A new mouthguard device may soon give people with limited hand function a way to easily control devices such as computers, smartphones, and wheelchairs.

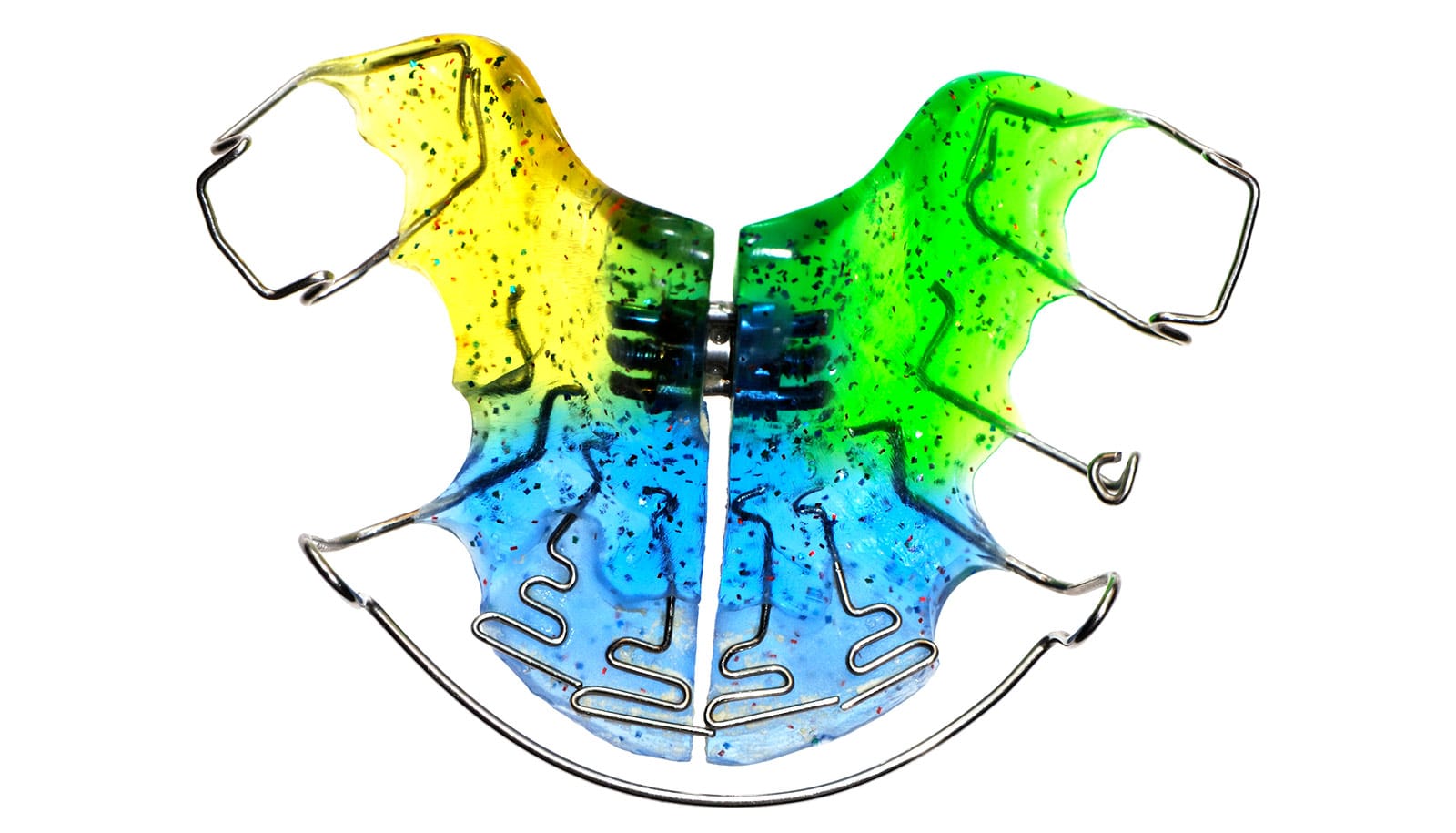

The mouthguard, a first-of-its-kind bite-controlled optoelectronic system, translates complex bite patterns accurately and quickly into instructions to control these kinds of electronic gadgets.

Various assistive technologies such as voice recognition, eye tracking, and brain-computer interfaces have been developed in recent years to help people—especially those with limited dexterity or neurological disorders—control electronic devices. However, these technologies have limitations associated with environmental interference, control accuracy, cost, and maintenance.

To offer an alternative to existing assistive technologies, Liu Xiaogang, a professor in the chemistry department at the National University of Singapore Faculty of Science, and his team successfully designed and demonstrated the smart mouthguard, which contains integrated pressure sensors to detect occlusal patterns. These patterns are translated into data inputs with 98% accuracy, and can be used to control computers, smartphones, and wheelchairs.

Besides supporting human-computer interaction, the mouthguard can also be used for medical assistance, health care devices such as smart electronic skin and dental diagnosis.

Less invasive

Assistive technologies help to promote independence and autonomy for people with disability. Unfortunately, such technologies also have significant drawbacks.

For example, voice recognition requires a large operating memory and needs to operate in a low-noise environment, while eye tracking requires a camera to be mounted in front of the user and is prone to fatigue. Although brain-computer interfaces have improved considerably in recent years, this technology is invasive and requires cumbersome wired instruments.

