Researchers have developed a lightweight engine to power muscle-mimicking soft robots for use in assistive devices.

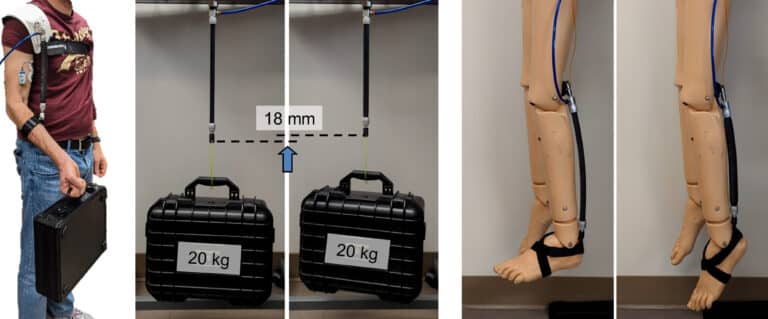

What sets the new engine apart is its ability to generate significant force without being tethered to an external power source.

“Soft robots that are powered by fluid engines—such as hydraulic or pneumatic action—can be used to mimic the behavior of muscle in ways that rigid robots cannot,” says Hao Su, corresponding author of a paper on the work and an associate professor of mechanical and aerospace engineering at North Carolina State University.

“This makes these robots particularly attractive for use in assistive devices that improve people’s ability to move their upper or lower limbs.”

However, most fluid engines are physically connected to an external power source, such as a large air compressor. That significantly limits their utility. And previous fluid engines that were not tethered to external power sources were not able to generate much force, which also limited their utility.

“Our work here addresses both of those challenges,” Su says. “Our fluidic engine is not tethered to an external source but can still generate up to 580 Newtons of force.”

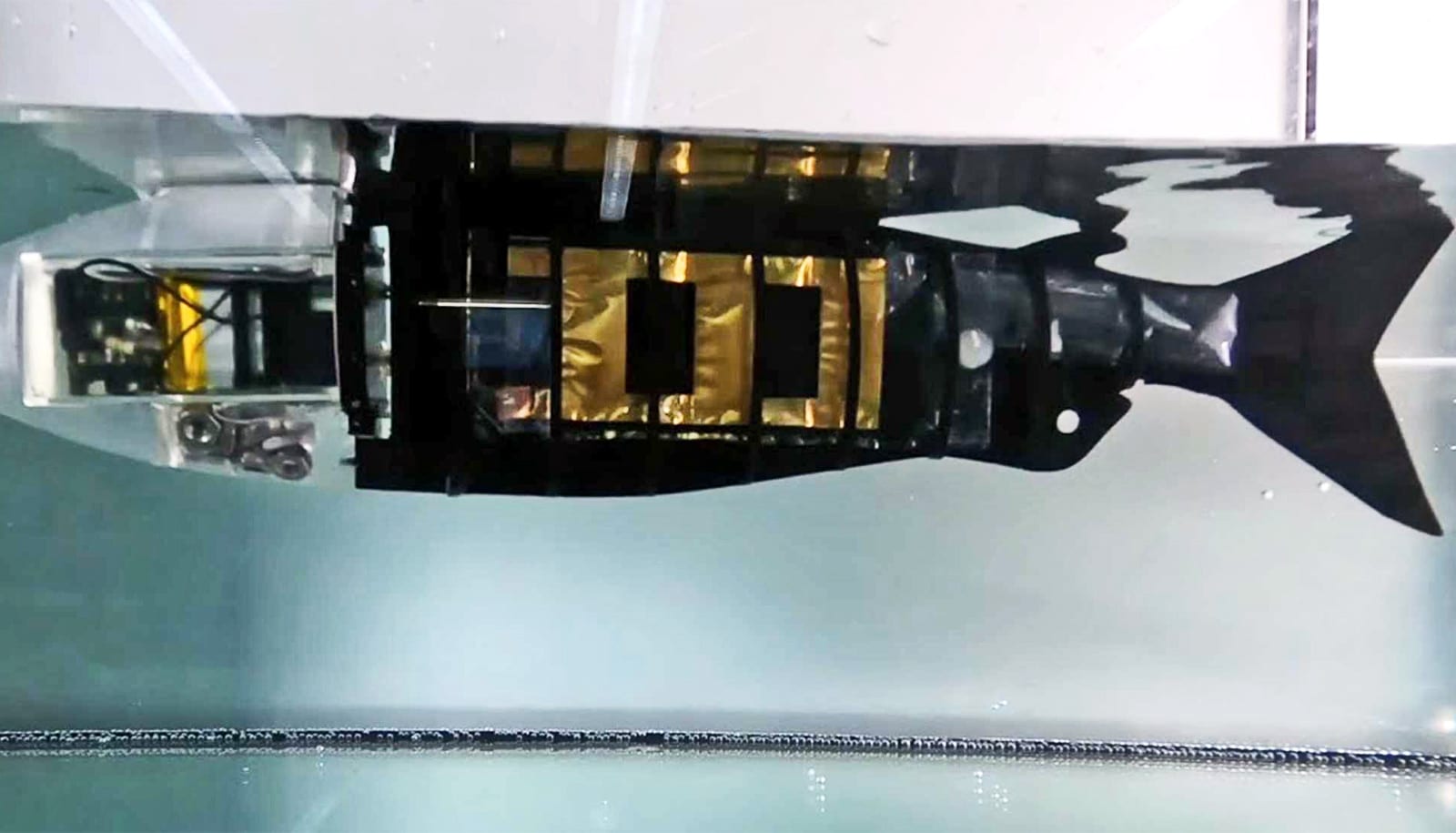

The new engine works by pumping oil into and out of a chamber in a soft robot, causing the soft robot to act as an artificial muscle that is flexing and relaxing. The fluidic engine’s pump is driven by a battery-powered high-torque motor that allows it to generate significant pressure, enabling the artificial muscle to exert significant force.

In proof-of-concept testing, the researchers not only assessed the amount of force the new engine can generate, but how efficiently the engine converts electrical power into fluidic power.

“We found that we were able to generate an unprecedented amount of force for an untethered engine, while still keeping the weight of the fluidic engine low,” says Antonio Di Lallo, first author of the paper and a postdoctoral researcher at NC State. “And the maximum efficiency of our fluidic engine is higher than previous portable, untethered engines.”

The paper appears in the journal Advanced Intelligent Systems.

Additional coauthors are from NC State; Sandia National Laboratories; and the University of California, Berkeley.

Support for the work came from the National Science Foundation; the National Institute on Disability, Independent Living, and Rehabilitation Research; and Amazon Robotics.

Source: NC State