A pneumatic, shape-changing soft robot can navigate its environment without requiring a tether to a stationary power source, report researchers.

It’s like balloon art on steroids.

It’s also a major step in the effort to bring soft robots to human environments, where their characteristics are uniquely suited for interaction with and around people.

“…the robot is actually a collective of individual robotic rollers, which work together to move the robot and change its shape.”

“The main challenge that we’re trying to address is to make a human-scale soft robot,” says mechanical engineering professor Elliot Hawkes of the University of California, Santa Barbara. The work appears in the journal Science Robotics.

Most soft robots to date tend to be small, and often tether to the wall for power or compressed air, he explains. But what if they could create a soft robot large enough and strong enough to perform human-scale interactions and independent enough to navigate diverse, unstructured environments, such as disaster zones?

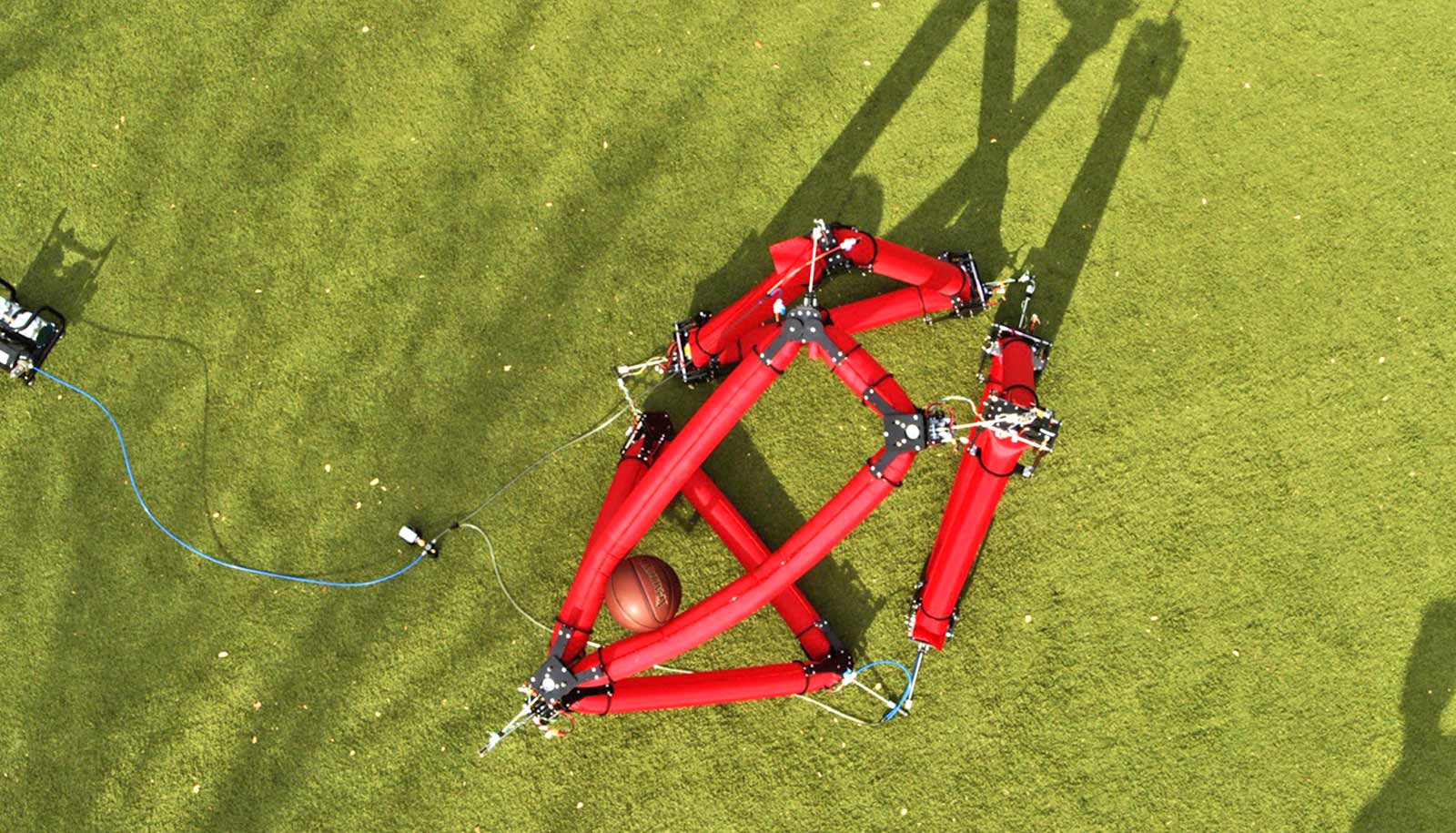

Enter the isoperimetric soft robot, a roughly four-foot-tall pneumatic robot that can move by deforming its soft, air-filled fabric tubes—while keeping its perimeter constant.

“The idea is that you can change the shape of the soft robot by using simple motors that drive along the tubes, instead of using the slow, inefficient pumps that are normally used,” says Hawkes, who conducted research for this paper while at Stanford University.

“The casual description of this robot that I give to people is Baymax from the movie Big Hero 6 mixed with Transformers. In other words, a soft, human-safe robot mixed with robots that can dramatically change their shape,” says Nathan Usevitch, a graduate student in mechanical engineering at Stanford.

Three kinds of robotics in one

The isoperimetric robot is actually a combination of concepts from three distinct robotic areas—soft robotics, truss robots, and collective robots—that together create new capabilities. The soft fabric tubes allow the robot to traverse irregular surfaces and deform as needed, and are light while being strong. The motors also can connect to each other via three-degree-of-freedom universal joints to create truss-like structures that can support weight and allow locomotion in three dimensions. And the motor “nodes” that allow the tubes to bend are themselves small, simple collective robots that together roll along the fabric tube and pinch to form joints of varying angles.

Perhaps the most notable thing about the robot is that it doesn’t require inflation and deflation to move, doing away with the need for a connection to an external, stationary source of air or an unwieldy, bulky onboard pump. The motors are powered by small batteries.

“We were looking at ways to make it untethered, and we realized that we didn’t need to pump air in and out; what we really needed to do was to move the air around,” Hawkes says. This was, in fact, one of the group’s major design challenges.