Bite force, often used as a parameter to assess masticatory (chewing) function, is a promising area that is not well understood or capitalized. As dental occlusion provides high-precision control and requires minimal skill, Liu and his team came up with a new concept for assistive technology by utilizing unique patterns of occlusal contacts.

Bite-based assistive tech

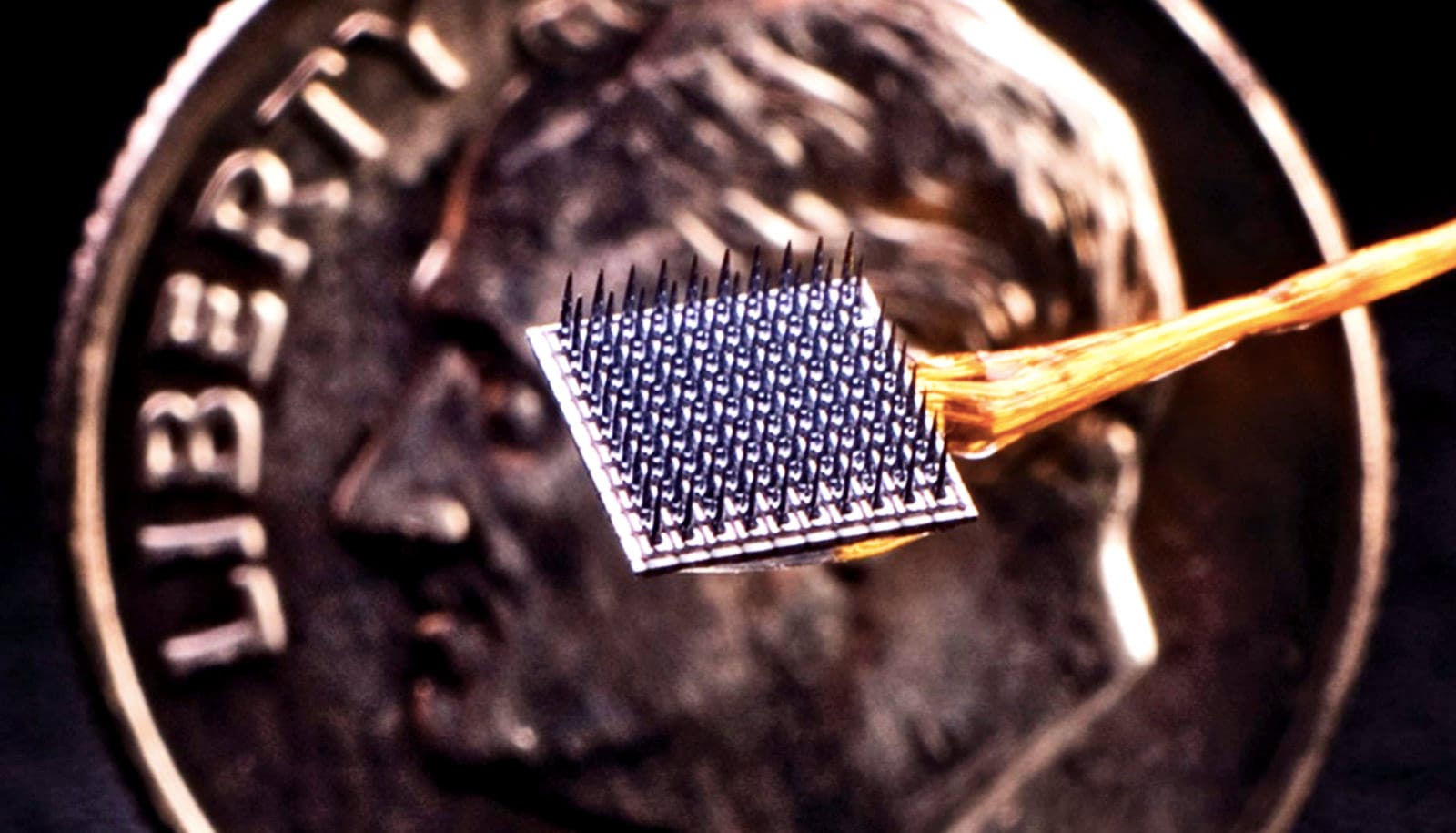

The research team first designed a sensor comprising a series of contact pads containing different colored phosphors—substances that emit light in response to pressure. The array of contact pads is placed within a flexible mouthguard.

Biting causes the contact pads to mechanically deform and emit light in different colors and intensities, which can be measured and processed using machine learning algorithms. The data collected is then used for high-accuracy remote control and operation of various electronic devices.

Weighing about 7 grams, the mouthguard requires less training experience when compared to existing assistive technologies.

“Our bite-controlled optoelectronic system is capable of translating complex bite patterns into data inputs with 98% accuracy. We have also demonstrated that our novel sensors can distinguish mechanical deformations, including strain, compression, and bending, making them applicable to multifunctional mechanical sensing applications, such as miniaturized force sensing, flexible electronics, artificial skin, and dental diagnosis,” Liu says.

Each smart mouthguard currently costs S$100 (about $70 US) to produce in the lab, and the team expects the cost to be reduced substantially in mass production. Although the current prototype is designed for well-aligned teeth, a mouthguard with an irregular arrangement of phosphor-infused pads could be developed for users with different tooth patterns or for individuals who wear dentures.

The study appears in the journal Nature Electronics.

The research team has filed a patent for this innovative technology, and are exploring opportunities to validate their device in a clinical setting, such as care centers or nursing homes. Concurrently, the researchers are also looking at ways to enhance their technology, such as faster data processing and training.

Source: NUS