New research could lead to injectable gels that release medicines over time.

Injecting patients with a gel that would dissolve over several months could replace the need to administer daily or weekly shots. But to make this possible, researchers first had to create a Jello-like substance that could defy one of the fundamental laws of nature.

Gels are formed when polymers mixed into fluids create gooey substances useful for everything from holding hair in place to enabling contact lenses to float over the eye.

“We can make gels with the right slow-release properties at room temperature but once we injected them, body heat would rapidly dissolve them and release the medicines too quickly,” says Eric Appel, assistant professor of materials science and engineering at Stanford University.

Medicinal Jello

In a paper published in Nature Communications, Appel and colleagues detail their successful first step toward making temperature-resistant, injectable gels with a concoction designed to cleverly bend the laws of thermodynamics.

Appel describes the science behind this rule-breaking with an analogy to making Jello: the solid ingredients are poured into water, then heated and stirred to mix well. As the mixture cools, the Jello solidifies as the molecules bond together. But if the Jello is reheated, the solid reliquefies.

The Jello example illustrates the interplay between two thermodynamic concepts—enthalpy, which measures the energy added to or subtracted from a material, and entropy, which describes how energy changes make a material more or less orderly at the molecular level.

Appel and his team had to make a medicinal Jello that didn’t melt, thus losing its time-release properties, when the body heated the cool solid.

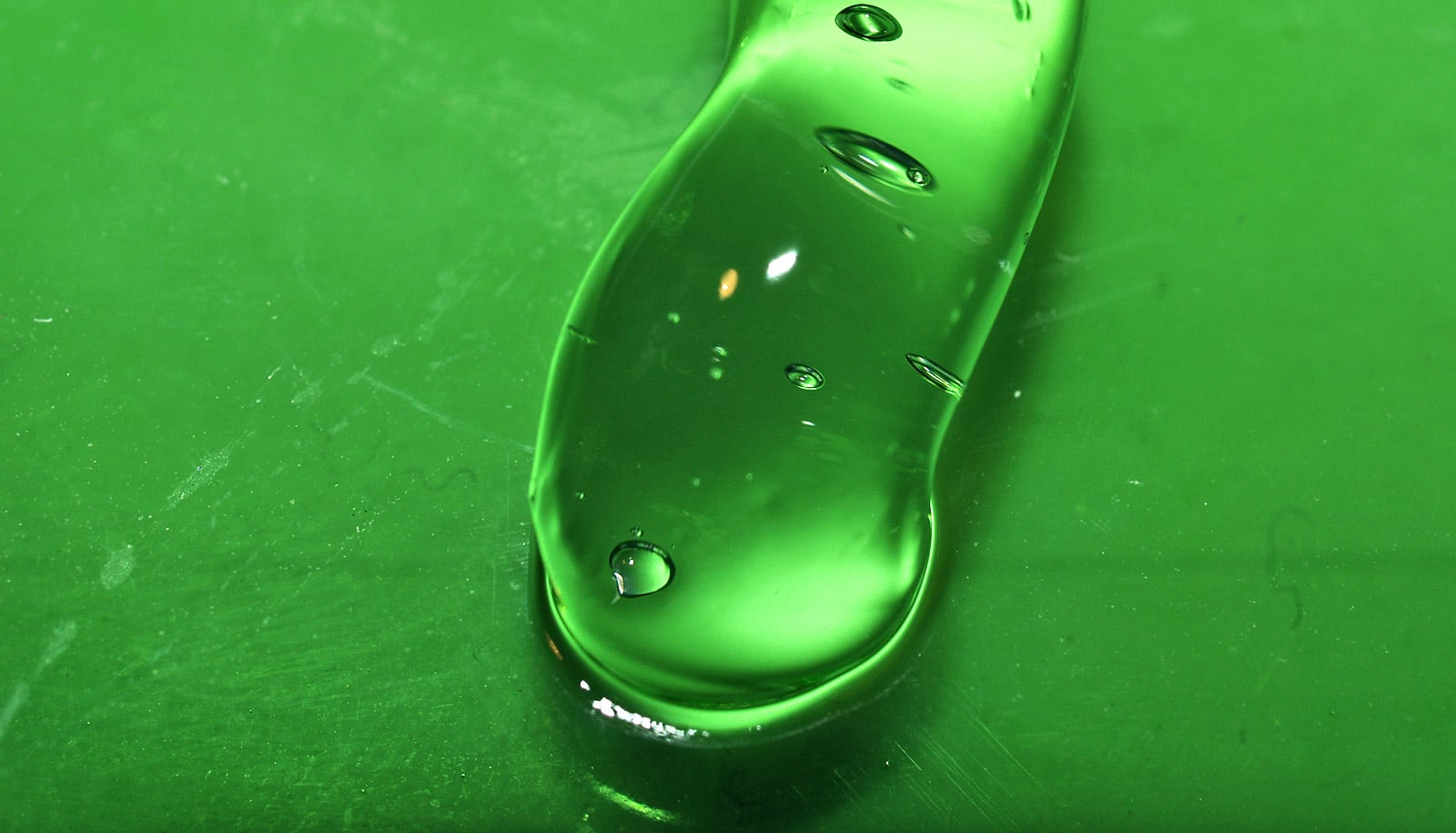

To accomplish this the team created a gel made of two solid ingredients—polymers and nanoparticles. The polymers were long, spaghetti-like strands that have a natural propensity to get entangled, and the nanoparticles, only 1/1000th the width of a human hair, encouraged that tendency.

The researchers began by separately dissolving the polymers and particles in water and then stirring them together. As the commingling ingredients began to bond, the polymers wrapped tightly around the particles.

“We call this our molecular Velcro,” says first author Anthony Yu, who did the work as a Stanford graduate student and is now a postdoctoral scholar at Massachusetts Institute of Technology.

The powerful affinity between the polymers and particles squeezed out the water molecules that had been caught between them, and as more polymers and particles congealed, the mixture began to gel at room temperature.

Making gels biocompatible

Crucially, this gelling process was achieved without adding or subtracting energy. When the researchers exposed this gel to the body’s temperature (37.5 C or 99.5 F) it didn’t liquefy like ordinary gels because the molecular Velcro effect enabled entropy and enthalpy—orderliness and temperature change, respectively—to remain roughly in balance in accord with thermodynamics.

It will take more work to make injectable, time-release gels safe for human use, Appel says. While the polymers in these experiments were biocompatible, the particles were derived from polystyrene, which is commonly used to make disposable cutlery. His lab is already trying to make these thermodynamically-neutral gels with fully biocompatible components.

If they are successful, a time-release gel could prove valuable for providing anti-malarial or anti-HIV treatments in under-resourced areas where it’s difficult to administer the short-acting remedies currently available.

“We are trying to make a gel that you could inject with a pin, and then you’d have a little blob that would dissolve away very slowly for three to six months to provide continuous therapy,” Appel says. “This would be a game-changer for fighting critical diseases around the world.”

Source: Stanford University