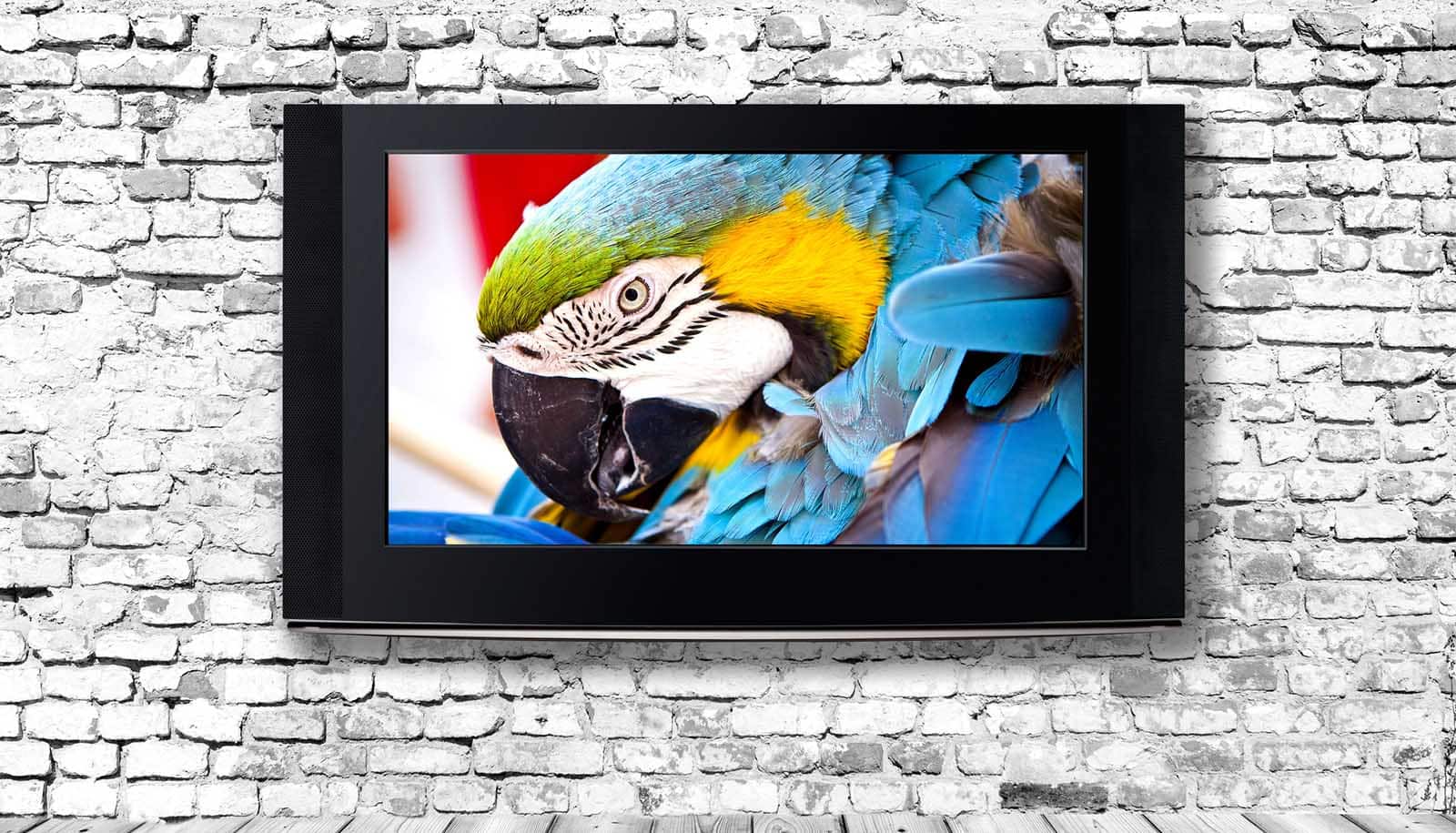

Tiny crystals called quantum dots are used in LCD TVs to enhance color and image quality. A few years ago, scientists discovered a new type of crystal called nanoplatelets.

