Researchers have created a method for 3D printing plastic objects and sensors that can communicate with other internet-connected devices all on their own.

For example, imagine a bottle of laundry detergent that can sense when you’re running low on soap—and automatically connect to the internet to place an order for more.

With CAD models that the team is making available to the public, 3D printing enthusiasts will be able to create objects out of commercially available plastics that can wirelessly communicate with other smart devices.

That could include a battery-free slider that controls music volume, a button that automatically orders more cornflakes from Amazon, or a water sensor that sends an alarm to your phone when it detects a leak.

How it works

“Our goal was to create something that just comes out of your 3D printer at home and can send useful information to other devices,” says Vikram Iyer, co-lead author of a paper describing the technique and an electrical engineering doctoral student at the University of Washington.

“But the big challenge is how do you communicate wirelessly with Wi-Fi using only plastic? That’s something that no one has been able to do before.”

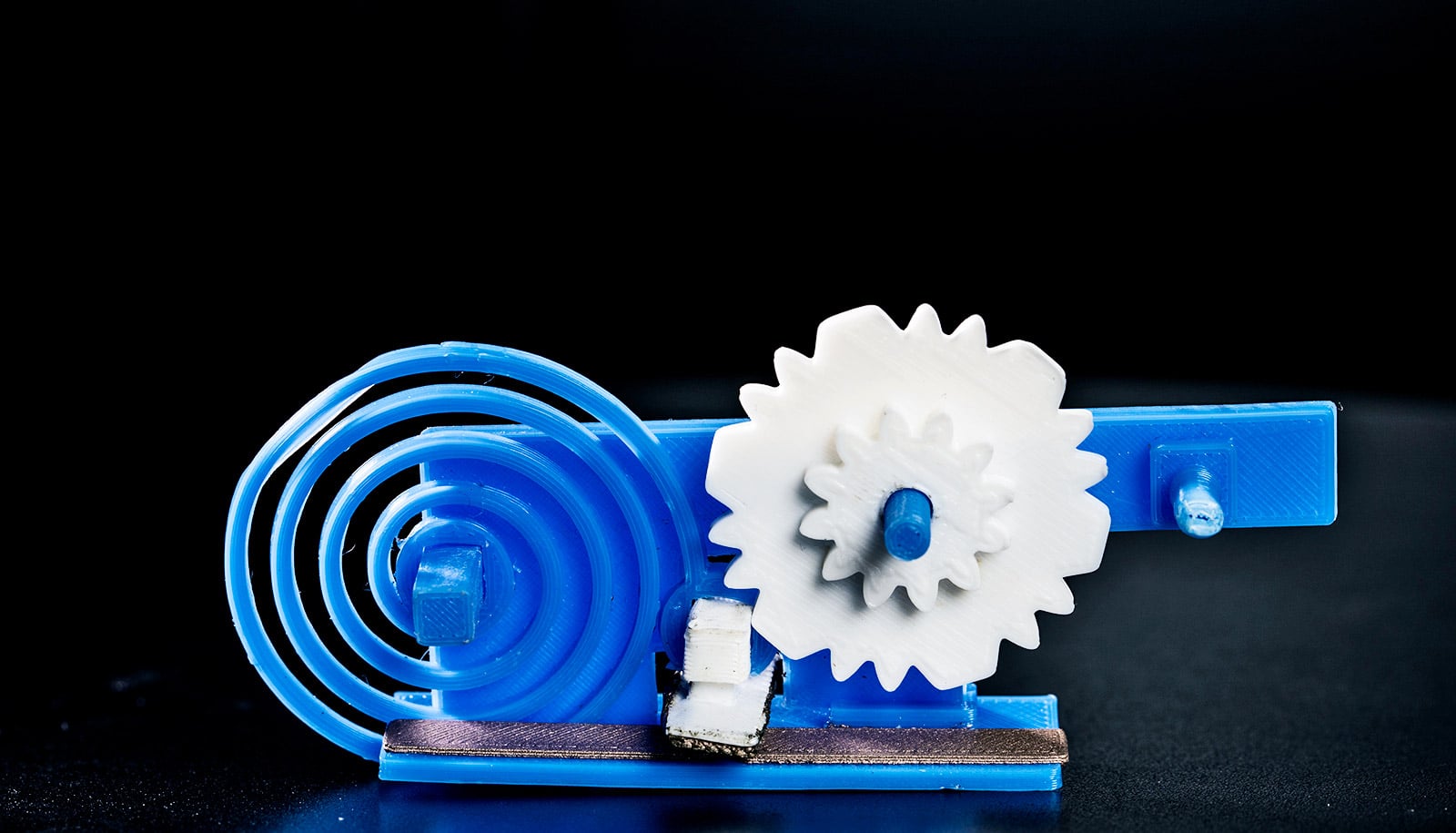

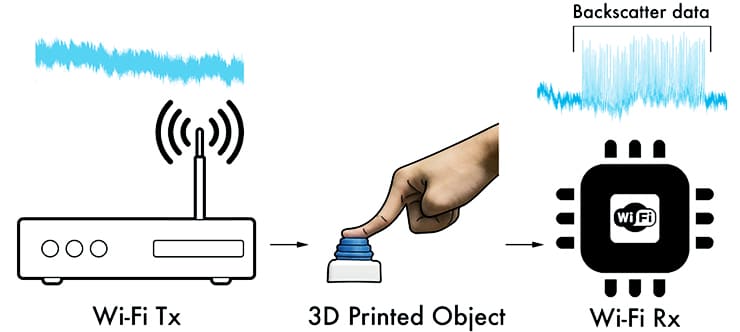

To 3D print objects that can communicate with commercial Wi-Fi receivers, the team employed backscatter techniques that allow devices to exchange information. In this case, the team replaced some functions normally performed by electrical components with mechanical motion activated by springs, gears, switches, and other parts that can be 3D printed—borrowing from principles that allow battery-free watches to keep time.

Backscatter systems use an antenna to transmit data by reflecting radio signals emitted by a Wi-Fi router or another device. A Wi-Fi receiver can decode information embedded in those reflected patterns. In this case, the antenna is contained in a 3D printed object made of conductive printing filament that mixes plastic with copper.

Physical motion—pushing a button, laundry soap flowing out of a bottle, turning a knob, removing a hammer from a weighted tool bench—triggers gears and springs elsewhere in the 3D printed object that cause a conductive switch to intermittently connect or disconnect with the antenna and change its reflective state.

