Highly absorbent materials called metal-organic frameworks can extract drinkable water out of thin air, research finds.

The discovery could potentially lead to technologies that supply potable water to the driest areas on the planet. For many of the world’s poor, one of the greatest environmental threats to health remains lack of access to safe water.

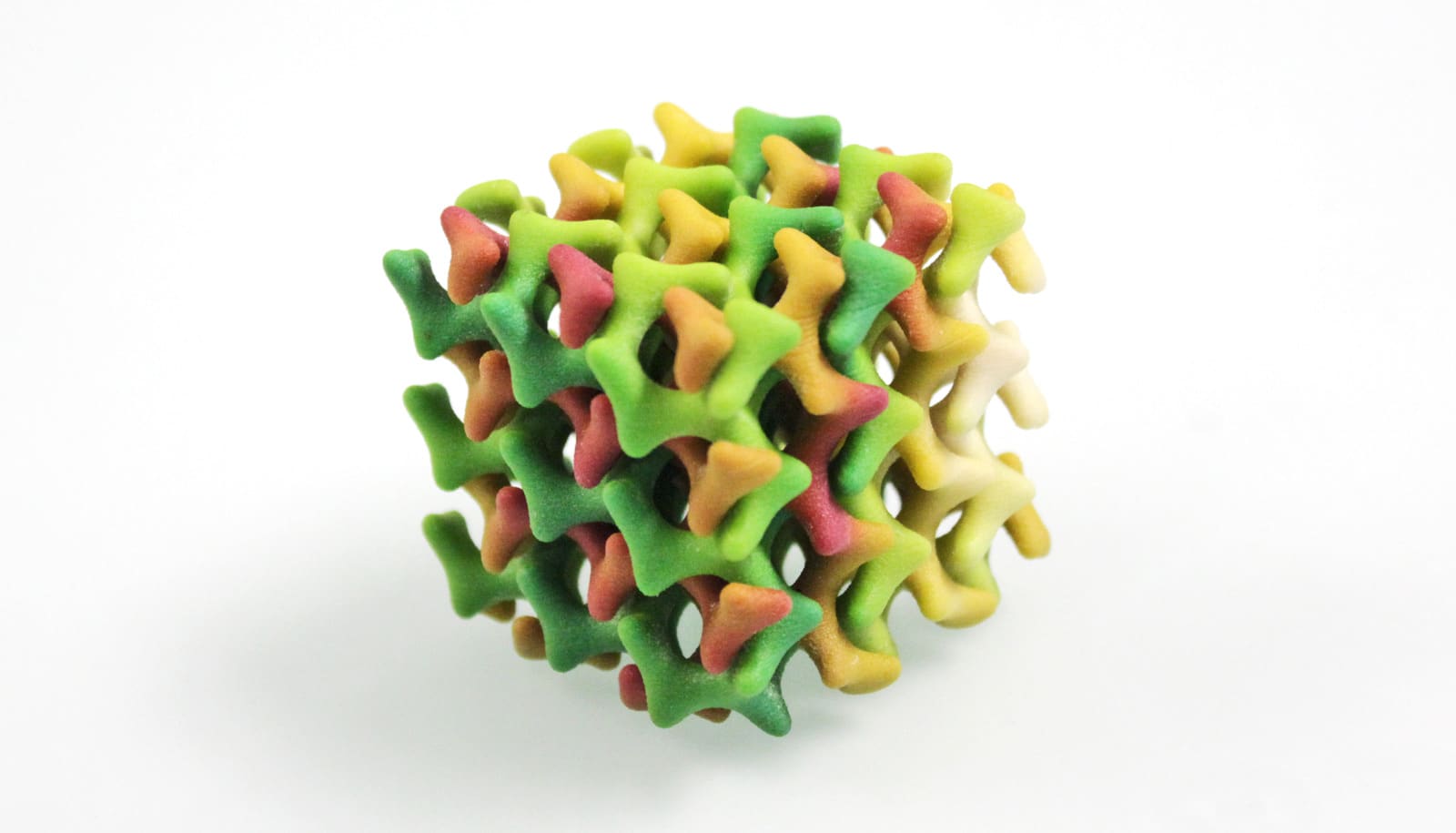

The new research leverages metal-organic frameworks (MOFs), materials with the largest known surface areas per gram. A single gram of the MOF can soak up a football field’s worth of material, when the material is in a single layer across the field.

The sponge-like crystals can capture, store, and release chemical compounds—like water—and the large surface area offers more space for chemical reactions and adsorption of molecules, the researchers say.

MOFs have shown promise for water harvesting, but researchers have done little to determine the best properties for fast and efficient production of water.

“Initial experiments have proved that the concept can work,” says Zhiyong Xia from Johns Hopkins Applied Physics Laboratory. “But the problem has been capacity.

“Other research teams have been able to produce as much as about 1.3 liters of water per day per kilogram of sorbent under arid conditions—enough only for one person. To create an optimal water-harvesting device requires a better understanding of the structure property relationship controlling absorption and delivery.”

Xia and his team studied a series of MOFs—unraveling the fundamental material properties that govern the kinetics of water sequestration in this class of materials as well as investigating how much water they can absorb. They also explored the potential impact of temperature, humidity, and powder bed thickness on the adsorption-desorption process to see which one achieved optimal operational parameters.

“We identified a MOF that could produce 8.66 liters of water per day per kilogram of MOF under ideal conditions, an extraordinary finding.” Xia says. “This will help us deepen our understanding of these materials and guide the discovery of next-generation water-harvesting methods.”

The researchers are now exploring other MOFs with low relative humidity influx points, high surface areas, and polar functional properties to see how they perform in very dry environments. They are also exploring different configurations of MOFs to determine which allow for optimal absorption.

The researchers drew on APL’s ongoing efforts in water purification methods. APL has developed a new way to remove highly toxic perfluoroalkyl substances—an ever-expanding group of manufactured chemicals widely used to make various types of everyday products—from drinking water. A separate effort yielded a cost-effective method to remove toxic heavy metal ions from drinking water.

“Our scientists’ and engineers’ collective strengths and expertise in materials and chemistry have positioned APL to make extraordinary impact and invent the future of clean drinking water for deployed warfighters, as well as for citizens around the world,” says Ally Bissing-Gibson, APL’s Biological and Chemical Sciences program manager. “We look forward to saving the planet, one drop at a time.”

Source: Johns Hopkins University