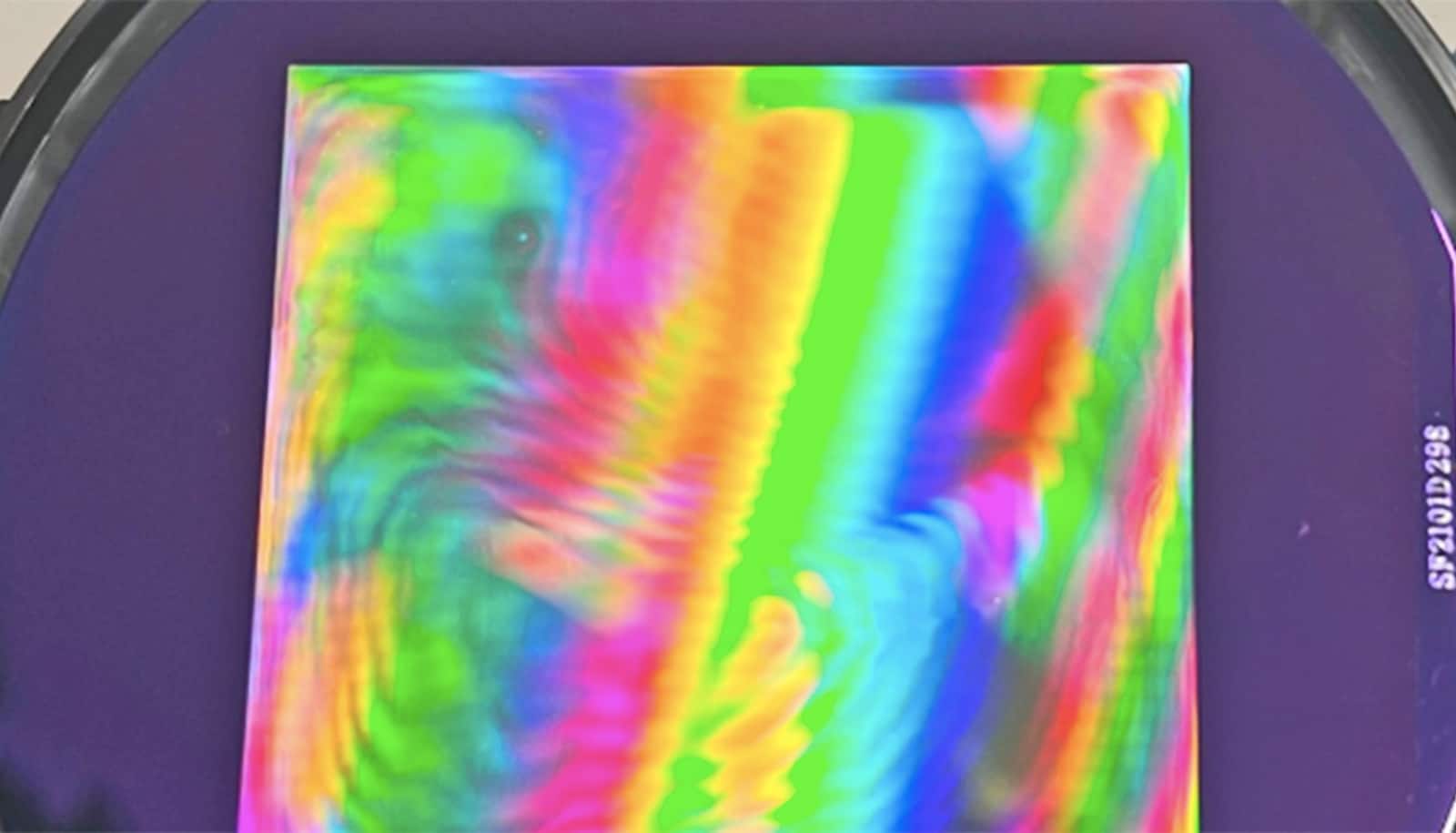

A fast, cheap, and eco-friendly method converts cotton-based fabric waste, like unwanted clothing, into aerogels.

