Swarms of “micro-bristle-bots” could one day work together to sense environmental changes, move materials, or perhaps one day repair injuries inside the human body.

This new type of tiny 3D-printed robot moves by harnessing vibration from piezoelectric actuators, ultrasound sources, or even tiny speakers.

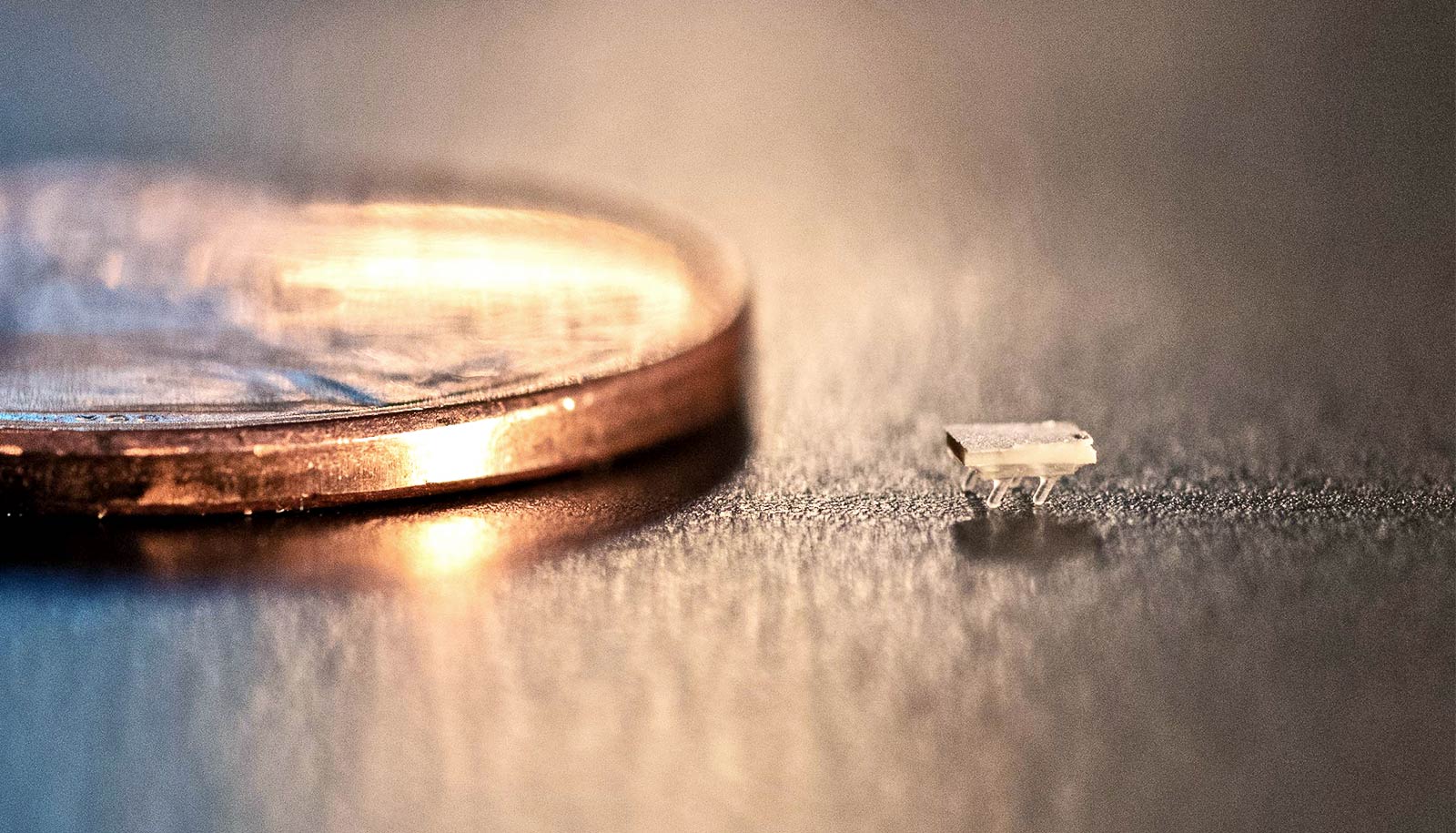

The prototype robots respond to different vibration frequencies depending on their configurations, allowing researchers to control individual bots by adjusting the vibration. Approximately two millimeters long—about the size of the world’s smallest ant—the bots can cover four times their own length in a second despite the physical limitations of their small size.

