The first 3D image of a microscopic crack propagating through a metal that hydrogen damaged could help prevent the failure of all sorts of things, like bridges and dental implants, researchers say.

“For the first time we were able to catch the crack red-handed,” says Michael J. Demkowicz, associate professor of materials science and engineering at Texas A&M University.

“It’s much better than arriving at the crime scene after the fact.”

Previously, the only way to analyze such a metal failure was to look at the separated pieces of a completely fractured component, which requires a certain amount of guesswork. The new research shows what is happening at the crack tip as a part begins to fracture.

“It’s much better than arriving at the crime scene after the fact,” Demkowicz says.

Hydrogen to blame

Using the 3D image, researchers identified 10 microscopic structures that make metals stronger and less susceptible to a key environmental factor—the hydrogen around us—that can damage them.

The researchers conducted the work, which appears in Nature Communications, using tools at Argonne National Laboratory’s Advanced Photon Source (APS).

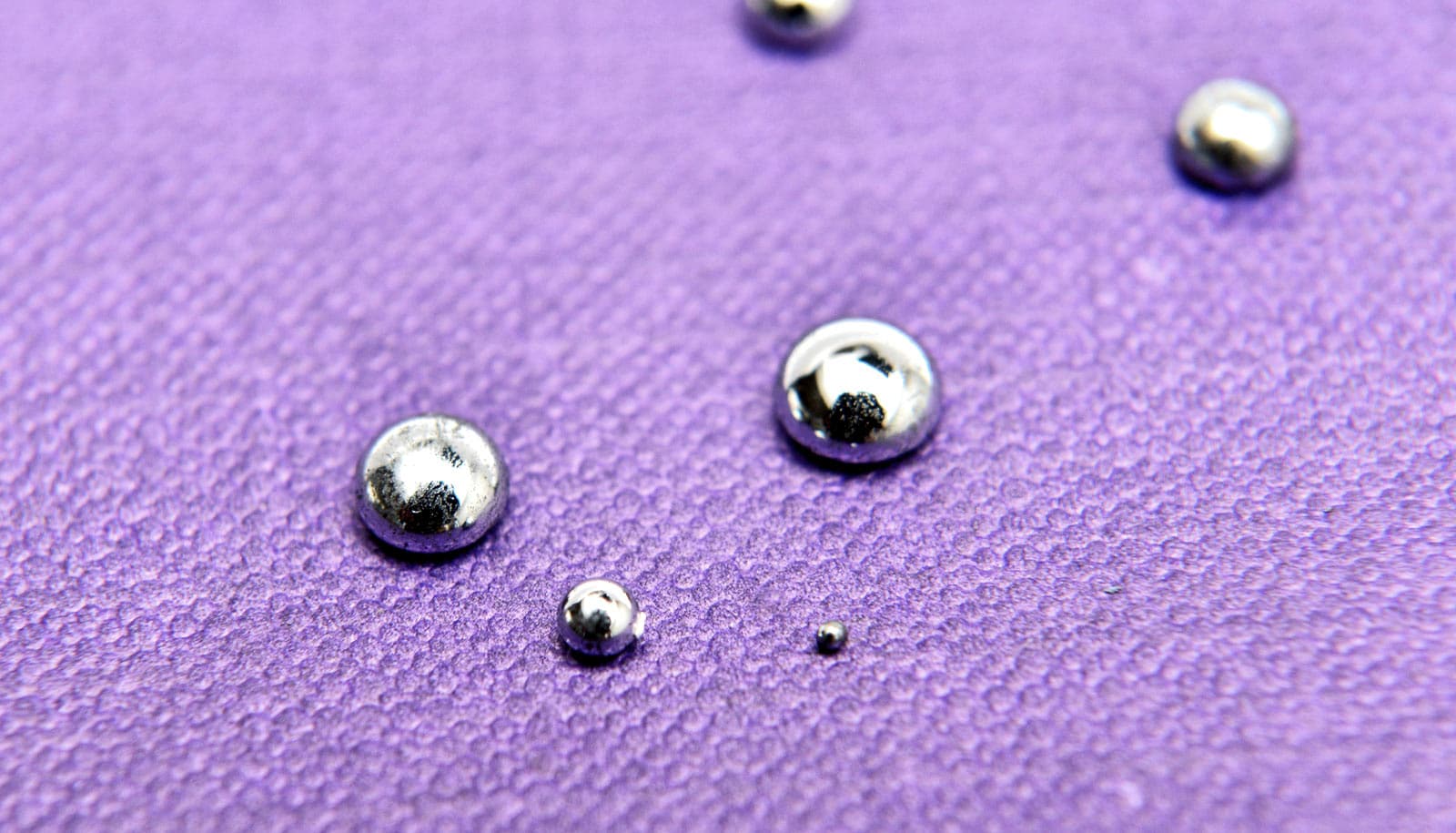

Metals are in any number of structures and devices, but the ubiquitous hydrogen around us, mostly from water, can negatively affect them.

“Hydrogen gets into the metal and causes it to fracture unexpectedly in a process called hydrogen embrittlement,” says first author John P. Hanson, a reactor engineer at Oklo.

A prominent example of this is what happened to the Bay Bridge in San Francisco. As the bridge was being constructed in 2013, engineers discovered that 32 of the 96 huge bolts key to the structure had cracked due to hydrogen embrittlement. Engineers caught the problem early so there was no catastrophe, but it delayed the opening of the bridge by a few years.

“…engineers have to overdesign with additional material to cover any sudden failure and that costs a lot.”

Scientists have studied hydrogen embrittlement for over 150 years, but it remains difficult to predict.

“That’s largely because we don’t have a complete understanding of the mechanisms behind it,” says Hanson, who conducted the work while earning his doctorate at Massachusetts Institute of Technology.

