Fluorine, a relatively abundant and light element, may serve as an alternative to lithium in rechargeable batteries, a new study shows.

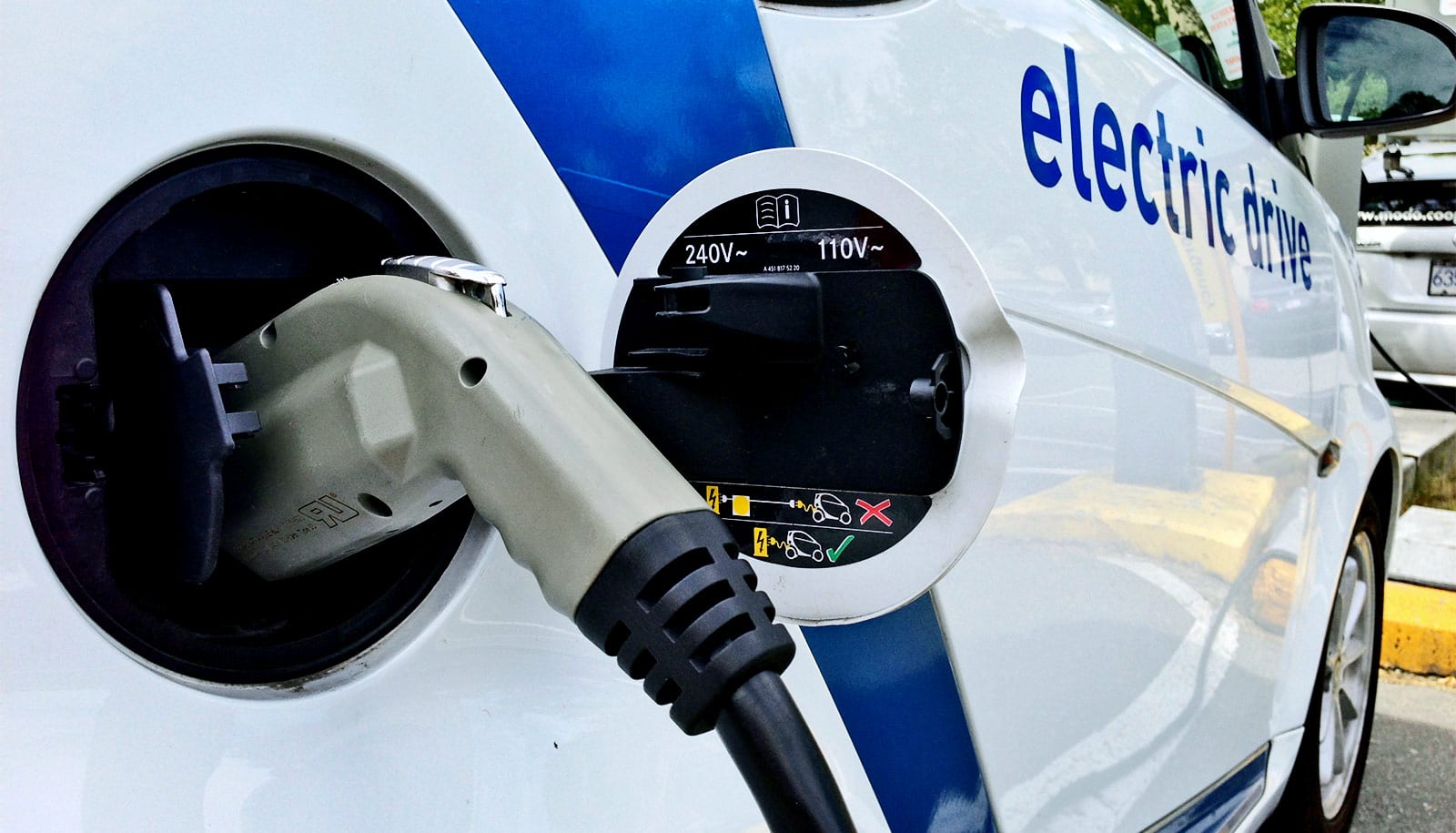

With increased use of rechargeable batteries to power modern technology, particularly electric vehicles, researchers have been looking for alternative materials for lithium-ion in rechargeable batteries. Modern batteries use lithium and cobalt, but these have a very limited supply.

Interestingly, the fluoride ion is the mirror opposite of the lithium ion, having the strongest attraction for electrons, which allows it to easily carry out electrochemical reactions.

Researchers in Japan are also testing fluoride-ion batteries as possible replacements for lithium-ion batteries in vehicles. They say these batteries could allow electric vehicles to run 1,000 kilometers (621 miles) on a single charge. However, current fluoride-ion batteries have poor cyclability, which means they tend to degrade rapidly with charge-discharge cycles.

In their new work, the researchers adopted a different approach to fluoride-ion battery design, identifying two materials that easily gain or lose fluoride ions while undergoing small structural changes to enable good cyclability.