The ultra-light and highly compressible aerogels could be useful for a range of things, including control of rapid bleeding and heat insulation.

Aerogels are among the lightest materials in the world and are highly porous with strong absorption capacity and low thermal conductivity. These unique properties make aerogels highly suitable for applications in areas including oil-spill cleaning, personal care products such as diapers, and heat and sound insulation.

Since aerogels’ creation in the 1930s, high production costs have kept industries from widely adopting them.

Led by associate professor Hai Minh Duong and professor Nhan Phan-Thien from the department of mechanical engineering at the NUS Faculty of Engineering, the research team discovered that the novel cotton aerogels can be easily compressed, and they can also very quickly recover up to 97 percent of their original size when placed in water.

“This new eco-friendly cotton aerogel is a major improvement from the aerogel that our team had previously developed using paper waste. It is highly compressible, hence storage and transportation costs could be greatly reduced,” says Duong.

“Furthermore, these cotton aerogels can be fabricated within eight hours—this is nine times faster than our earlier invention and about 20 times faster than current commercial fabrication processes. They are also stronger, making them more suitable for mass production.

“While we have demonstrated novel application of the cotton aerogels for effective hemorrhage control and heat insulation, we will continue to explore new functions for this advanced material.”

Control bleeding fast

Hemorrhage, or the excessive and rapid loss of blood, resulting from gunshot or other deeply penetrating wounds, can often be life threatening. Hemorrhage control devices exert internal pressure to stop bleeding and promote blood clotting.

Existing hemorrhage control devices comprise a syringe filled with small capsules of cellulose-based sponge coated with chitosan, a natural agent derived from the shells of shrimp and other crustaceans that promotes blood clotting. The syringe goes into the wound to release the capsule, which expands and applies pressure on the wound to stop the blood flow. However, the expansion and absorption rates of cellulose-based sponges are still relatively slow.

To address these limitations, the researchers developed highly compressible hybrid cotton aerogel pellets that are more effective than cellulose-based sponges for treatment of deep hemorrhagic wounds. These pellets—comprising an optimal mix of cotton and cellulose aerogels coated with chitosan—are simple and cost-effective to produce, and are easy to integrate into a clinical syringe for hemorrhage control. The cotton aerogel pellets are also biocompatible.

This gold aerogel is almost as light as air

“Each cotton aerogel pellet can expand to 16 times its size in 4.5 seconds—larger and more than three times faster than existing cellulose-based sponges—while retaining their structural integrity. The unique morphology of the cotton aerogels allows for a larger absorption capacity, while the compressible nature enables the material to expand faster to exert pressure on the wound,” adds Duong.

The findings appear in Colloids and Surfaces A.

Canteen jackets

Soldiers regularly embark on vigorous physical activities in hot and humid conditions. The military canteen is an essential item in a soldier’s survival kit, carrying fluid for rehydration and mitigation of heat injuries. A military canteen can typically hold one liter of water and maintain its cool temperature for about 30 minutes in a tropical climate.

The NUS research team, in collaboration with DSO National Laboratories, developed a lightweight thermal jacket to maintain the temperature of ice at 0.1 to 1.0 degree Celsius for more than four hours. The thermal jacket, which weighs about 200 grams, consists of a cotton aerogel layer embedded within commonly used fabrics to provide heat insulation.

Souped-up cotton gives clothing new powers

The cotton aerogel-insulated military canteen offers better heat insulation performance compared to commercial insulated water bottles such as FLOE bottles, and is highly comparable to that of vacuum flasks. However, FLOE bottles and vacuum flasks are much heavier and more costly.

“The heat insulation property of the novel cotton aerogels can be applied to various consumer products, such as cooler bags, to keep food items fresh. We also foresee tremendous potential for other high value applications, such as pipeline insulation and transportation of liquefied natural gas which needs to be stored at a low temperature,” says Nhan.

The NUS team has filed a patent for the novel cotton aerogels and is exploring opportunities to work with companies to commercialize the technology.

Source: National University of Singapore