The presence or absence of the tooth on a gear encodes information—in the form of 1s and 0s. Energy from a coiled spring drives the gear system, and the width and pattern of gear teeth control how long the backscatter switch makes contact with the antenna, creating patterns of reflected signals that a Wi-Fi receiver can decode.

“As you pour detergent out of a Tide bottle, for instance, the speed at which the gears are turning tells you how much soap is flowing out. The interaction between the 3D printed switch and antenna wirelessly transmits that data,” says senior author Shyam Gollakota, an associate professor in the Paul G. Allen School of Computer Science & Engineering at the University of Washington.

“Then the receiver can track how much detergent you have left and when it dips below a certain amount, it can automatically send a message to your Amazon app to order more.”

Printing smart plastic

The team from the university’s Networks & Mobile Systems Lab 3D printed several different tools that were able to sense and send information successfully to other connected devices: a wind meter, a water flow meter, and a scale. They also printed a flow meter that was used to track and order laundry soap, and a test tube holder that could be used for either managing inventory or measuring the amount of liquid in each test tube.

Algorithm cuts 3D printing time in half

They also 3D printed Wi-Fi input widgets such as buttons, knobs, and sliders that can be customized to communicate with other smart devices in the home and enable a rich ecosystem of “talking objects” that can seamlessly sense and interact with their surroundings.

Using a different type of 3D printing filament that combines plastic with iron, the team also leveraged magnetic properties to invisibly encode static information in 3D printed objects—which could range from barcode identification for inventory purposes or information about the object that tells a robot how to interact with it.

“It looks like a regular 3D-printed object but there’s invisible information inside that can be read with your smartphone,” says Allen School doctoral student and co-lead author Justin Chan.

The system is described in a paper the researchers presented November 30 at the Association for Computing Machinery’s SIGGRAPH Conference and Exhibition on Computer Graphics and Interactive Techniques in Asia.

Funding came from the National Science Foundation, the Alfred P. Sloan Fellowship, and Google.

Source: University of Washington