Researchers have discovered a new type of cellulose in bacteria that has properties that could make it an improvement over traditional cellulose for fuels and other materials, or for better understanding and treating bacterial infections.

Produced by plants, algae, and some bacteria, cellulose is an abundant molecule involved in the production of hundreds of products, from paper to fabrics to renewable building materials. It’s also one starting material for producing ethanol, a common fuel additive and renewable fuel source.

The researchers describe this modified cellulose, called pEtN, and its possible applications in the journal Science.

“Cellulose is one of the most well studied polymers in nature,” says Lynette Cegelski, an assistant professor of chemistry and senior author on the paper. That fact made it all the more surprising when the scientists found the new cellulose, and from one of the best studied bacteria—E. coli.

All the benefits, fewer drawbacks

Cegelski’s work was originally motivated by her fascination with microbes and the matrix of slime-like materials that surrounds them and protects their communities. That matrix performs many functions for the bacterial community, like sharing nutrients and protecting the community from antibiotics and the host immune system.

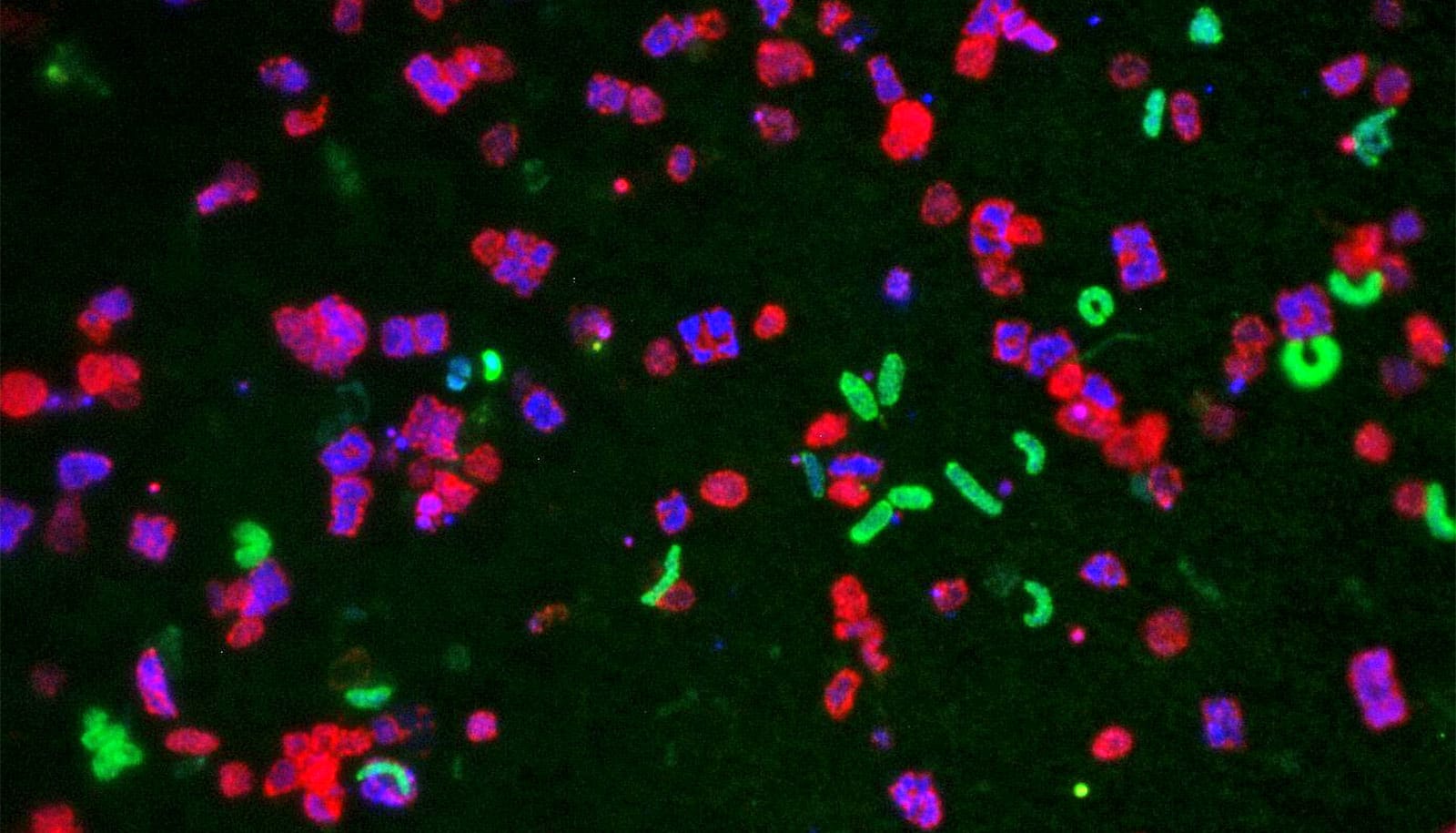

It was within that extracellular latticework that the team originally noticed a modified form of cellulose. It had been missed by decades of previous research because traditional lab techniques involve harsh chemicals that stripped the modification.

In their current work, Cegelski and graduate student Wiriya Thongsomboon set out to better understand the novel cellulose. In the process, they discovered that this new form had properties that they think could make it an improvement over other sources of cellulose—like switchgrass, miscanthus, or poplar—for producing ethanol for fuels.

It turns out that the modified cellulose doesn’t form crystals and is relatively soluble in water, which the researchers think could make it easier and significantly less expensive to convert into glucose—the starting material for producing ethanol.

Currently, ethanol can be made cheaply from the sugary kernals of corn, but corn can only grow in limited areas, and ethanol production competes with corn as a food source.

Young poplars could be next biofuel source

Ethanol produced from cellulose is preferable because it makes use of the entire plant rather than just the kernals, doesn’t compete with a food source, and could be grown in many areas. But traditional sources of cellulose are expensive to convert into glucose.

If further research supports the researchers’ initial findings, this new source could have all the environmental benefits of traditional cellulose, but at a lower cost.

‘The sky is the limit’

The group also believes their finding could have medical applications. The modified cellulose nurtures and surrounds bacterial colonies making up some infections. Cegelski and her collaborators are now testing in mice whether inhibiting its production could help treat those infections.

In addition, they are exploring the mechanical properties of pEtN compared to other forms of cellulose.

“The sky is the limit with possible applications of this new material,” Cegelski says. “Biomedical applications, materials applications, basic chemical uses. Maybe even the next carbon fiber precursor.”

For better biofuel, ‘sew’ best bits of bacteria together

In their research, Cegelski and her team explored not only the structure of the new cellulose but also the genes and molecules involved in making it. In the process, they discovered the enzymes that modify the cellulose after it is produced.

Cegelski is now trying to find plant biologists to help introduce genes for making the modified cellulose from bacteria into plants. Plants make more cellulose and are easier to grow on a large scale to produce the volume needed for most applications. They are also exploring additional types of modifications and ways of creating novel forms of cellulose.

Additional researchers from Stanford and from Humboldt University of Berlin contributed to the work. Funding for the research came from Stanford’s Precourt Institute for Energy.

Source: Stanford University