“We are working to make the technology robust, and we have a lot of potential applications in mind,” says Azadeh Ansari, an assistant professor in the School of Electrical and Computer Engineering at the Georgia Institute of Technology.

How does the micro-bristle-bot work?

The micro-bristle-bots consist of a piezoelectric actuator glued onto a polymer body that researchers 3D-printed using two-photon polymerization lithography (TPP). The actuator generates vibration and is powered externally because no batteries are small enough to fit onto the bot. The vibrations can also come from a piezoelectric shaker beneath the surface on which the robots move, from an ultrasound/sonar source, or even from a tiny acoustic speaker.

The vibrations move the springy legs up and down, propelling the micro-bot forward. Each robot can be designed to respond to different vibration frequencies depending on leg size, diameter, design, and overall geometry. The amplitude of the vibrations controls the speed at which the micro-bots move.

“As the micro-bristle-bots move up and down, the vertical motion is translated into a directional movement by optimizing the design of the legs, which look like bristles,” explains Ansari. “The legs of the micro-robot are designed with specific angles that allow them to bend and move in one direction in resonant response to the vibration.”

The micro-bristle-bots are made in a 3D printer using the TPP process, a technique that polymerizes a monomer resin material. Once the portion of the resin block struck by the ultraviolet light has been chemically developed, the remainder can be washed away, leaving the desired robotic structure.

“It’s writing rather than traditional lithography,” Ansari explains. “You are left with the structure that you write with a laser on the resin material. The process now takes quite a while, so we are looking at ways to scale it up to make hundreds or thousands of micro-bots at a time.”

Some of the robots have four legs, while others have six. First author DeaGyu Kim made hundreds of the tiny structures to determine the ideal configuration.

Skittering and dancing

The piezoelectric actuators, which use the material lead zirconate titanate (PZT), vibrate when electric voltage is applied to them. In reverse, they can generate a voltage, when researchers vibrate them, a capability the micro-bristle-bots could use to power up onboard sensors when external vibrations actuate them.

Ansari and her team are working to add steering capability to the robots by joining two slightly different micro-bristle-bots together. Because each of the joined micro-bots would respond to different vibration frequencies, the combination could be steered by varying the frequencies and amplitudes. “Once you have a fully steerable micro-robot, you can imagine doing a lot of interesting things,” she says.

Other researchers have worked on micro-robots that use magnetic fields to produce movement, Ansari notes. While that is useful for moving entire swarms at once, researchers cannot easily use magnetic forces to address individual robots within a swarm. The micro-bristle-bots Ansari and her team created are believed to be the smallest robots powered by vibration.

The micro-bristle-bots are approximately two millimeters in length, 1.8 millimeters wide and 0.8 millimeters thick, and weigh about five milligrams. The 3D printer can produce smaller robots, but with a reduced mass, the adhesion forces between the tiny devices and a surface can get very large. Sometimes, the micro-bots cannot be separated from the tweezers used to pick them up.

Ansari and her team have built a “playground” in which multiple micro-bots can move around as the researchers learn more about what they can do. They are also interested in developing micro-bots that can jump and swim.

“We can look at the collective behavior of ants, for example, and apply what we learn from them to our little robots,” she adds. “These micro-bristle-bots walk nicely in a laboratory environment, but there is a lot more we will have to do before they can go out into the outside world.”

The Journal of Micromechanics and Microengineering has accepted a paper describing the micro-bristle-bots for publication.

The researchers performed the micro-bot fabrication at the Georgia Tech Institute for Electronics and Nanotechnology, a member of the National Nanotechnology Coordinated Infrastructure, which the National Science Foundation supports. Support for the research came from a seed grant from Georgia Tech’s Institute for Electronics and Nanotechnology.

Source: Georgia Tech