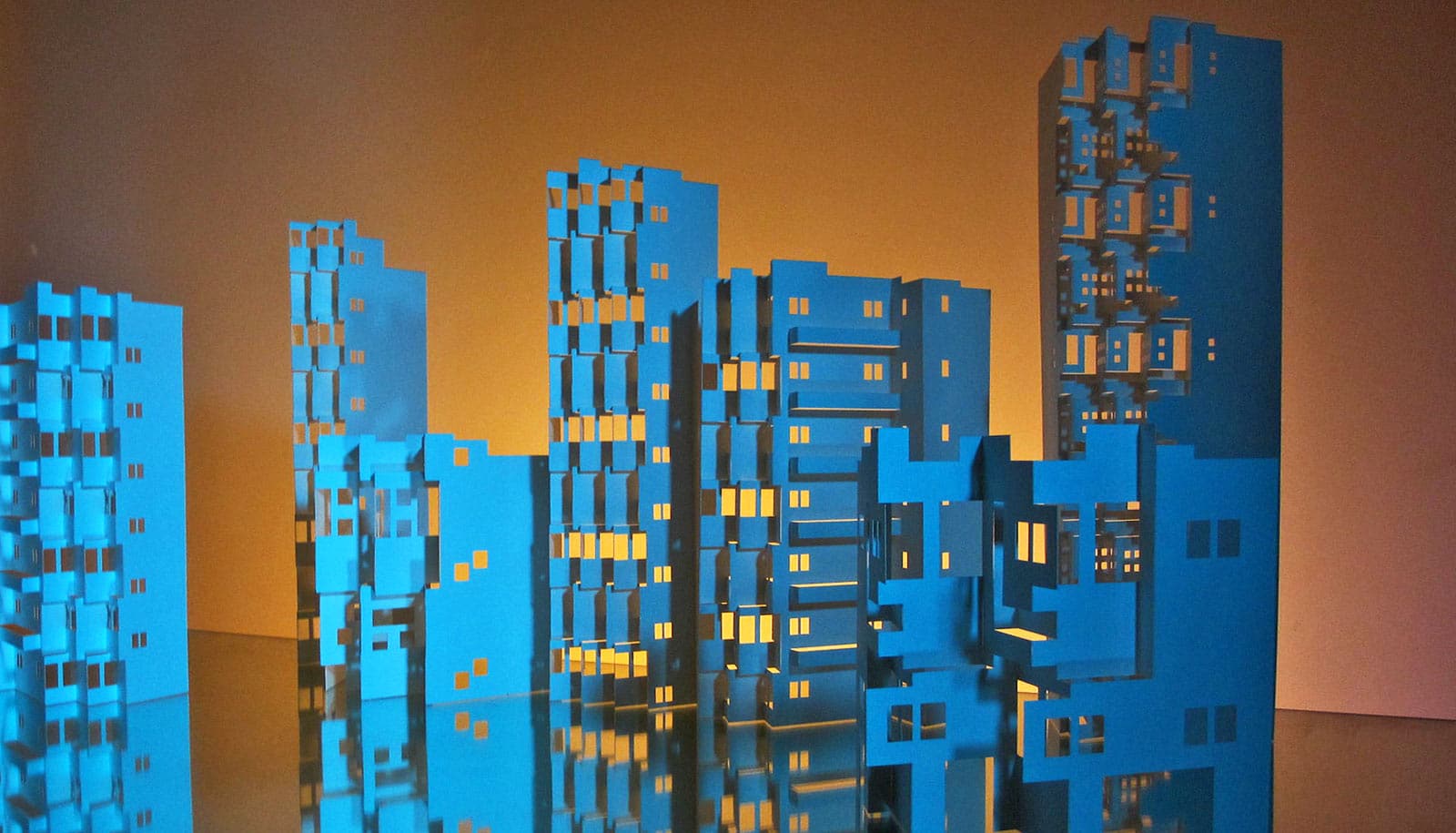

Kirigami material

The metamorphosis system starts with a single unit of 3D kirigami. Each unit can form multiple shapes in itself. But these units are also modular—they can connect to form increasingly complex structures. Because the individual units themselves can form multiple shapes, and can connect to other units in multiple ways, the overall system can form a wide variety of architectures.

“Think of what you can build with conventional materials,” Yin says. “Now imagine what you can build when each basic building block is capable of transforming in multiple ways.”

Yin’s lab previously demonstrated a similar concept, in which 3D kirigami units were stacked on each other. In that system, the units could be used to assemble a structure—but the structure could also then be disassembled.

The metamorphosis system involves actually connecting the kirigami units. In other words, once the units are connected to each other they cannot be disconnected. However, the larger structures they create are capable of transforming into multiple, different architectures.

“There are two big differences between our first kirigami system and the metamorphosis system,” Yin explains.

“The first kirigami system involved units that could be assembled into architectures and then disassembled, which is an advantage. However, when the units were assembled, the architecture wouldn’t be capable of transforming. Because the sides of the unit were not rigid and fixed at 90-degree angles, the assembled structure could bend and move—but it could not fundamentally change its geometry.

“The metamorphosis kirigami system does not allow you to disassemble a structure,” Yin says. “And because the sides of each cubic unit are rigid and fixed at 90-degree angles, the assembled structure does not bend or flex very much. However, the finished structure is capable of transforming into different architectures.”

Structural integrity

In proof-of-concept testing, the researchers demonstrated that the metamorphosis system was capable of creating many different structures that can bear significant weight while maintaining their structural integrity.

That structural integrity is important, because Yin thinks construction is one potential application for the metamorphosis system.

“If you scale this approach up, it could be the basis for a new generation of construction materials that can be used to create rapidly deployable structures,” Yin says. “Think of the medical units that have had to be expanded on short notice during the pandemic, or the need for emergency housing shelters in the wake of a disaster.”

The researchers also think the metamorphosis system could create a variety of robotic devices that can transform in order to respond to external stimuli or to perform different functions.

“We also think this system could be used to create a new line of toys—particularly toys that can help people explore some fundamental STEM concepts related to physics and engineering,” Yin says. “We’re open to working with industry collaborators to pursue these and other potential applications for the system.”

The paper appears in the journal Materials Today Physics. The work took place with support from the National Science Foundation.

Source: NC State