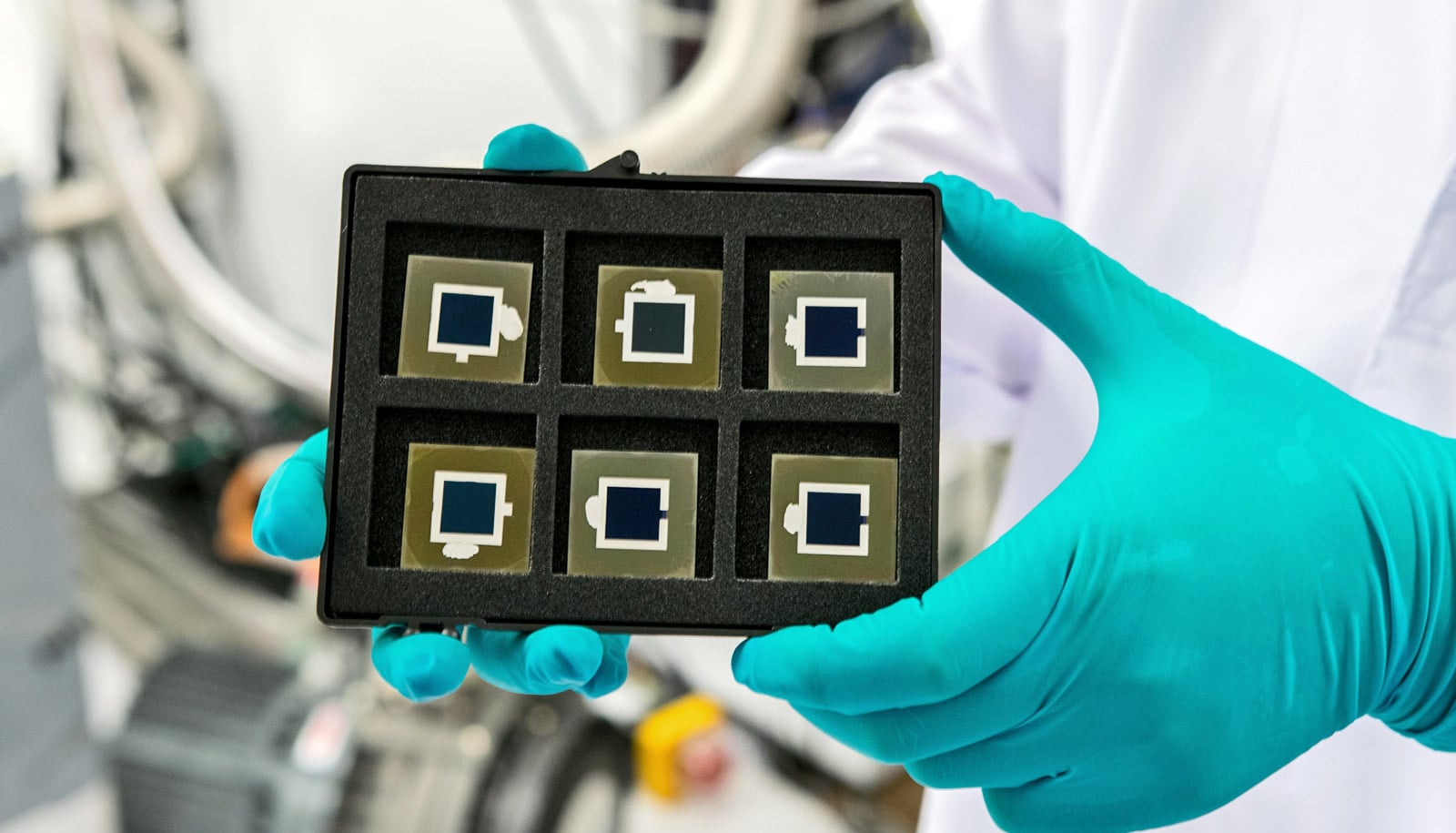

Researchers have developed a method to make high-quality perovskite films at room temperature.

Finding reliable, eco-friendly power sources is crucial as our world grapples with increasing energy needs and the urgent call to combat climate change. Solar energy offers one solution, with scientists devising ever more efficient materials for capturing sunlight.

Perovskite solar cells have emerged as a promising alternative to conventional, silicon solar cells, boasting a number of advantages. But processing the material has been a complicated affair.

The new innovation not only simplified the production process but also increased the material’s efficiency from under 20% to 24.4%.

The details appear in the journal Joule.

