A new type of cooling cube could revolutionize how food is kept cold and shipped fresh without relying on ice or traditional cooling packs.

The plastic-free, “jelly ice cubes” don’t melt, are compostable and anti-microbial, and prevent cross-contamination.

“When ice melts, it’s not reusable,” says Gang Sun, a professor in the biological and agricultural engineering department at the University of California, Davis. “We thought we could make a so-called solid ice to serve as a cooling medium and be reusable.”

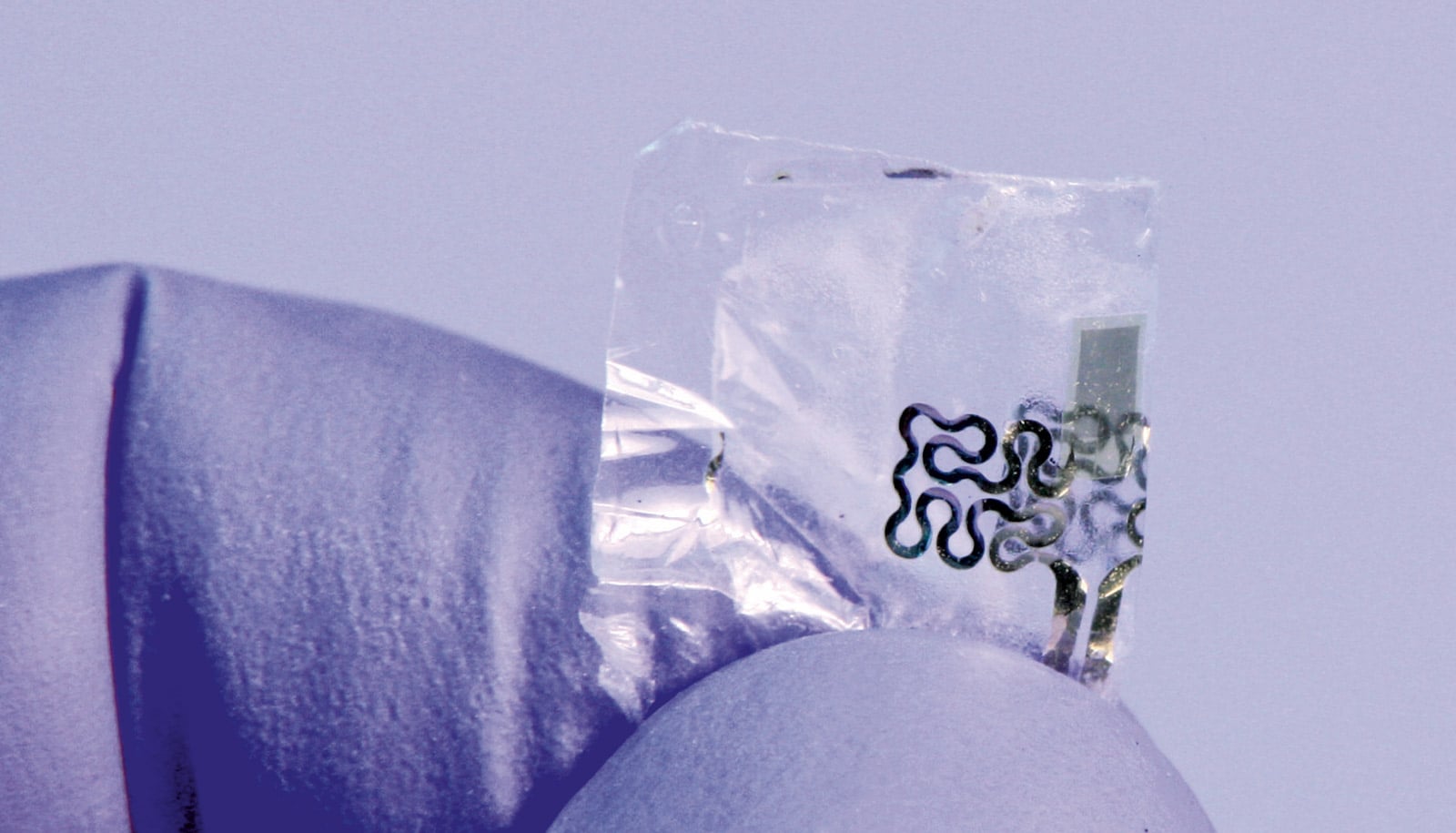

The cooling cubes contain more than 90% water and other components to retain and stabilize the structure. They are soft to the touch like a gelatin dessert and change color depending on temperature.

The reusable cubes can be designed or cut to any shape and size needed, says Jiahan Zou, a PhD graduate student who has been working on the project the past two years.

“You can use it for 13 hours for cooling, collect it, rinse it with water, and put it in the freezer to freeze again for the next use,” Sun adds.

The researchers hope to eventually use recycled agriculture waste or byproduct as the coolant material.

“We want to make sure this is sustainable,” says Luxin Wang, an associate professor in the food science and technology department.

The researchers began working on the coolant cubes after Wang saw the amount of ice used at fish-processing plants and the cross-contamination that meltwater could spread among products or down the drain. “The amount of ice used by these fish-processing sites is massive,” Wang says. “We need to control the pathogens,” he says.

Sun also lamented mold found in the plastic ice packs used with school lunches for kids and frequently found in shipping packages.

Early tests have shown the cubes can withstand up to 22 pounds without losing form. They can be reused a dozen times—just a quick wash with water or diluted bleach—and then disposed of in the trash or with yard waste.

The jelly ice cubes offer an alternative to traditional ice and could potentially reduce water consumption and environmental impact. They also offer stable temperatures to reduce food spoilage and could be ideal for meal prep companies, shipping businesses, and food producers who need to keep items cold.

The application could potentially control microbial contaminations to reduce water consumption in the food supply chain and food waste.

The research appears in the journal Sustainable Chemistry & Engineering.

Researchers filed a patent for the design and concept in July. The USDA National Institute of Food and Agriculture funded the work.

Source: UC Davis