A flexible material made from multiple layers of chitin from crab shells and cellulose from trees could one day replace plastic packaging film.

“The main benchmark that we compare it to is PET, or polyethylene terephthalate, one of the most common petroleum-based materials in the transparent packaging you see in vending machines and soft drink bottles,” says J. Carson Meredith, a professor in Georgia Tech’s School of Chemical and Biomolecular Engineering.

“Our material showed up to a 67 percent reduction in oxygen permeability over some forms of PET, which means it could in theory keep foods fresher longer.”

Cellulose and chitin

Cellulose, which comes from plants, is the planet’s most common natural biopolymer, followed next by chitin, which comes from shellfish, insects, and fungi.

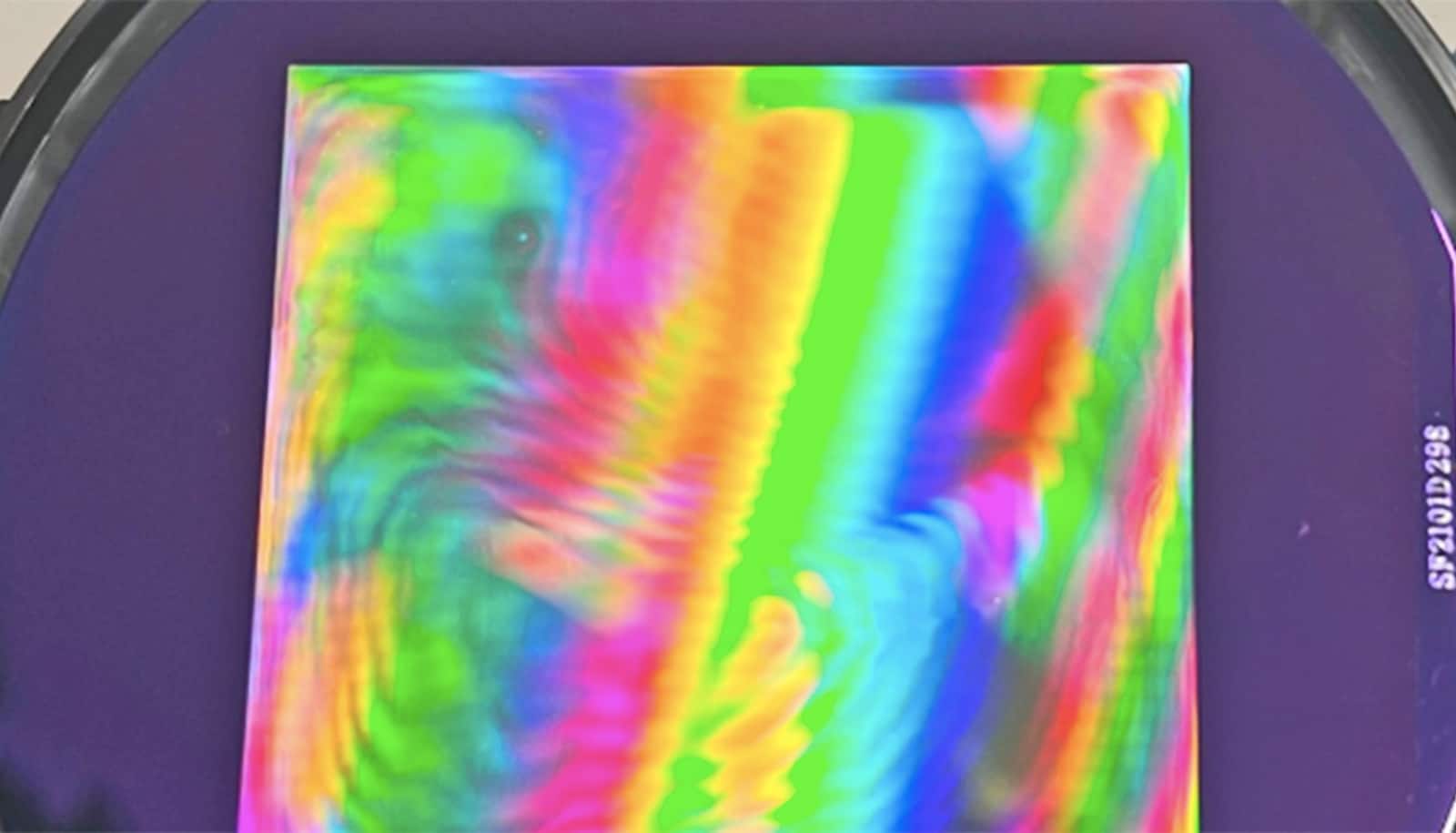

Researchers devised a method to create a film by suspending cellulose and chitin nanofibers in water and spraying them onto a surface in alternating layers. Once fully dried, the material is flexible, strong, transparent, and compostable.

“We had been looking at cellulose nanocrystals for several years and exploring ways to improve those for use in lightweight composites as well as food packaging, because of the huge market opportunity for renewable and compostable packaging, and how important food packaging overall is going to be as the population continues to grow,” Meredith says.

Alternating layers

The team had been looking into chitin for an unrelated reason when they wondered if it might be useful in food packaging.

“We recognized that because the chitin nanofibers are positively charged, and the cellulose nanocrystals are negatively charged, they might work well as alternating layers in coatings because they would form a nice interface between them,” Meredith says.

Packaging meant to preserve food needs to prevent oxygen from passing through. Part of the reason the new material improves upon conventional plastic packaging as a gas barrier is because of the crystalline structure of the film.

“It’s difficult for a gas molecule to penetrate a solid crystal, because it has to disrupt the crystal structure,” Meredith says. “Something like PET on the other hand has a significant amount of amorphous or non-crystalline content, so there are more paths easier for a small gas molecule to find its way through.”

Biomaterial made of crabs could cut plastic pollution

Environmentalists have long looked for renewable ways to replace petroleum-based materials in consumer products. With the amount of cellulose already produced and a ready supply of chitin-rich byproducts left over from the shellfish food industry, there’s likely more than enough material available to make the new films a viable flexible-packaging alternative, Meredith says.

Still, there’s more work to be done. To make the new material eventually competitive with flexible packaging film on cost, a manufacturing process that maximizes economy of scale will be necessary.

Plastic bits in barnacles threaten food chain

Additionally, while industrial processes to mass produce cellulose are mature, methods to produce chitin are still in their infancy, Meredith says. And, more research is also needed to improve the material’s ability to block water vapor.

The Georgia Tech Renewable Bioproducts Institute and the Georgia Research Alliance funded the work, which appears in ACS Sustainable Chemistry and Engineering.

Source: Georgia Tech