Deep learning can speed up the analysis of gas chromatography data, researchers report.

Because this type of analysis is used in a variety of ways, the new method will have a major impact on quality, efficiency, and cost when examining various data—blood tests, oil pollution testing, the fermentation of cheese, and much more, researchers say.

Gas chromatography is a method of analysis that most people have experienced at one time or another without necessarily knowing it. For example, it can reveal food fraud or find out where a particular batch of cocaine was produced. It can also measure flavor and aroma in gastronomy and examine blood samples taken in the hospital.

“The new interpretive method of gas chromatographic analysis can make this type of analysis accessible to many more, which means that better and cheaper decisions can be made in a number of areas in society,” says Rasmus Bro, a professor in the food science department at the University of Copenhagen.

Faster fingerprints

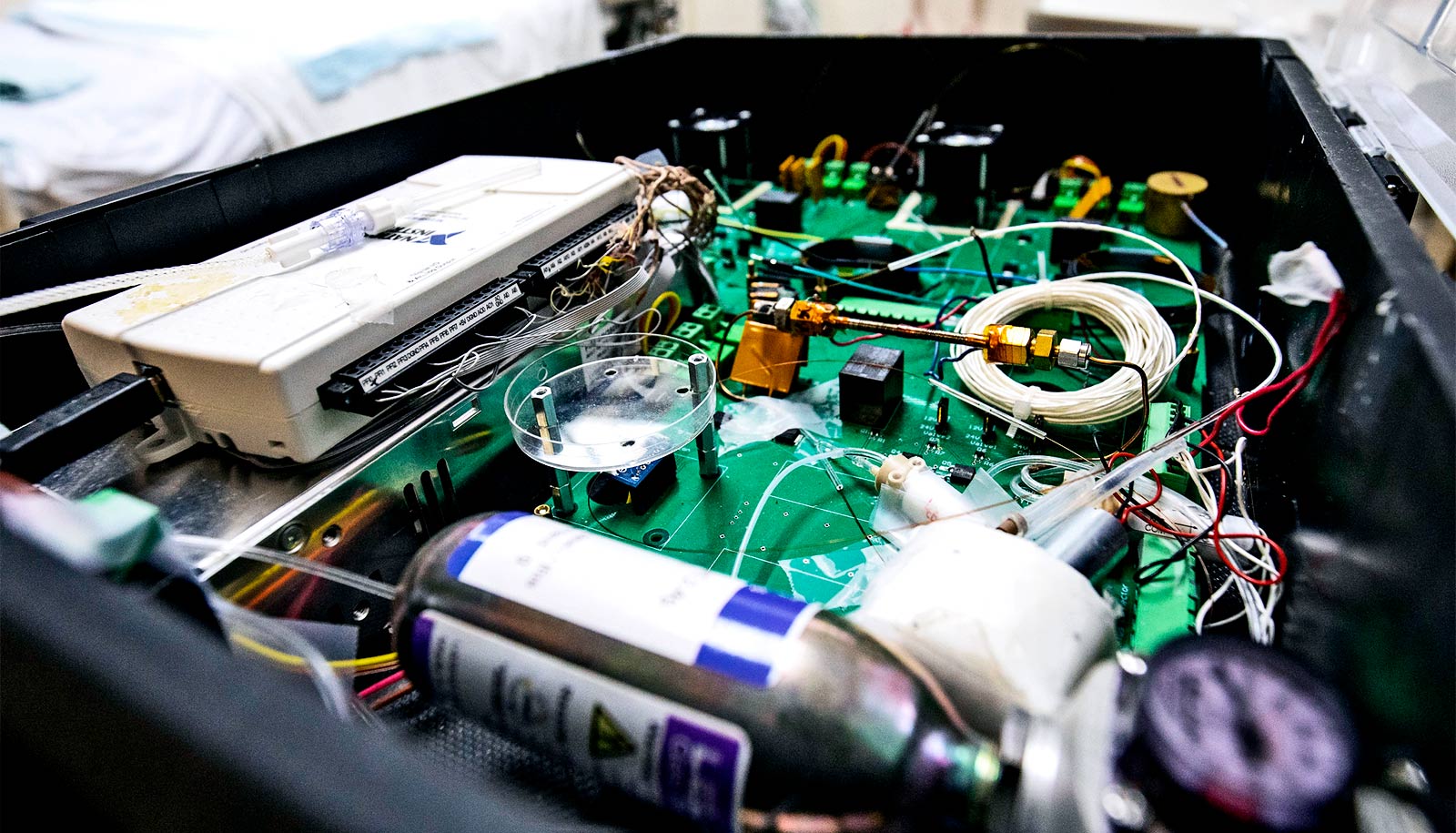

“Gas chromatography is one of the most widely used analytical methods and it provides a chemical profile that can reveal thousands of things. The analysis shows most of the chemical components in a sample of biological material in a particular pattern that can then be interpreted in terms of the specific things you want to examine. You could say that you take a chemical ‘fingerprint’ of the material,” says Bro.

Gas chromatography is generally important when talking about safety and improving the quality of global food production. Monitoring by means of measurements and artificial intelligence is one of the topics at a new major food conference, Food Day 2019, later this month.

Because it requires a highly specialized workforce, it is quite expensive to interpret the analyses.

“There is a great deal of manual work behind the interpretation of many gas chromatographic analyses and in some cases it takes several weeks to get the results from the measurements. With this research, we show that some of the most time consuming tasks can be done automatically by a computer,” says Anne Bech Risum, a PhD student.

The computer can make a number of decisions that usually require a chemist.

“The interpretation consumes a great deal of work because you work through the data bit by bit. A computer can do this much more efficiently and reproducibly,” explains Risum.

Gas chromatography for better food

The food industry widely employs gas chromatography using mass spectrometry. For example, all large companies that work with fermentation will use this method of analysis to measure how the microorganisms in a fermentation develop and affect the final product.

“If you, for example, produce a cheese, the taste and aroma develop differently depending on the microbiological culture you add and how you treat the cheese during production. Gas chromatography can be used to measure the chemical elements that together form the aroma profile of the cheese,” says Risum.

“So if you, for example, want a more fruity or nutty aroma, you could try to change the production and then measure whether you have formed more of the chemicals behind the desired flavor profile.”

The method of interpretation could also help give smaller food companies access to highly advanced analytical methods that can help companies with product optimization, quality assurance, and raw material identification.

Funding for the research came from FOSS and Arla.

Source: University of Copenhagen