A new coating prevents fogging on transparent surfaces, researchers report.

Going into a warm humid environment from the cold can cause eyeglasses or camera lenses to fog up, but the new coating uses sunlight to clear things up.

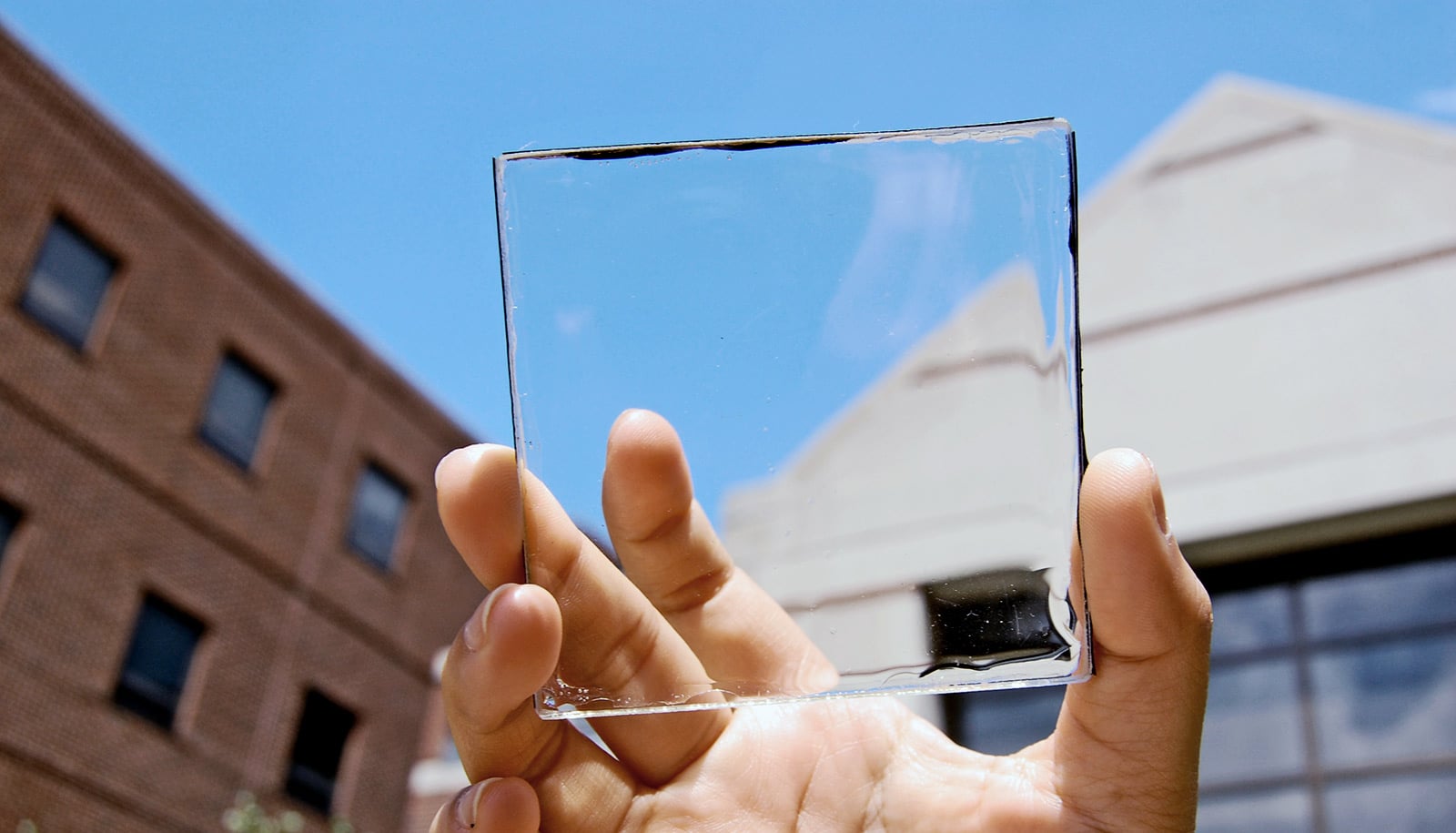

Since the only energy source required is the sun, the coating works especially well for wearable items such as glasses and goggles. Researchers made the transparent durable coating, which is just a few nanometers thick, of gold nanoparticles embedded in non-conductive titanium oxide.

“Our coating absorbs the infrared component of sunlight along with a small part of the visible sunlight and converts the light into heat,” says lead author Christopher Walker, a doctoral student working with Dimos Poulikakos, a professor at ETH Zurich. The process heats the surface up about 3 to 4 degrees Celsius—the difference in temperature that prevents fogging.

Heat also solves the problem of fogging on car windows. Warm air from the in-vehicle heating system heats the front windshield, while the rear window uses a grid of electrical heating elements. Unlike these methods, the researchers’ new coating works passively.

“Normally, it’s dark surfaces that absorb light and convert it into heat,” says Efstratios Mitridis, another doctoral student in Poulikakos’s group. “But we’ve created a transparent surface that has the same effect.”

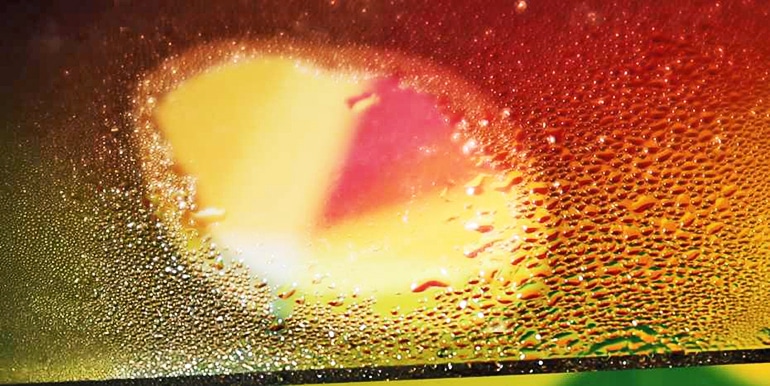

Condensation occurs on a surface whenever there is a sudden drop in temperature or increase in humidity, forming tiny droplets of water that disperse incident light in different directions in much the same way as atmospheric fog.

As an alternative to using heat to prevent fogging, hydrophilic agents can coat susceptible surfaces. Because they attract water, these agents ensure that the condensation forms an even thin film of liquid over the surface rather than separate droplets. Anti-fog sprays for glasses usually work on this principle.

Now, tests have shown that when exposed to sunlight, fogged surfaces coated with gold nanoparticles and titanium oxide clear four times faster than surfaces treated with a normal anti-fog agent.

“Spray treatments often lose their effect after a while because the anti-fog film dries up or becomes unevenly distributed,” Walker says. “A durable coating like ours lasts much longer than a spray treatment, which you have to apply virtually on a daily basis.”

The scientists say they plan to bring the new method to market, in collaboration with an industry partner.

“We’re looking to refine our already robust coating to ensure it lasts for years, and we want to take the technology from lab scale to industry scale,” Walker says.

Source: ETH Zurich