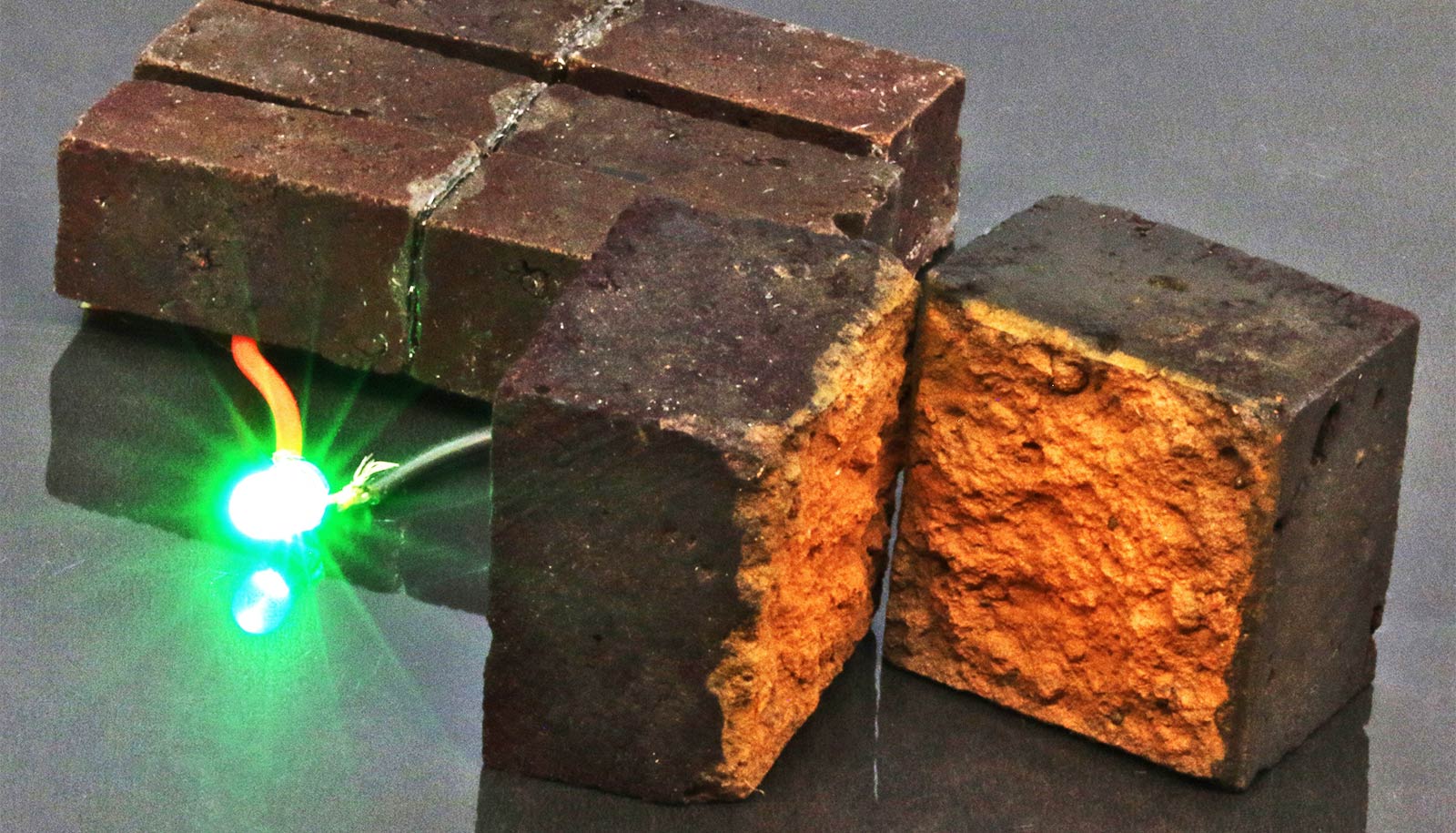

The new battery materials are both layered electrides, says Rohan Mishra, assistant professor of mechanical engineering and materials science at Washington University in St. Louis.

Electrides are a relatively new class of materials that researchers have known about in principle for about 50 years, but it wasn’t until the past 10 to 15 years that their properties were better understood, Mishra says.

While these materials conduct electrons like ordinary metals, unlike the “sea of electrons” in metals where the electrons are delocalized throughout the crystal, in electrides, the electrons reside at specific interstitial sites within the crystal structure, similar to an ion.

“We predict that these interstitial electrons can be easily replaced with fluoride ions without significant deformations to the crystal structure, thus enabling cyclability,” Mishra says. “The fluoride ions can also move or diffuse fairly easily due to the relatively open structure of the layered electrides.”

Steven Hartman, an alumnus of the Institute of Materials Science & Engineering who earned a doctorate in Mishra’s lab prior to accepting a postdoctoral fellowship at Los Alamos National Laboratory, used quantum-mechanical calculations to test dozens of potential battery candidates.

The computerized tests introduced fluoride into the interstitial spaces of the layered electrides dicalcium nitride and yttrium hypocarbide. Energy storage capabilities were close to the performance of lithium-ion batteries. In the case of dicalcium nitride, it is made up of relatively abundant elements and can help to overcome the supply shortage of elements currently used in lithium-ion batteries.

Hartman contrasted the battery study with some of the Mishra group’s other work, which uses machine learning “big data” techniques to sift through thousands of candidates.

“This took more intuition and trial-and-error than other studies we’ve done,” Hartman says. “In principle, you can add a lot of fluoride ions to conventional electrodes to store a lot of charge, but in practice, these theoretical capacities are hard to manage. When we add in fluoride to conventional electrodes, they swell and shrink dramatically as it charges and discharges, and that can lead to cracking and loss of electrical contact.”

Minimizing this volume and shape change is essential to create a durable fluoride battery.

“In these layered electride materials, we predict that adding and removing the fluoride ions would cause significantly smaller structural changes, thus helping achieve a longer cycling life,” Hartman says.

Mishra’s lab is looking to collaborate with researchers who can synthesize the promising electrides identified in this study and test them in prototype batteries.

The study appears in the Journal of Materials Chemistry.