“As a result, engineers have to overdesign with additional material to cover any sudden failure and that costs a lot,” says coauthor Peter Kenesei of Argonne, who operates the instruments researchers used in the work. “So a better understanding of this behavior could have a huge economic impact.”

“You can make progress on old problems when you have new tools,” Demkowicz says.

The researchers used two different synchrotron tools, high-energy diffraction microscopy and X-ray absorption tomography, to analyze the microscopic structure of a crack in a superalloy of nickel.

The new study is the first time researchers not involved in the microscopy technique’s development used it. The combined experimental tool and analysis software are unique in the world.

Staying strong

A metal is composed of microscopic crystals, or grains. In nickel superalloys, the fractures that hydrogen embrittlement bring on travel along the boundaries between those grains.

The unique tools at the APS beamline 1-ID allow researchers to not only look at the grain orientations around a crack in progress, but also the grain boundaries, Hanson says.

From those observations, the team identified 10 grain boundaries that are more resistant to cracks.

“We were able to show not only which grain boundaries are stronger, but exactly what it is about them that improves their performance,” says Hanson, adding that this could ultimately allow engineers to build stronger metals by designing them with those characteristics.

In the nearer term, researchers could use the tools to image the microstructure of existing metal components to better predict their susceptibility to failure. Kenesei notes that the tools are already being used this way to study other engineering materials, such as those related to airplanes, batteries, and nuclear reactors.

The study took eight years to complete, primarily because it involved huge amounts of data that were difficult to analyze. The raw data for the work would fill almost 400 DVDs, researchers say. And the data looks nothing like a 3D model of the material.

“It’s highly encrypted in the form of streaks and dots, or diffraction patterns, that must be analyzed by a supercomputer,” says Robert M. Suter of Carnegie Mellon University.

Coauthors are from Carnegie Mellon, Johns Hopkins University, MIT, and Lawrence Livermore National Laboratory. The BP-MIT Materials and Corrosion Center, the National Science Foundation, and the US Department of Energy supported the work.