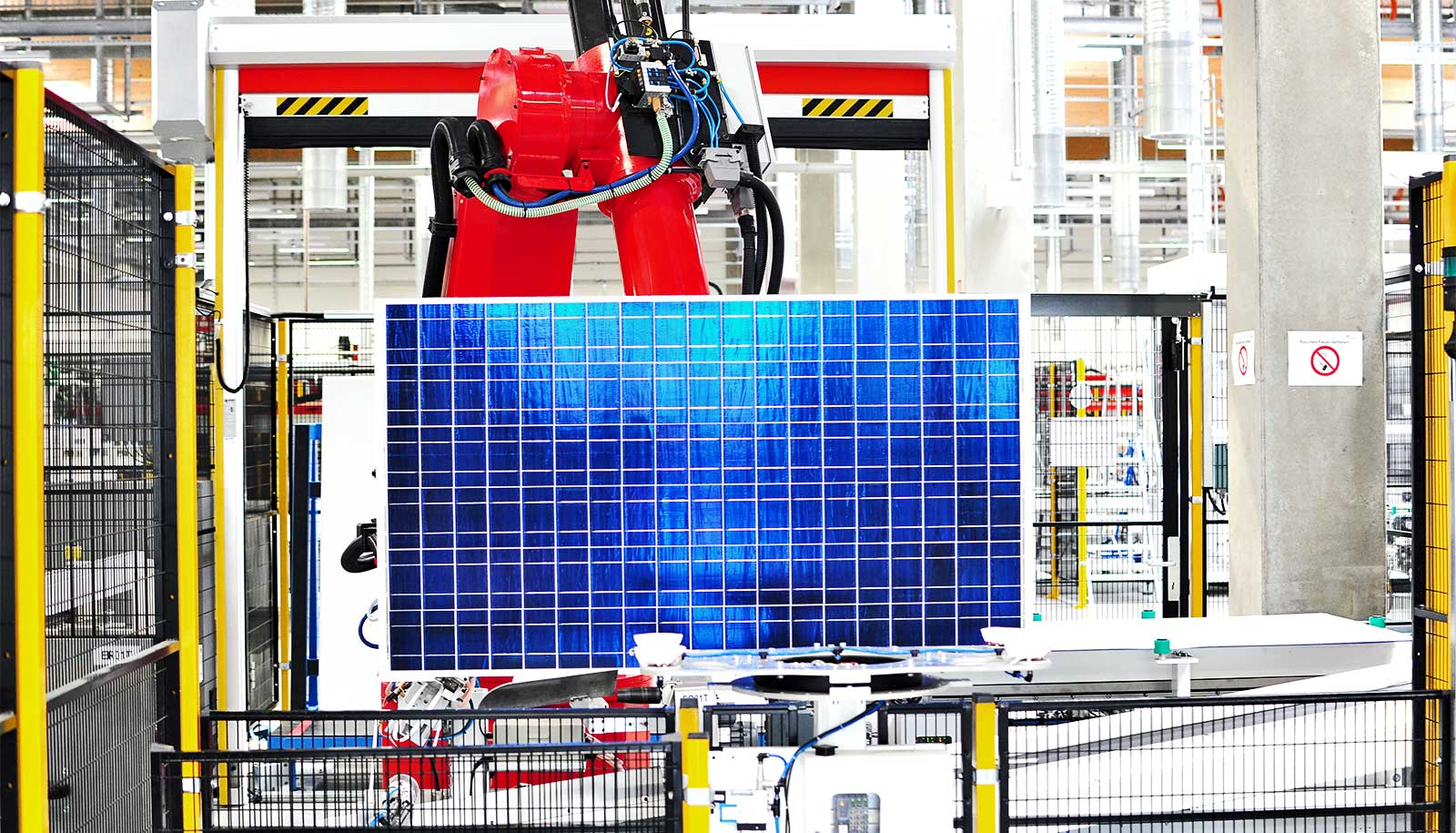

Perovskite is a class of materials characterized by its specific crystal structure, exemplified by the mineral of the same name. Solar cells made from this material boast many advantages compared to silicon-based solar cells. They’re lightweight, flexible, and can be applied as a spray or printed like ink. Perovskite solar cell production also has the potential for a smaller carbon footprint than silicon photovoltaics, which require high temperatures and a cleanroom environment.

That said, producing these cells involves high-temperature annealing and tricky post-treatment steps, significantly slowing fabrication and making it hard to incorporate them into everyday items. These factors impede perovskite’s adoption in large-scale manufacturing and make them less environmentally friendly.

By fine tuning the material’s chemical composition, the authors developed a perovskite ink that created high-quality films much more effectively.

“Our method follows the same procedures as the conventional one, except for omitting the two most time-consuming steps: thermal annealing and post-treatment,” says co-lead author Ahra Yi, a postdoctoral researcher at UC Santa Barbara. The simpler fabrication technique also meshes better with standard manufacturing processes and reduces the overall energy use, which lowers its carbon dioxide emissions.

What’s more, the new material outperformed cells made using the high-temperature process.

“Our optimized perovskite solar cell achieved a remarkable efficiency of 24.4%,” says co-lead author and doctoral student Sangmin Chae, “surpassing previous limits, which were below 20% for room-temperature processed devices.”

The new procedure is also extremely gentle. To demonstrate this, the team prepared a perovskite layer on fresh leaves, a feat that was impossible with the previous, high-temperature process.

“We thought this choice would be both eye-catching and symbolic, since solar cells mimic the photosynthetic process in leaves,” says Yi.

This versatility opens up a wide range of possible applications. It’s well suited for flexible indoor and outdoor energy generation.

“With our approach, we can now contemplate the development of high-efficiency solar cells with free-form designs capable of powering the ever-increasing array of wearable electronics, sensors, displays, security cameras, Internet of Things (IoT) devices, et cetera,” says senior author Thuc-Quyen Nguyen, and professor and director of the UCSB Center for Polymers & Organic Solids.

Source: UC Santa Barbara