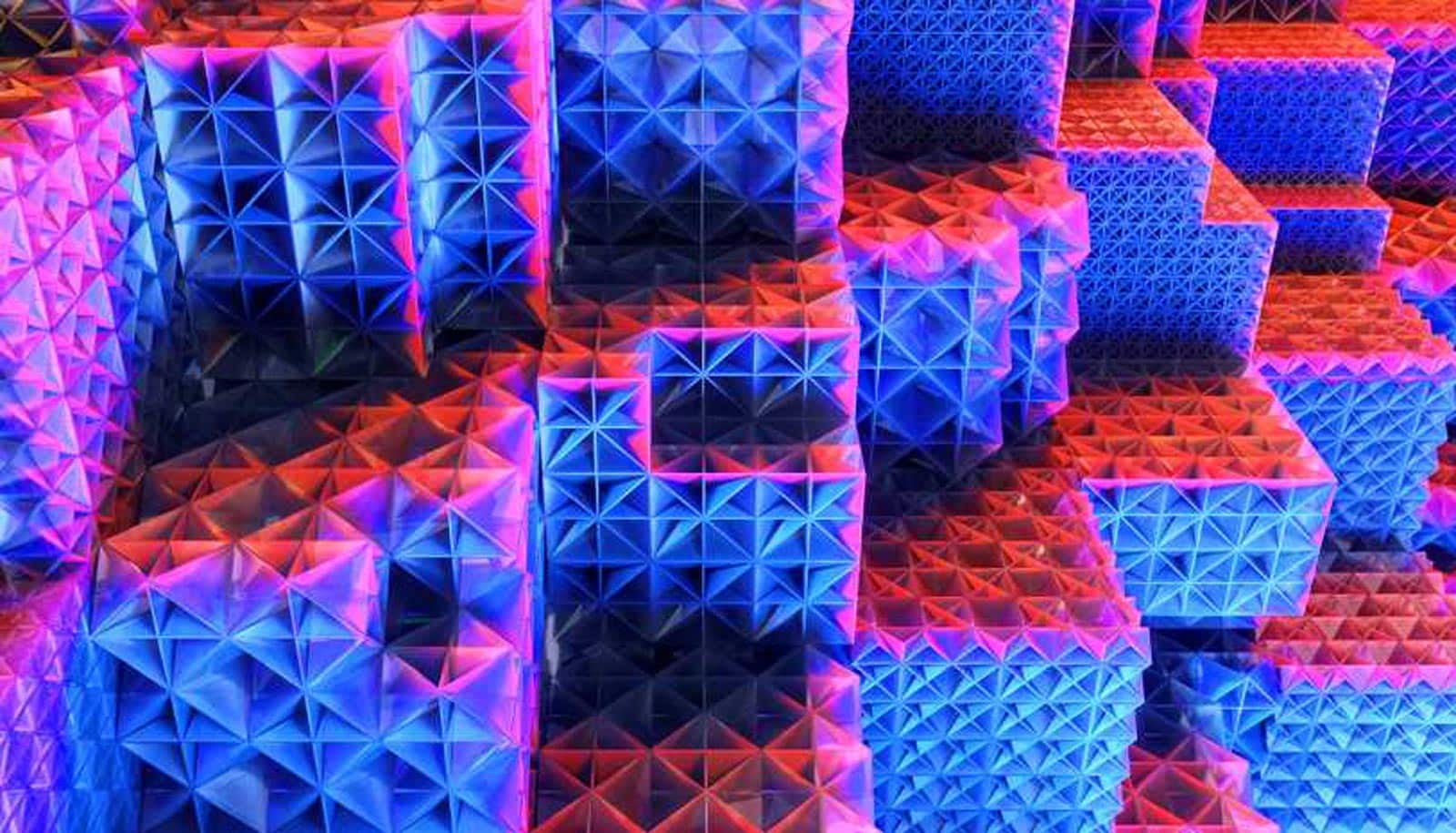

Researchers have developed and manufactured a family of structures that maximize the stiffness of porous lightweight materials. It’s practically impossible to develop stiffer designs for their given weight.

3D printing and other additive production techniques make it possible to manufacture materials with internal structures of previously unimaginable complexity. This is interesting for lightweight construction, too, as it enables the development of robust-as-possible materials with the highest possible share of interior voids, which make the materials as light as possible. Achieving this requires intelligent organization of internal structures for maximum efficiency.

Researchers at ETH Zurich and MIT have developed and fabricated material architectures that are equally strong in all three dimensions, and that are simultaneously extremely stiff.

It’s possible to determine mathematically just how stiff materials with internal voids can theoretically become, and these structures have been shown to come extremely close to this theoretical maximum stiffness.

A characteristic feature of the design is that the stiffness in the material’s interior is achieved through plate-lattices rather than trusses.

“The truss principle is very old; it has long been used for half-timbered houses, steel bridges, and steel towers, such as the Eiffel Tower,” says team leader Dirk Mohr, professor of computational modeling of materials in manufacturing at ETH Zurich.

“We can see through truss lattices, so they are often perceived as ideal lightweight structures. However, using computer calculations, theory, and experimental measurements, we have now established a new family of plate-lattice structures that are up to three times stiffer than truss-lattices of the same weight and volume.

“And it is not just the stiffness (resistance to elastic deformation) of these structures that approaches theoretical maximum values: their strength (resistance to irreversible deformation) does, too.”

The ETH researchers initially developed these lattices on the computer, calculating their properties in the process. Then they produced them at the micrometer scale from plastic through 3D printing. Mohr emphasizes, however, that the advantages of this design are universally applicable—for all constituent materials and also on all length scales, from the very small (nanometer-sized) to the very large.

Right now, manufacturing with 3D printing is still relatively expensive. “If these kinds of lattices were to be additively manufactured from stainless steel today, they would cost as much per gram as silver,” says Mohr. “But the breakthrough will come when additive manufacturing technologies are ready for mass production. Lightweight construction, the current cost of which limits its practical use to aircraft manufacturing and space applications, could then also be used for a wide array of applications in which weight plays a role.”

In addition to making structures lighter, the numerous voids also reduce the amount of raw materials, and so also the material costs.

There’s no limit to the potential applications, Mohr says. Medical implants, laptop casings, and ultra-light vehicle structures are just three of many possible examples. “When the time is right, as soon as lightweight materials are being manufactured on a large scale,” Mohr says, “these periodic plate lattices will be the design of choice.”

The work appears in Advanced Materials.

Source: ETH Zurich