It’s easy and economical to make shiny pellets of graphite from functionalized graphene, according to new research.

Researchers can press chemically altered graphene powder into a lightweight, semiporous solid that retains many of the strong and conductive qualities of graphite, the form of carbon found in pencils, lubricants, and other products that normally require high-temperature processing.

Mohamad Kabbani, a former graduate student of Rice University materials scientist Pulickel Ajayan and lead author of the paper describing the process, demonstrated that the environmentally friendly, scalable process can be done in minutes by hand by grinding chemically modified graphene into a powder and using a hand-powered press to squeeze the powder into a solid pellet.

Kabbani previously showed how researchers could turn carbon nanotubes into graphene with a mortar and pestle rather than harsh chemicals. This time, he and his colleagues demonstrated how to make a battery-sized pellet, but they can press the graphene powders with chemical functionalities attached to it into any form.

The material could be suitable for structural, catalytic, electrochemical, and electronic applications, Kabbani says.

“This is the first time anyone’s made these at room temperature and without very high pressure,” Kabbani explains. “Usually these kind of materials require sintering (a process that uses pressure or heat to form solids without melting them) at temperatures above 1,000 degrees Celsius to produce strong pellets. In this case, mechano-chemistry at the nanoscale saved us a lot of energy and money.”

The process began with two sets of functionalized nanotubes, one with carboxylic acid and the other with hydroxyl molecules. Once crushed to combine them either by hand or machine, researchers place them in a lab-scale hydraulic press and subject them to 5 tons of pressure.

The functional groups cross-linked the graphene sheets to each other, and even though the researchers used no liquids, the sheets produced a tiny amount of water as a byproduct of the reaction, Kabbani says.

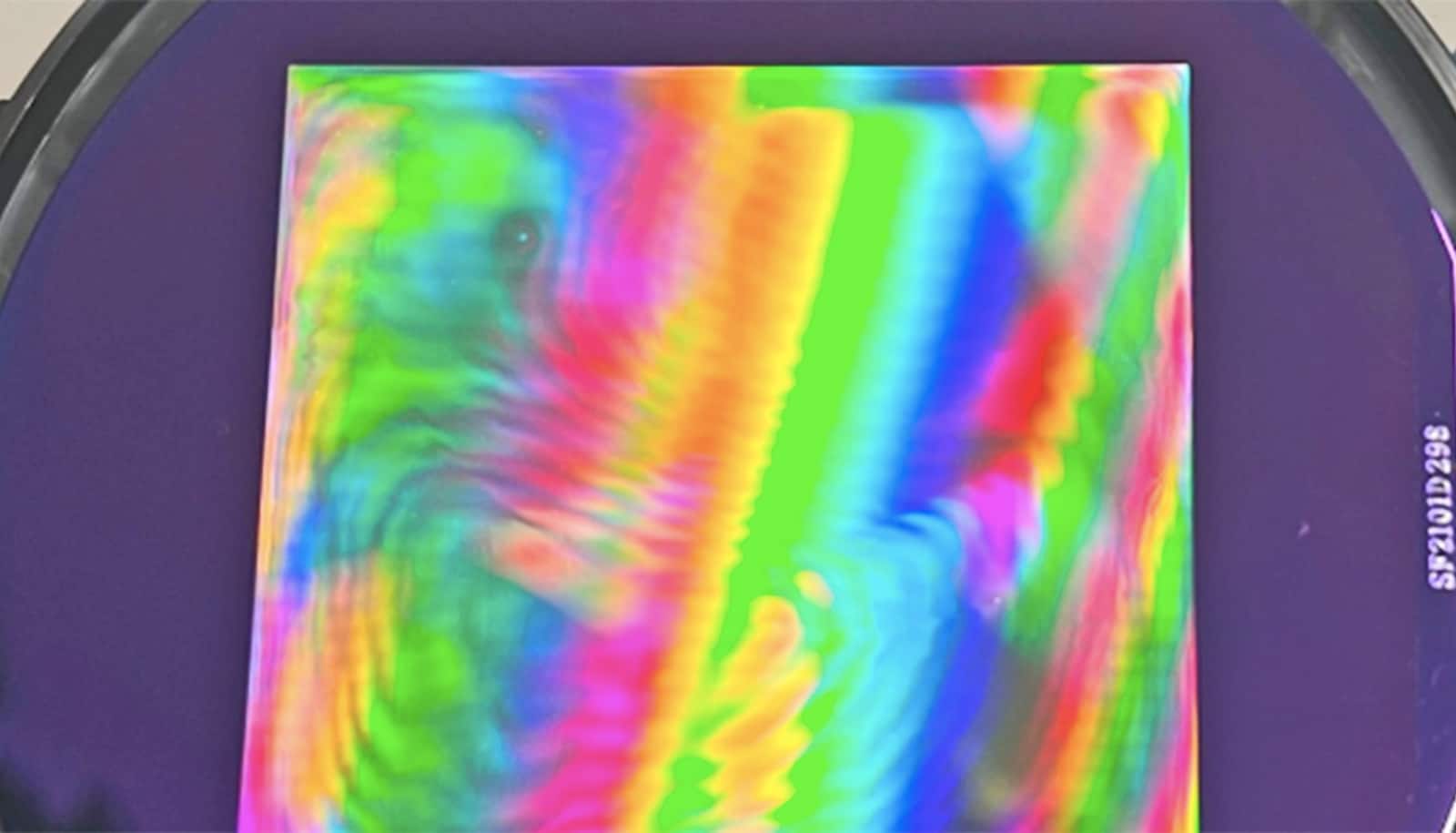

The pellets remained stable when researchers placed them in hot water for five hours, even when they stirred them. This confirmed the interlocking of the graphene sheets within, the researchers report.

Scientists get a good look at electrons inside graphene

The combination of light weight, high strength, and high conductivity is appealing for applications such as conducting cables and electrodes, Kabbani says. “The pellet material is stronger and lighter than commercial graphite electrodes and could be promising for electrical storage applications with high energy and power densities.”

The researchers report their findings in the journal Carbon.

Additional coauthors are from Rice; IIT Gandhinagar, India; Bruker Nano Surfaces, Minneapolis; the Indian Institute of Technology, Madras, India; and the Lebanese American University, Beirut.

Support for the research came from the Department of Defense; the Air Force Office of Scientific Research; the Government of India Nano Mission; and the state of Nuevo Leon, Mexico.

Source: Rice University