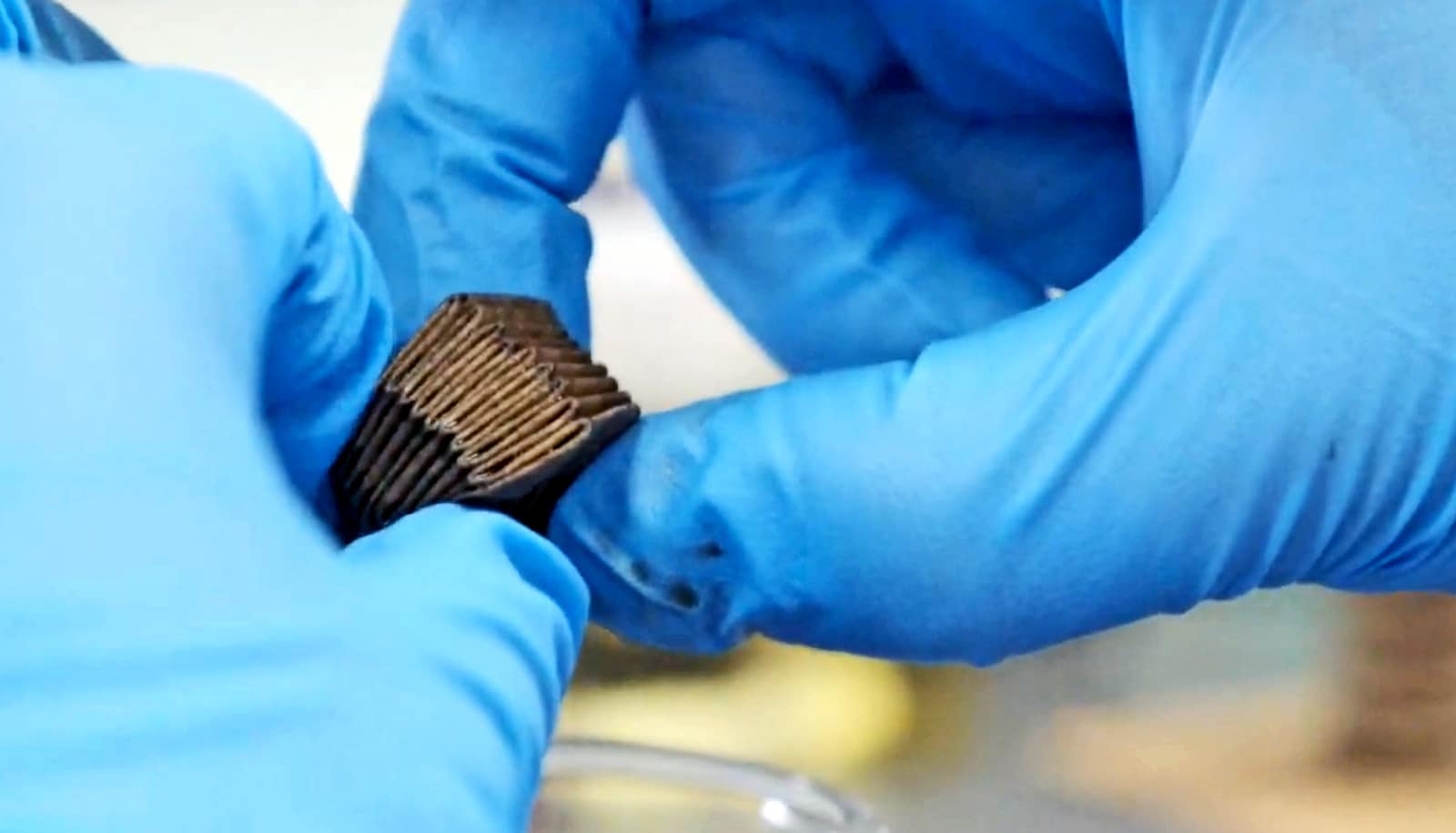

“It turns out that when you have air, even at relatively low pressure, there are huge forces that it applies,” he says, so much of the engineering actually went into creating the nodes that roll along the tube and pinch to create joints. The advantage here, Hawkes adds, is that the robot’s operation is quicker and more seamless than it would be if it had to inflate and deflate in the process.

“What’s exciting to me is that the robot is actually a collective of individual robotic rollers, which work together to move the robot and change its shape,” says Mac Schwager, assistant professor of aeronautics and astronautics and Stanford and coauthor of the paper. “This helps make it an adaptable and robust system.”

What could this sort of soft robot do?

The researchers envision many uses for this type of robot. In a collapsed building scenario, for instance, it could crawl flat into tight spaces and reconfigure into a three-dimensional truss to create space and support weight. For planetary exploration, it packs light and can navigate uncertain terrain. It can pick up and even manipulate loads, and its soft nature allows it to work alongside humans. Its simple, modular construction allows students and other robot-builders to create a variety of their own robots in different shapes for diverse purposes.

Taken together, the robot’s size, freedom of movement, strength, and utility in real-world scenarios represent the type of focus that Hawkes and his group think will be beneficial. Soft robot research is new and exciting, Hawkes says, and it’s taking off.

“But as a field, we need to think critically about what contributions each research project offers, what problems it solves, or how it advances the field,” he says, “as opposed to just making another cool gizmo.”

Other contributors to the work are from Stanford.

Source: UC Santa Barbara, Stanford