A new robotic gripper can alter its grip depending on what it’s holding.

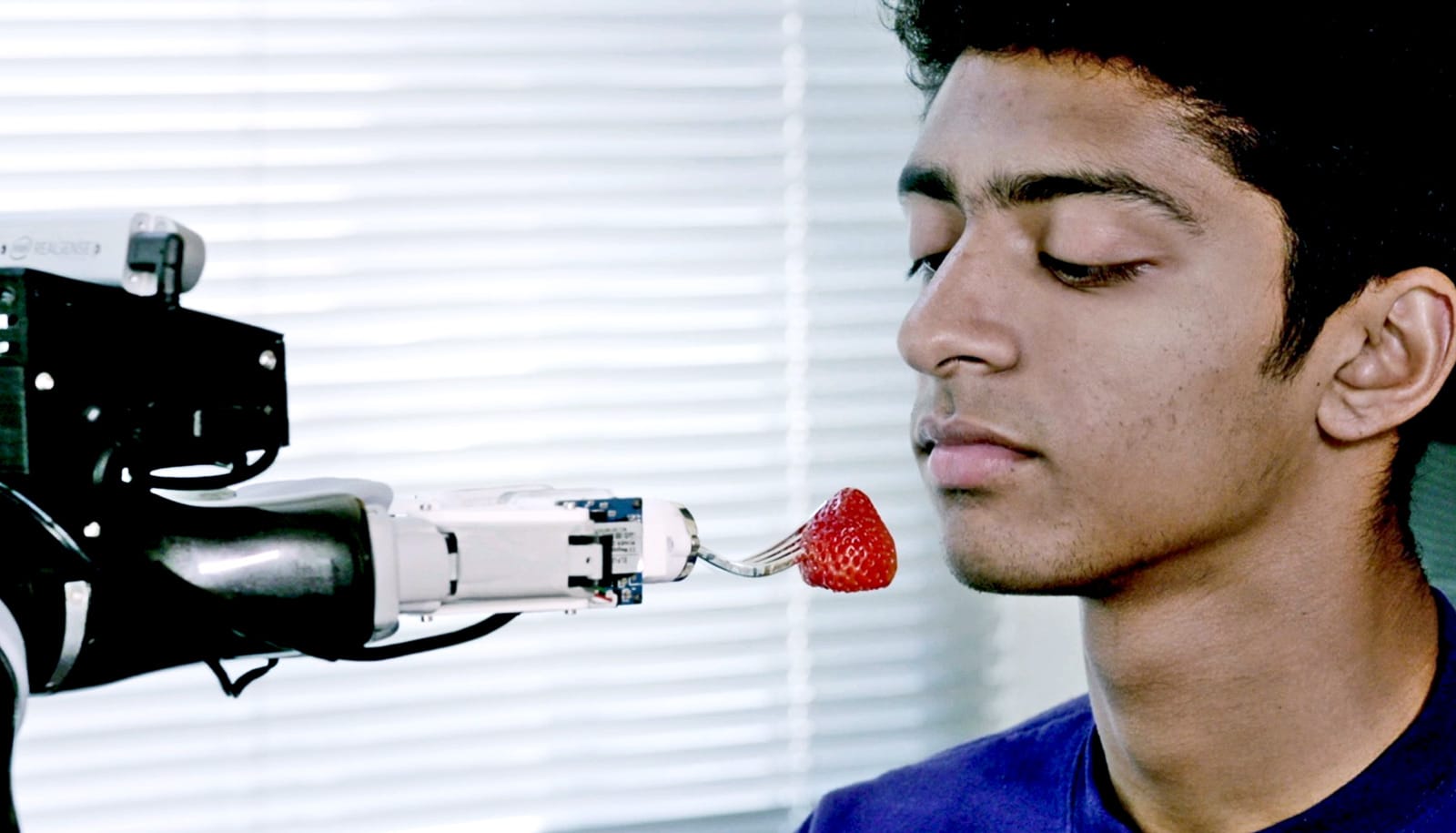

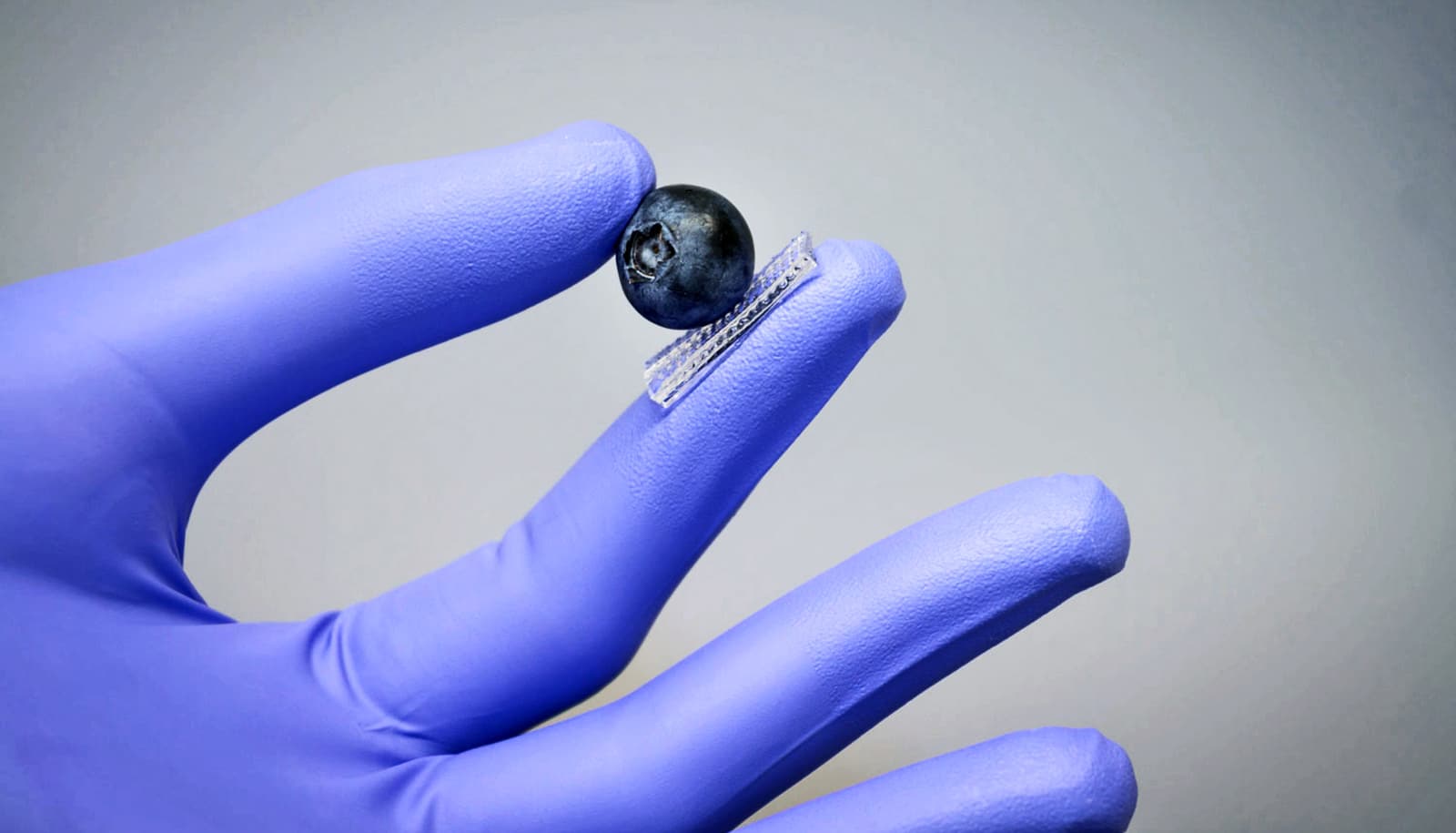

Human hands have remarkable skills that allow manipulation of a range of objects. We can pick up an egg or a strawberry without smashing it. We can hammer a nail. One reason our hands can perform such a variety of tasks has to do with our ability to alter the firmness of our grip.

