A new kind of ink for 3D printing liquifies when pressed through the nozzle of a 3D printer, but then quickly returns to its original shape, researchers report.

The invention paves the way for personalized biomaterial implants, according to new research.

In the same way that medicine has seen a trend towards precision medicine—where doctors tailor treatment to the genetic make-up of the patient—in recent years, materials scientists have increasingly turned their attention to precision biomaterials. As things stand, however, personalized implants remain a long way off.

“But at the moment, we’re making great progress toward this goal—and learning a lot in the process,” says Mark Tibbitt, a professor of macromolecular engineering in the mechanical and process engineering department at ETH Zurich.

Previously, the fact that researchers had to develop new [A1] inks for the 3D printer for each application held back researchers working in the field of precision biomaterials.

“If someone wanted to replicate part of an eye, for instance, they weren’t able to draw on the work of people who design auricular prostheses,” Tibbitt explains. But now, he and his team have invented a universal carrier ink that “dramatically simplifies” the development of new applications, the researchers write.

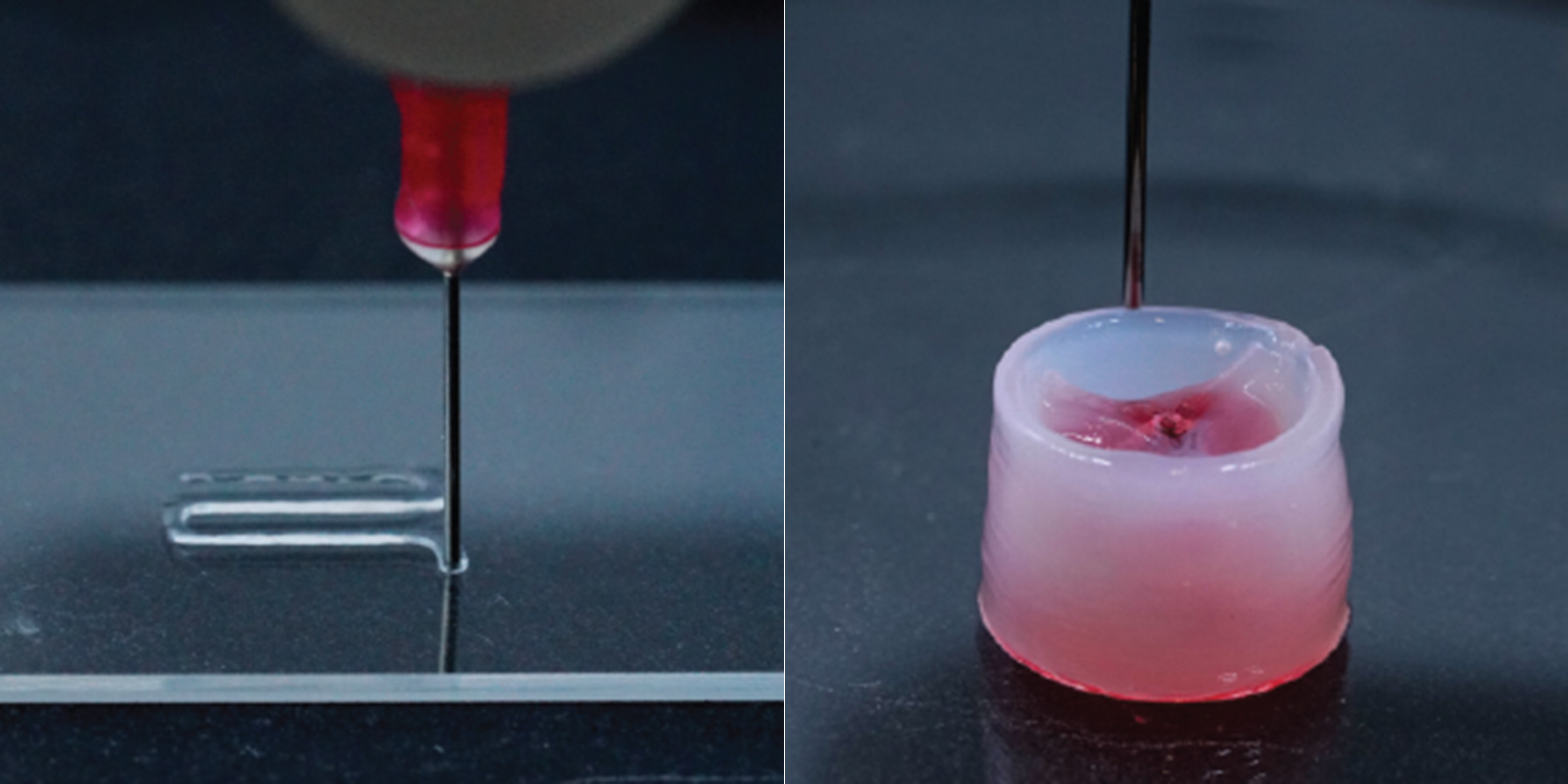

Essentially, 3D printing calls for a solution to a conundrum casually referred to as “the toothpaste problem.” On one hand, toothpaste should not be too viscous as that would make it difficult to squeeze through the narrow opening of the tube; on the other, it can’t be too fluid because it would then immediately drip off the toothbrush.

Similarly, in 3D printing, the carrier ink needs to be able to liquify to flow through the printing nozzle, and then solidify so that the printed structure does not immediately lose its shape.

This is where the universal carrier ink that Tibbitt’s team has developed can help. It consists of cellulose fibers dissolved in water combined with biodegradable polymeric nanoparticles. When no external pressure is exerted, the fibers attach themselves to the particles. This creates a transient network that can be disrupted when subjected to the high shear forces in the printer nozzle—but that quickly reforms after passing through the narrow opening.

In further experiments, Tibbitt and his team added different polymers (such as hyaluronic acid, gelatine, collagen, or fibrinogen) to their new carrier ink. These secondary polymers did not change the ink’s flow behavior through the head of the printer nozzle, but enabled the researchers to solidify the transient network to form the printed structure in a second, subsequent step.

Tibbitt’s team also tested how living cells behave in the carrier ink—and found that the same number of cells survive in the ink as they do outside. Based on the fact that researchers can introduce hydrophobic substances into the nanoparticles—and add hydrophilic substances to the aqueous phase with the cellulose fibers—they demonstrated that their ink is also suitable for the development of novel drug delivery systems.

The research appears in the journal Small.

Source: ETH Zurich