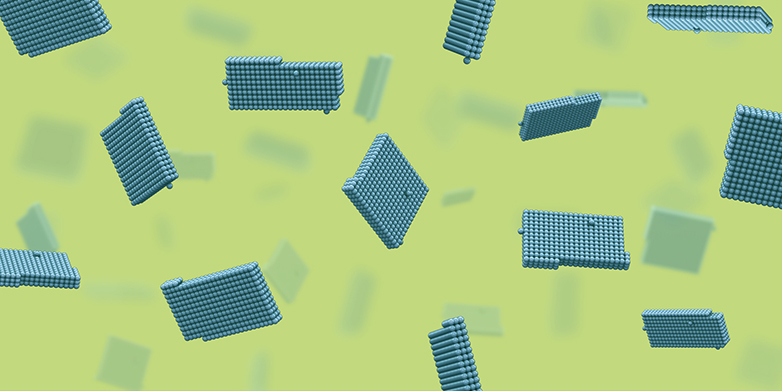

Like quantum dots, these two-dimensional structures are just a few nanometers in size, but have a more uniform flat, rectangular shape. They are extremely thin, often just the width of a few atomic layers, giving the platelets one of their most striking properties—their extremely pure color.

Now scientists have solved the mystery of out how these platelets form—and then created them in the lab using pyrite.

“We now know that there’s no magic involved in producing nanoplatelets, just science,” says David Norris, a materials engineering professor at ETH Zurich.

In a study just published in the scientific journal Nature Materials, Norris and colleagues show how cadmium selenide nanoplatelets take on their particular flat shape.

How the platelets grow

Researchers had previously assumed that this highly precise form required a type of template. Scientists suspected that a mixture of special compounds and solvents produced a template in which these flat nanocrystals then formed.

However, Norris and his colleagues found no evidence that such shape templates had any role. On the contrary, they found that the platelets can grow through the simple melting of the raw substances cadmium carboxylate and selenium, without any solvent.

The used that information to develop a theoretical model to simulate the growth of the platelets.

They showed that a crystallized core occurs spontaneously with just a few cadmium and selenium atoms. This crystallized nucleus can dissolve again and reconfigure in a different form. However, once it has exceeded a critical size, it grows to form a platelet.

For energy-related reasons, the flat crystal grows only on its narrow side, up to 1,000 times faster than on its flat side. Growth on the flat side is significantly slower because it would involve more poorly bonded atoms on the surface, requiring energy to stabilize them.

Make them in the lab

Ultimately, the researchers also succeeded in confirming their model experimentally by creating pyrite (FeS2) nanoplatelets in the lab. They produced the platelets exactly according to the model prediction using iron and sulfur ions as base substances.

“It’s very interesting that we were able to produce these crystals for the first time with pyrite,” says Norris. “That showed us that we can expand our research to other materials.”

Cadmium selenide is the most common semiconductor material used in the research of nanocrystals; however, it is highly toxic and thus unsuitable for everyday use. The researchers’ goal is to produce nanoplatelets made from less toxic or non-toxic substances.

Will they replace quantum dots?

Quantum dots are spherical nanocrystals made of a semiconductor material. When these crystals are excited by light, they glow green or red—depending on their size, which is typically between 2 and 10 nanometers. The spherical forms can be produced in a highly controlled manner.

Norris speculates that nanoplatelets may be an interesting alternative to quantum dots as they offer several advantages; for example, they can generate colors such as green better and more brightly.

They also transmit energy more efficiently, which makes them ideal for use in solar cells, and they would also be suitable for lasers.

Unknown features of liquid crystals could improve screens

They have disadvantages, too. Quantum dots, for example, allow infinitely variable color through the formation of varying size crystals. Not so in the case of platelets: due to the stratification of the atomic layers, the color can be changed only incrementally.

Fortunately, this limitation can be mitigated with certain “tricks”: by encapsulation of the platelets in another semiconductor, the wavelength of the light emitted can be tuned more precisely.

How the technology will evolve is unclear. However, the ability to investigate a broad variety of nanoplatelet materials due to this work may provide the semiconductor nanocrystal approach with a new edge.

Source: ETH Zurich