A new study reveals a two-step mechanism behind silver’s dissipation from gold-silver nanoparticles.

The discovery could help fine-tune nanoparticle alloys for specific uses.

Gold-silver alloys are useful catalysts that degrade environmental pollutants, facilitate the production of plastics and chemicals, and kill bacteria on surfaces, among other applications. In nanoparticle form, these alloys could be useful as optical sensors or to catalyze hydrogen evolution reactions.

The team, from Rice University and the University of Duisburg-Essen in Germany, employed sophisticated microscopy to show how gold might retain enough silver to stabilize the nanoparticle. Their study appears in the journal ACS Nano.

The researchers used a hyperspectral dark-field imaging microscope to study gold-silver alloy nanoparticles containing an excess of silver in an acidic solution. The technique allowed them to trigger plasmons, ripples of energy that flow across the surface of particles when lit. These plasmons scatter light that changes with the alloy’s composition.

“The dependence of the plasmon on alloy composition allowed us to record silver ion leaching kinetics in real time,” says Alexander Al-Zubeidi, lead author of the study and graduate student at the University of Duisburg-Essen.

Al-Zubeidi notes that films of gold and silver alloy have been in use for decades, often as antibacterial coatings, because silver ions are toxic to bacteria. “I think the silver release mechanism has been implied from studies of alloy films, but it’s never been proven in a quantitative way,” he says.

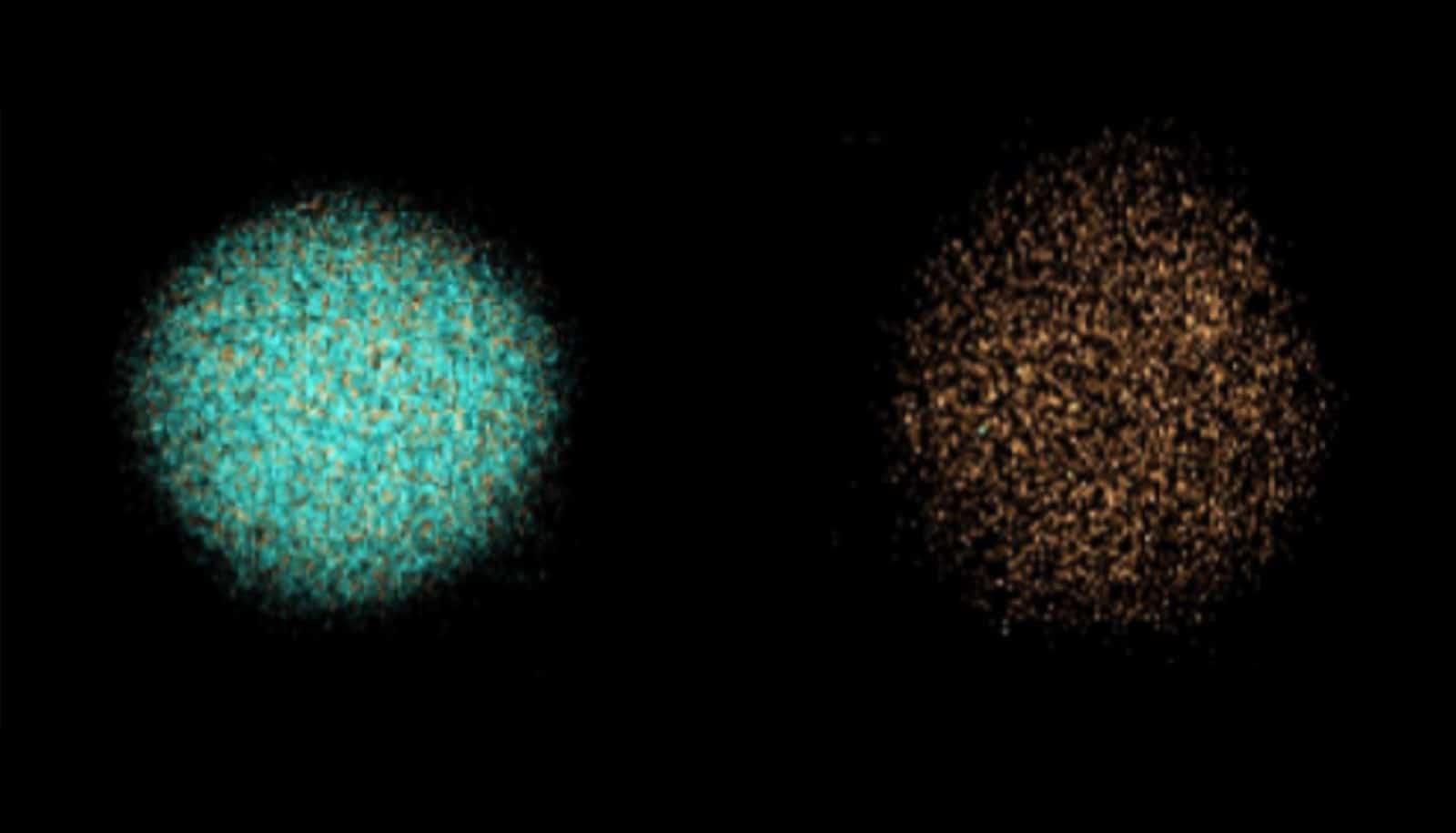

Initially, silver ions leach quickly from nanoparticles, which literally shrink as a result. As the process continues, the gold lattice in most instances releases all the silver over time, but about 25% of particles behave differently and silver leaching is incomplete.

Al-Zubeidi says what they observed suggests gold could be manipulated to stabilize the alloy nanoparticles.

“Usually silver leaching would last about two hours under our conditions,” he says. “Then in the second stage, the reaction no longer happens on the surface. Instead, as the gold lattice rearranges, the silver ions have to diffuse through this gold-rich lattice to reach the surface, where they can be oxidized. That slows the reaction rate a lot.

“At some point, the particles passivate and no more leaching can happen,” Al-Zubeidi says. “The particles become stable. So far, we’ve only looked at particles with a silver content of 80%-90%, and we found that a lot of the particles stop leaching silver when they reach a silver content of about 50%.

“That could be an interesting composition for applications like catalysis and electrocatalysis,” he says. “We’d like to find a sweet spot around 50%, where the particles are stable but still have a lot of their silver-like properties.”

Understanding such reactions could help researchers build a library of gold-silver catalysts and electrocatalysts for various applications.

“This effort will enable a new approach to generate nanostructured catalysts and new materials with unique electrochemical, optical and electronic properties,” says Robert Mantz, program manager for electrochemistry at the Army Research Office, an element of the US Army Combat Capabilities Command’s Army Research Laboratory. “The ability to tailor catalysts is important to achieve the goal of reducing soldier-borne weight associated with power storage and generation and enable novel material synthesis.”

Coauthors of the study are from Rice and Duisburg-Essen. The Army Research Office, a National Defense Science and Engineering Graduate Fellowship, the Robert A. Welch Foundation, the National Science Foundation, and the German Research Foundation supported the study.

Source: Rice University