Researchers have created a novel film that is very effective in evaporating sweat from our skin to keep us cool and comfortable when we exercise.

The moisture from sweat can also power wearable electronic devices such as watches, fitness trackers, and more, the researchers report.

“Sweat is mostly composed of water. When water is evaporated from the skin surface, it lowers the skin temperature and we feel cooler,” says Tan Swee Ching, assistant professor from NUS Materials Science and Engineering and research team leader.

“In our new invention, we created a novel film that is extremely effective in evaporating sweat from our skin and then absorbing the moisture from sweat. We also take this one step further—by converting the moisture from sweat into energy that could be used to power small wearable devices.”

The main components of the thin film are two hygroscopic chemicals—cobalt chloride and ethanolamine. Besides being extremely moisture-absorbent, the film can rapidly release water when exposed to sunlight, and it can be “regenerated” and reused more than 100 times.

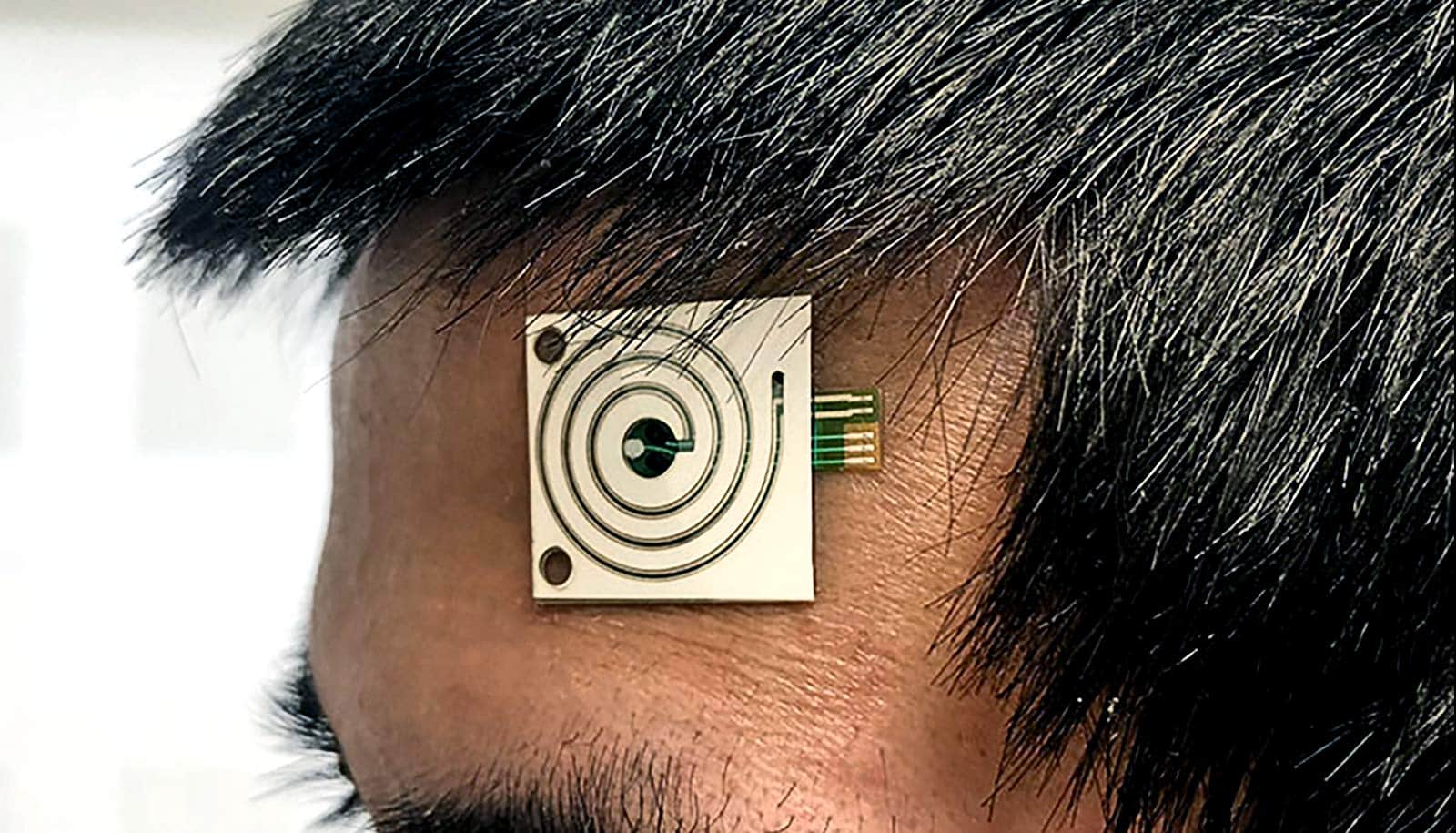

To make full use of the absorbed sweat, the team also designed a wearable energy harvesting device comprising eight electrochemical cells (ECs), using the film as the electrolyte. Each EC can generate about 0.57 volts of electricity upon absorbing moisture.

The overall energy the device harvests is sufficient to power a light-emitting diode. This proof-of-concept demonstration illustrates the potential of battery-less wearables powered using human sweat.

Conventional hygroscopic materials such as zeolites and silica gels have low water uptake and bulk solid structures, making them unsuitable for absorbing moisture from sweat evaporation. In comparison, the new moisture-absorbing film takes in 15 times more moisture and does this six times faster than conventional materials.

In addition, the film changes color upon absorbing moisture, from blue to purple, and finally pink, which can indicate the degree of moisture absorption.

The team packaged the film into breathable and waterproof polytetrafluoroethylene (PTFE) membranes, which are flexible and commonly used in clothing, and successfully demonstrated the application of the moisture-absorption film for underarm pads, shoe linings, and shoe insoles.

“Underarm sweating is embarrassing and frustrating, and this condition contributes to the growth of bacteria and leads to unpleasant body odor,” Tan says. “Accumulation of perspiration in the shoes could give rise to health problems such as blisters, calluses, and fungal infections.

“Using the underarm pad, shoe lining, and shoe insole embedded with the moisture-absorbing film, the moisture from sweat evaporation is rapidly taken in, preventing an accumulation of sweat and provides a dry and cool microclimate for personal comfort.”

“The prototype for the shoe insole was created using 3D printing. The material used is a mixture of soft polymer and hard polymer, thus providing sufficient support and shock absorption,” says team co-leader Ding Jun, a professor also from the NUS Materials Science and Engineering.

The team now hopes to work with companies to incorporate the novel moisture-absorption film into consumer products.

The study appears in Nano Energy.

Source: National University of Singapore