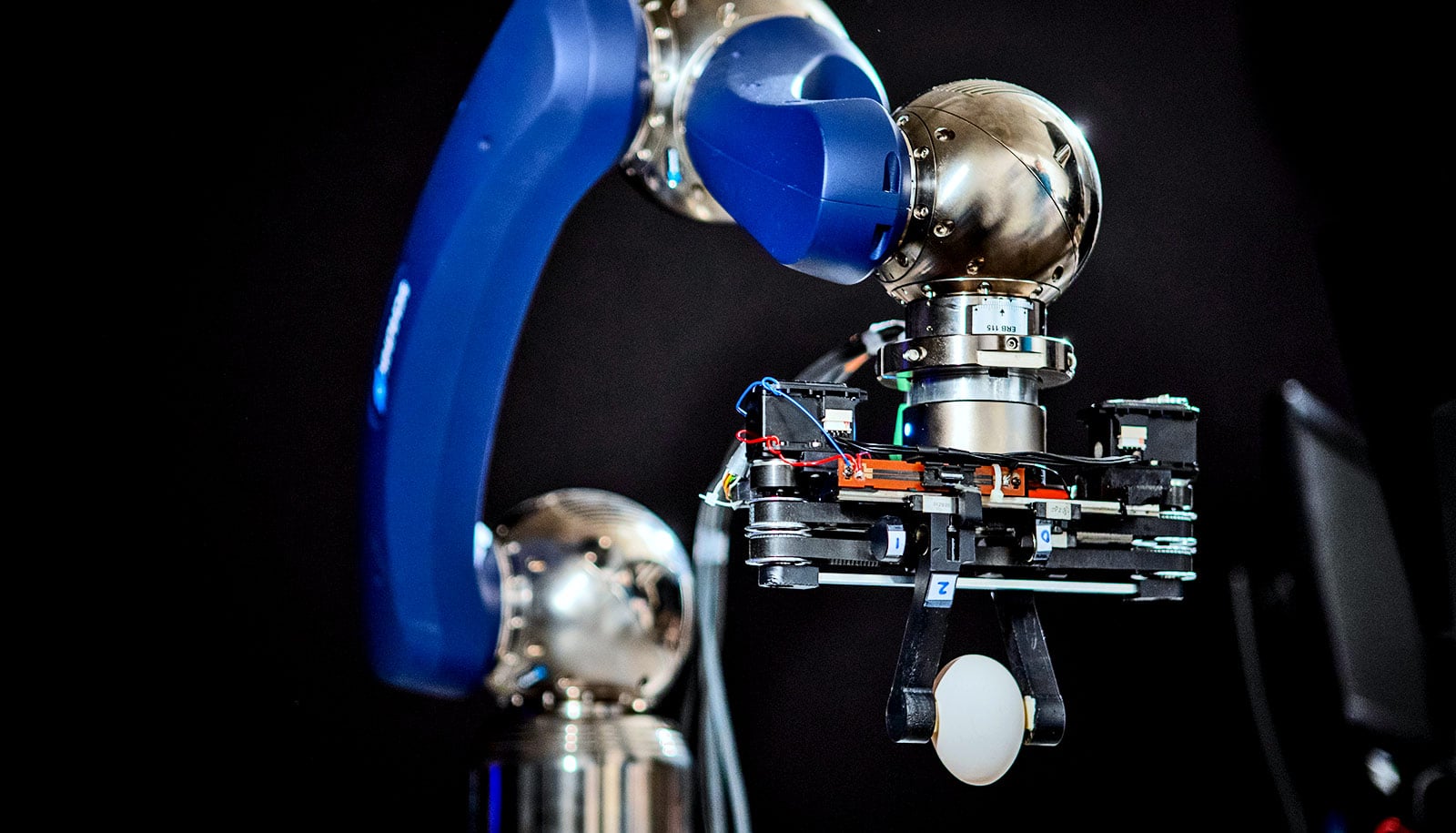

Researchers designed the new two-fingered robotic hand to do the same thing.

The design of the robotic hand allows it to absorb energy from impacts during collisions, researcher say. This prevents whatever the robot is holding from breaking, and also makes it safer for people to work with and near the machines.

Such grippers would be a valuable asset for human-robot partnership in assembly lines in the automotive, electronic packaging, and other industries, says Ehsan Esfahani, associate professor of mechanical and aerospace engineering in the University at Buffalo School of Engineering and Applied Sciences.

“Our robotic gripper mimics the human hand’s ability to adjust the stiffness of the grip. These grippers are designed for collaborative robots that work together with people. They’re going to be helpers, so they need to be safe, and variable stiffness grippers help to achieve that goal.”

Magnets are the secret behind the robotic gripper’s versatility, Esfahani says. Instead of having two fingers fixed in place, each of the gripper’s fingers has a magnetic base that sits between two neodymium magnets that repulse, or push against, the finger.

The air gap between the magnets acts like a spring, creating a little give when the hand picks up an object or collides with an external force. User cans also increase or decrease the space between the magnets to adjust the stiffness of the grip.

In one test, the engineers placed a short stick of spaghetti lengthwise between the fingers of the robotic hand. When the gripper crashed into a fixed object, the device detected the external force, which caused the magnets to adjust their position, temporarily reducing the stiffness of the grip and allowing the gripper to absorb some of the energy from the collision.

The end result? The spaghetti stick stayed in one piece.

It’s possible to attach the gripper to commercially available robot arms already in use in many facilities, Esfahani says. That could lower the cost of adapting the technology for companies interested in improving the safety and capabilities of existing machines.

The study appears in IEEE Transactions on Industrial Electronics.

Source: University at Buffalo